Anti-pollution thermal washing and paraffin removal unit with dosage channel

An anti-pollution and passage technology, which is applied in the direction of cleaning equipment, wellbore/well parts, earthwork drilling and mining, etc., to achieve the effects of reducing consumption, saving costs, and saving time for well cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

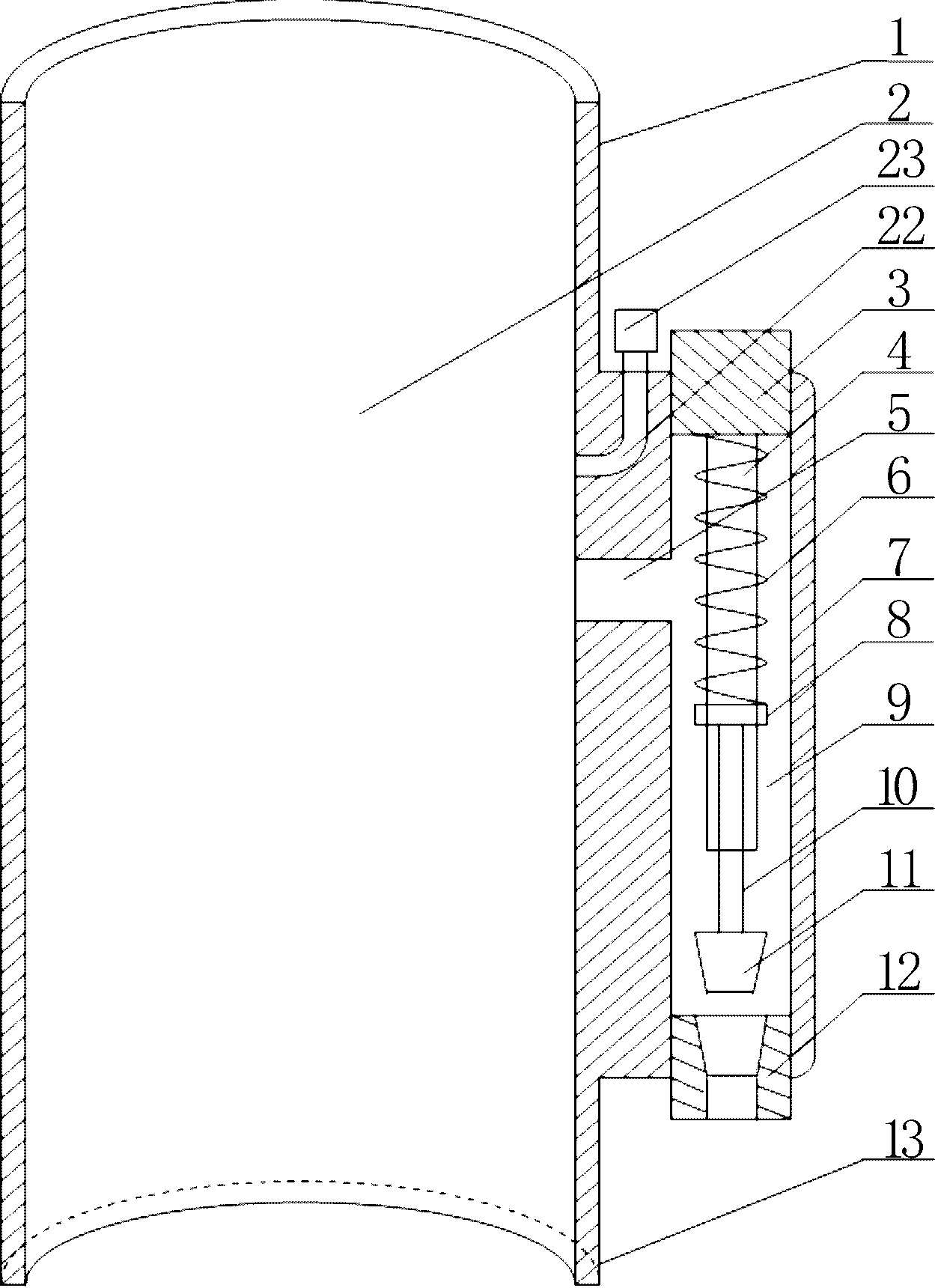

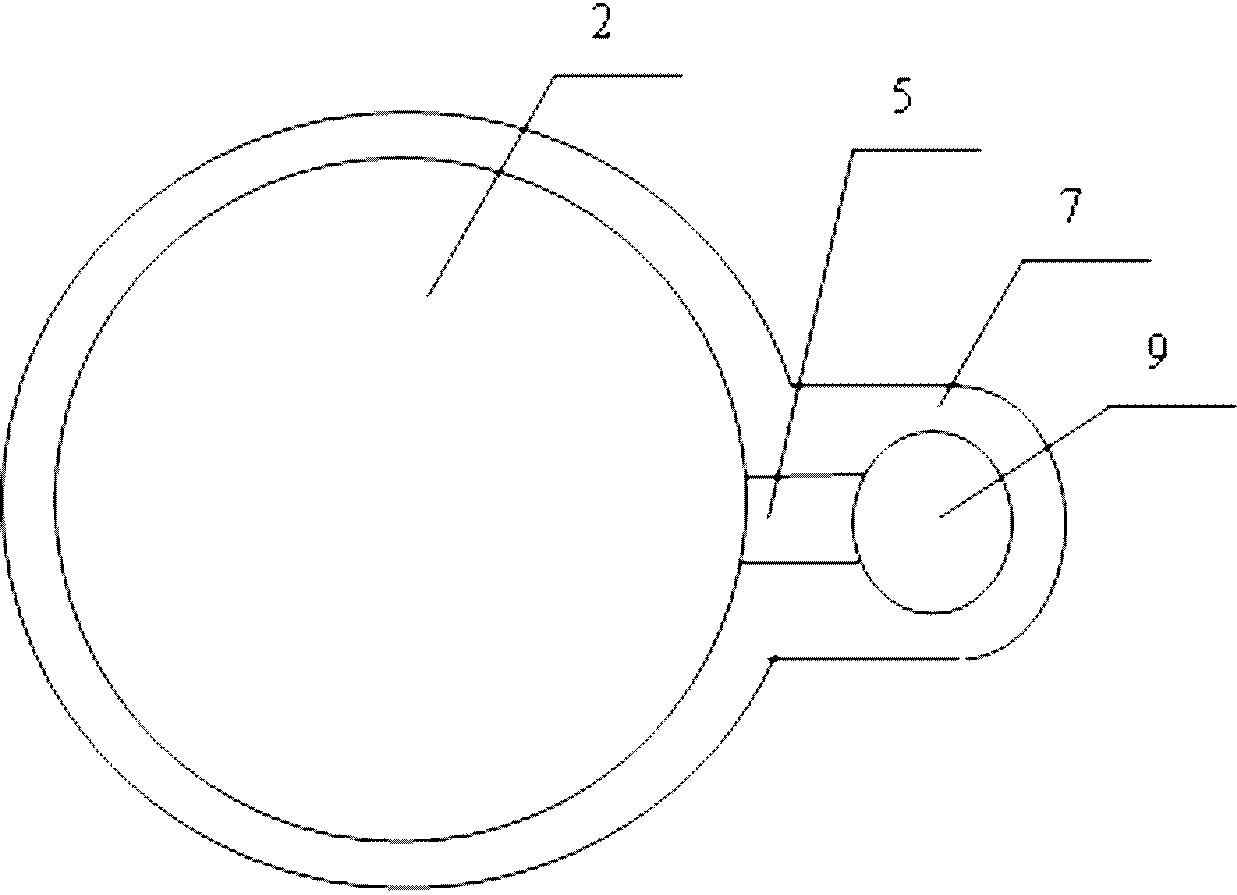

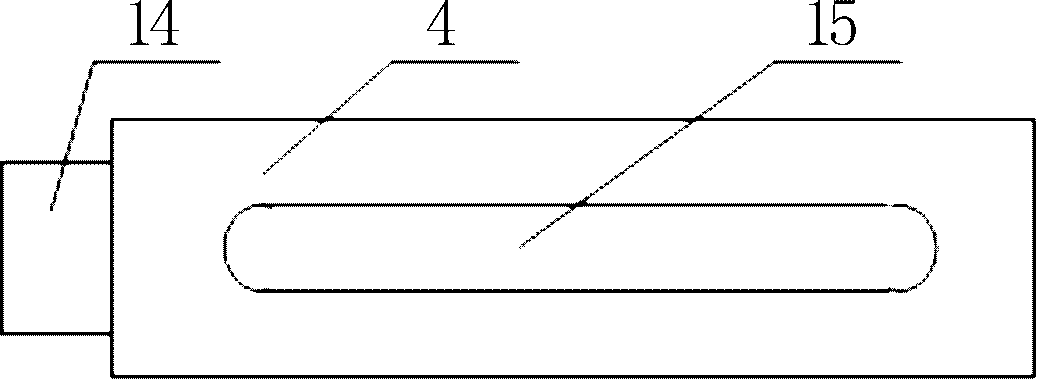

[0023] Such as figure 1 , 2 , 3, 4, and 5, the anti-pollution hot-washing and wax-removing device with drug injection channel consists of an upper joint 1, a central tube 2, an upper plug 3, a guide tube 4, a channel 5, a pressure spring 6, and an eccentric body 7. The limit bayonet pin 8, the cavity 9, the push rod 10, the tapered plug 11, the lower screw plug 12 and the lower joint 13 are composed. The upper joint 1 and the lower joint 13 of the central pipe 2 are used to connect the upper and lower oil pipes. The inner diameter of the central pipe 2 is the same as the inner diameter of the oil pipe. An eccentric body 7 is arranged on one side of the central pipe 2. There is a cavity 9 connecting up and down in the middle of the eccentric body 7. There is a channel 5 communicating between the cavity and the central tube, the upper end of the cavity is sealed by the upper screw plug 3, the threaded joint 14 at the upper end of the guide tube 4 is set in the screw hole at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com