Cracking protection method for concrete dams

A technology of concrete and dam body, applied in coastline protection, water conservancy engineering, sea area engineering, etc., can solve the problem of high cost of temperature control, achieve the effects of reducing project investment, improving stress state, and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

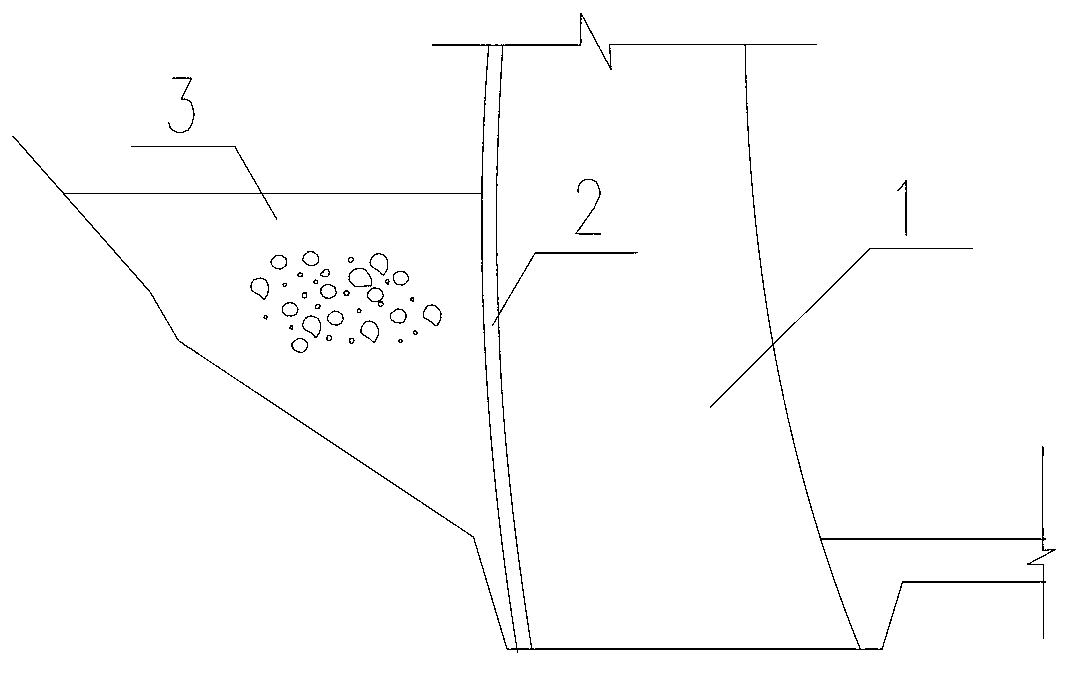

[0016] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0017] The present invention makes full use of the characteristics that the silt entering the dam after operation will cause the formation of hyperpycnal flow in front of the dam, which will increase the water temperature at the bottom of the dam and will form silt deposits in front of the dam, and artificially fill in the silt deposit range in front of the dam body in advance. The combination of sand and thermal insulation materials plays a protective role in preventing cracking of the dam body, thereby reducing the requirement on the temperature difference between the dam body and the outside world, and simplifying the temperature control measures. Specifically:

[0018] (1) Thermal insulation material is provided on the surface of the upstream side of the dam body; (2) Sand is filled outside the thermal insulation material in the restricted a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com