Pipe fitting bar code scanning device

A barcode scanning and barcode technology, which is applied in the direction of auxiliary devices, cooperative operation devices, computer parts, etc., can solve the problems of reducing the welding quality of pipe fittings and pipe fitting loss, and achieve the effect of reducing loss and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

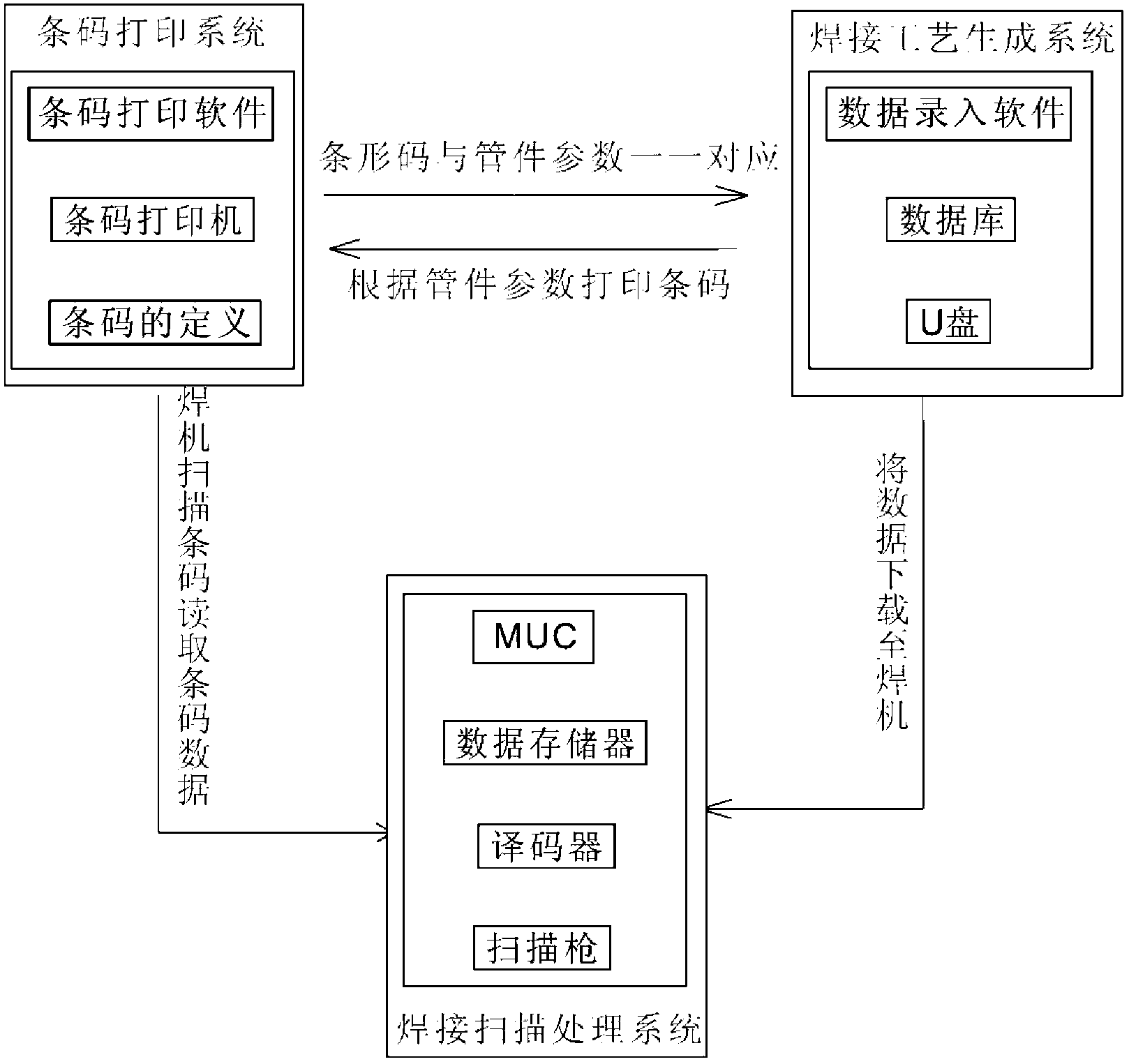

[0048] Such as figure 1 As shown, a barcode scanning device for pipe fittings according to an embodiment of the present invention includes:

