Integrated treatment method of corn alcohol wastewater

A technology of alcohol wastewater and treatment methods, which is applied in the directions of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., and can solve the problems of non-standard wastewater, high concentration of suspended solids, and long anaerobic treatment time and other problems, to achieve the effect of low treatment cost, simple operation and high biochemical efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

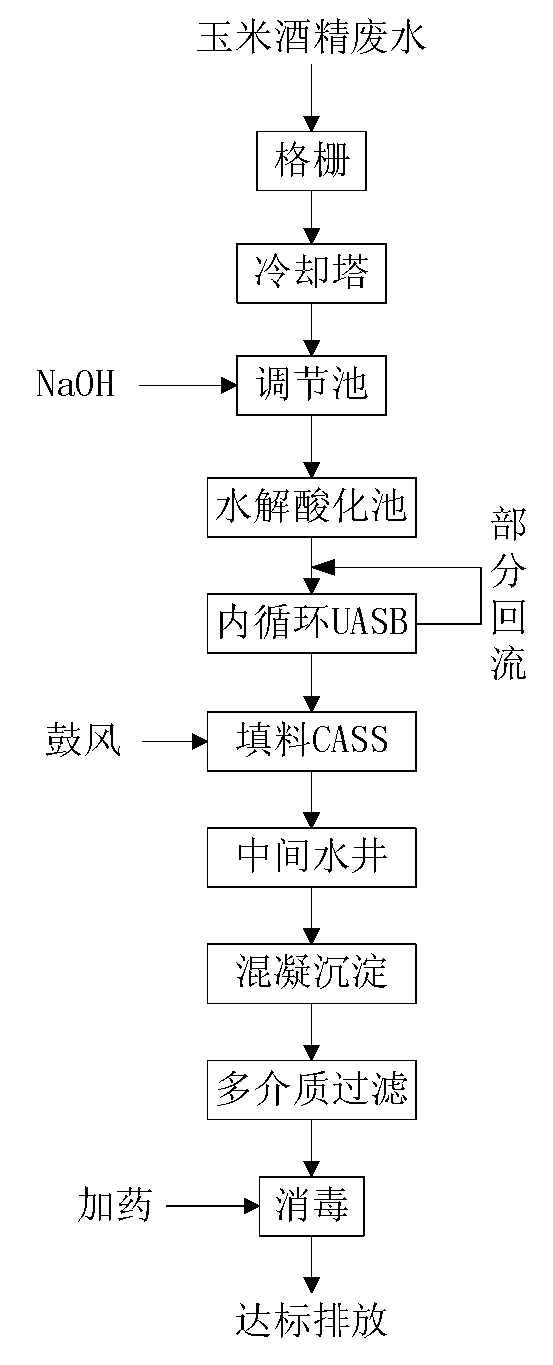

Image

Examples

experiment example 1

[0041] A corn alcohol factory in Henan adopts the method of the present invention to treat the waste water of the factory. The raw water COD is about 3500 mg / L, and the designed treatment capacity is 2000m 3 , the surface load of the adjustment pool is 0.8m 3 / m 2 h, the hydraulic retention time is 2.5h, the hydraulic retention time of the hydrolysis regulating tank is 10h, and the volume load of the internal circulation UASB reactor is 4.75 kgCOD / m 3 d, the ascending flow rate is 0.45m / h, and the volume load of the CASS tank is 0.4kgBOD / m 3 d, dissolved oxygen 2.5mg / L, sludge concentration 4500mg / L, aerobic effluent COD average 60mg / L, NH 3 -N average is 0.8mg / L, every treatment 1m 3 The dosage of waste water PAS is 60g, and the multi-media filter is filled with gravel, quartz sand, anthracite and other media from top to bottom. 3 -N is 0.7mg / L on average, meeting the supplementary water requirements for industrial circulating cooling water.

experiment example 2

[0043] A corn alcohol factory in Henan adopts the method of the present invention to treat the waste water of the factory. The raw water COD is about 10000 mg / L, and the designed treatment capacity is 2000m 3 , the surface load of the adjustment pool is 0.8m 3 / m 2 h, the hydraulic retention time is 2.5h, the hydraulic retention time of the hydrolysis regulating tank is 12h, and the volume load of the internal circulation UASB reactor is 13.4 kgCOD / m 3 d, the ascending flow rate is 0.3m / h, and the volume load of the CASS pool is 0.5kgBOD / m 3 d, dissolved oxygen 2.5mg / L, sludge concentration 4500mg / L, aerobic effluent COD average 65mg / L, NH 3 -N is 1.0mg / L on average, every treatment 1m 3 The dosage of waste water PAS is 60g. The multi-media filter is filled with gravel, quartz sand, anthracite and other media from top to bottom. The media filling height is 1.2m. After disinfection treatment, the average COD of effluent is 50mg / L, 3 -N is 0.8mg / L on average, meeting the sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com