Hydraulic tunnel inverted arch operation trolley and inverted arch construction method

A workbench and tunnel technology, applied in tunnels, tunnel linings, earthwork drilling, etc., can solve the problems of large labor input, discount of formwork support, formwork offset, etc., to reduce labor intensity, improve quality, and improve progress. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

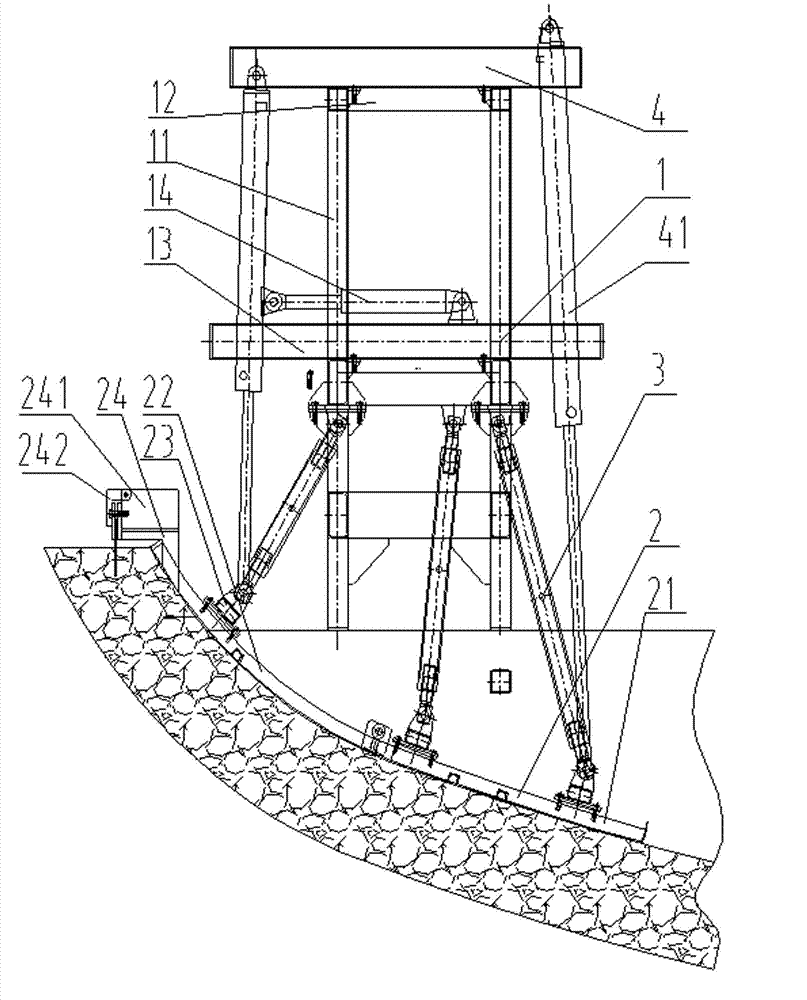

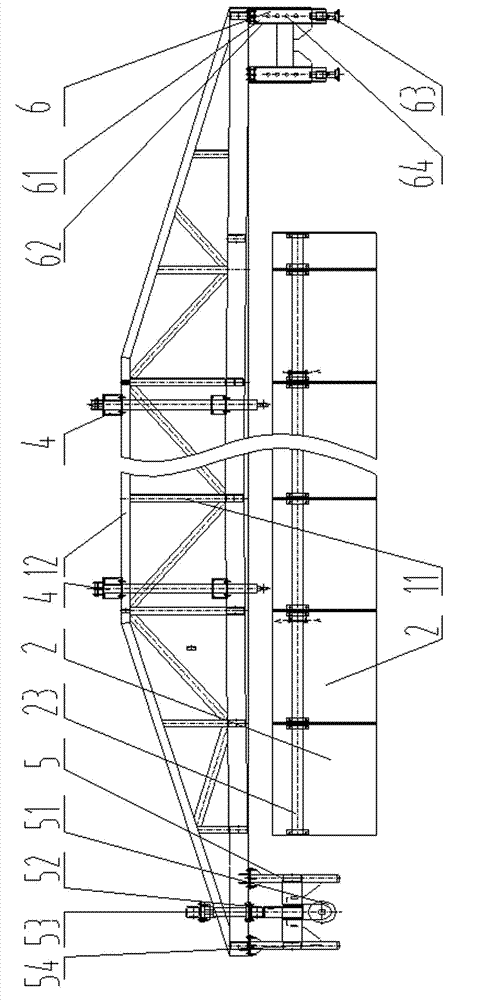

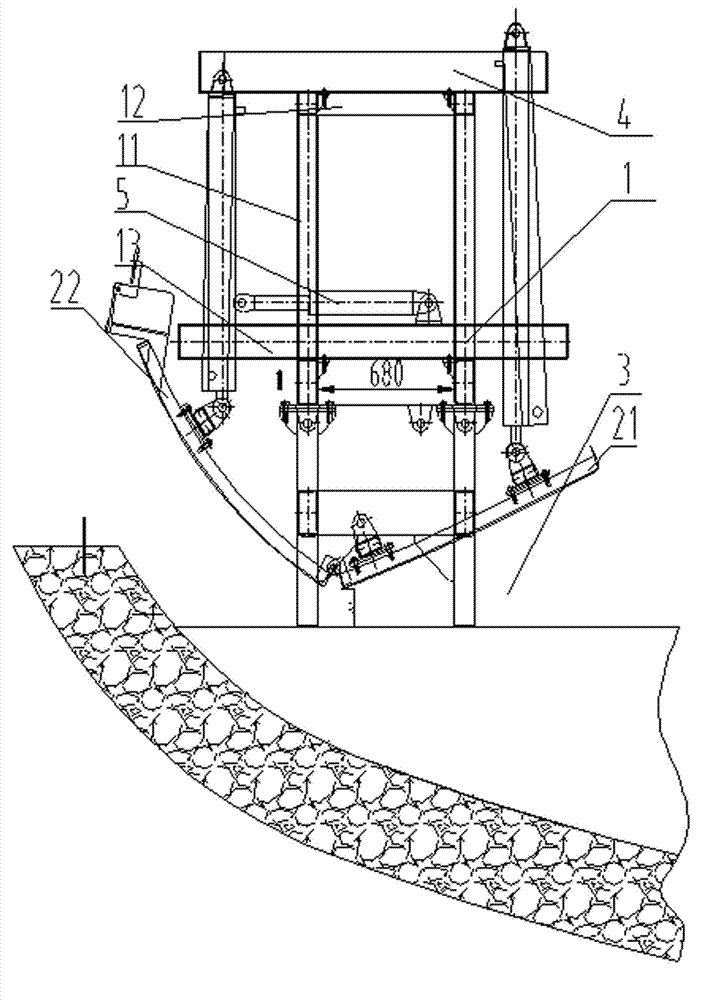

[0024] Such as figure 1 , 2 As shown, the present invention includes a main beam 1, a plurality of templates 2 and three rows of screw mandrels 3, each of the templates 2 includes a first template 21 and a second template 22, the first template 21 and the second template 22 are hinged, and multiple Two templates 2 are connected as a whole in a hinged manner; the main beam 1 includes a cross beam 12 and a vertical support 11, and the cross beam 12 and the vertical support 11 are fixedly connected as one; the upper end of the main beam 1 is provided with Two tailstocks 4, the two ends of each tailstock 3 are respectively hinged with the upper end of a lifting cylinder 41, and the lower end of the lifting cylinder 41 is hinged with the corresponding template 2 respectively. The main beam 1 is also provided with two control frames 13 corresponding to the two tailstocks 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com