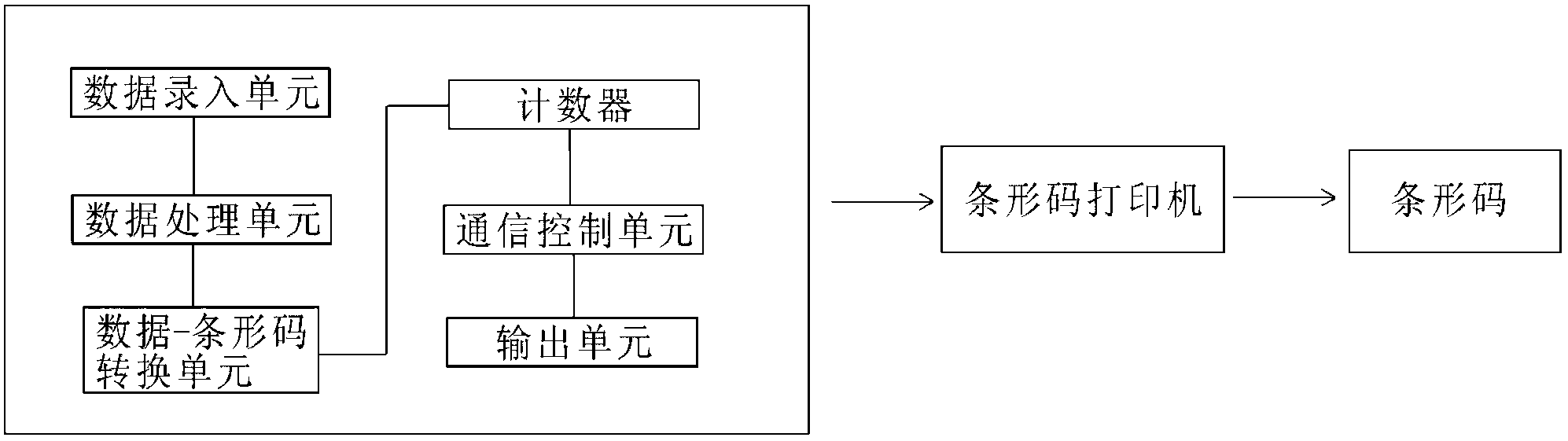

[0049] Barcode printing system, which inputs various parameters of pipe fittings, converts various parameters of pipe fittings into bar code information and outputs it to a bar code printer to print out the bar code, and then paste the bar code to the corresponding key position;

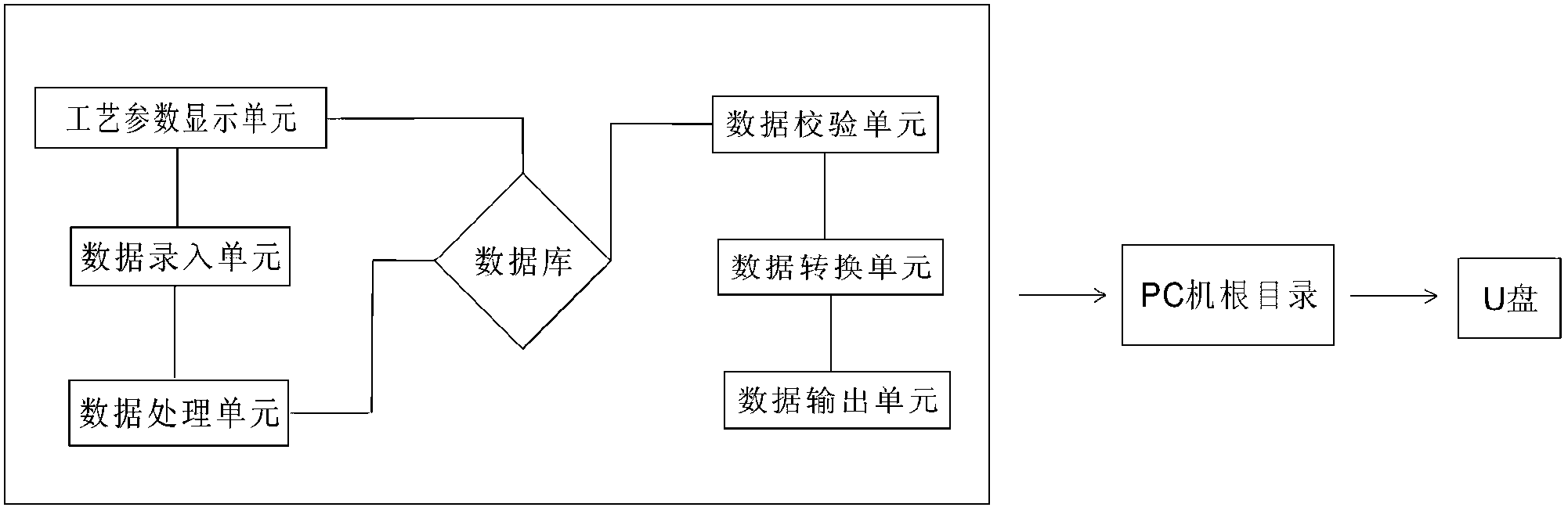

[0050] Welding process generation system, which selects the parameters of the pipe fittings to be modified, enters the welding parameters, resistance, temperature coefficient and other information of the pipe fittings, and stores the above data information to generate the process parameters. At the same time, each pipe fitting parameter stored in the database undergoes proofreading, correction and conversion Complete welding procedure code file; and

[0051] Welding scanning processing system, which reads the bar code information on the pipe fittings, the read bar cod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com