Automatic testing system used for testing fresh mixing performance of concrete

An automatic test system, concrete technology, applied in flow characteristics, measuring devices, instruments, etc., can solve the problems of concrete without good workability measurement methods and test systems, and achieve the effects of simple measurement methods, convenient use, and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

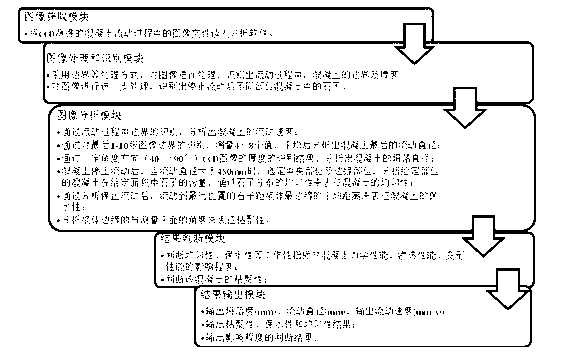

[0021] Design a typical combination such as C50. Under the condition that the amount of other raw materials is the same, the slump and cohesiveness can be controlled by adjusting the amount of admixture. For example, the slump is controlled to 180~260mm, and the cohesion and water retention are good. or bad. Stir 50-100L. After the mixing is completed, test the slump performance according to the standard method of consistency test according to the national standard GB / T 50080-2002, or the improved slump method based on this. Install the measurement system on the measurement plane, press the trigger button of the automatic test system while lifting the slump cylinder or opening the valve, the automatic test system will automatically record the whole process of slurry flow and obtain all the data of the working performance . And use wireless or wired methods to transmit the measurement results to the analysis and processing software, and the software can automatically obtain pa...

Embodiment 1

[0024] Concrete C50 for a certain project has a design slump of 200±20mm, which requires good cohesion and water retention. The design mix ratio is: P·O cement 400kg / m 3 , Class I fly ash 50 kg / m 3 , S95 grade slag fine powder 50 kg / m 3 , sand 659 kg / m 3 , gravel 1112 kg / m 3 , water 154 kg / m 3 , and add an appropriate amount of admixture to control the workability. Stir 30L in the laboratory.

[0025] According to the national standard GB / T 50080-2002, the slump test is carried out on the flat plate, and the material is loaded in layers and compacted according to the requirements. Place the automatic test system in front of the slump tester, and press the start button of the test system while lifting the slump.

[0026] Wait for the slurry to stop flowing and the test system to stop. The measurement image is transmitted to the data processing system through the image acquisition module in a wireless or wired manner (see attached figure 1 )superior. Select the perform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com