Method for measuring content of nickel in low nickel iron

A method of determination, technology of nickel content, applied in the direction of color/spectral characteristic measurement, etc., can solve the problems of cumbersome operation and long time consumption, and achieve the effect of easy promotion, short time consumption and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

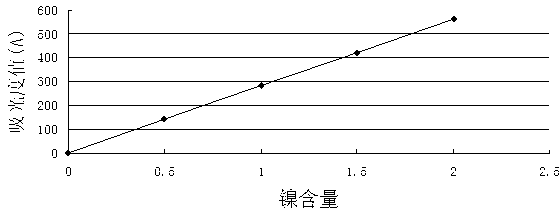

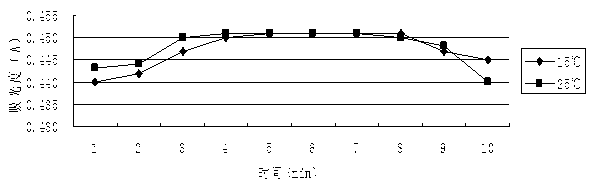

Method used

Image

Examples

Embodiment 1

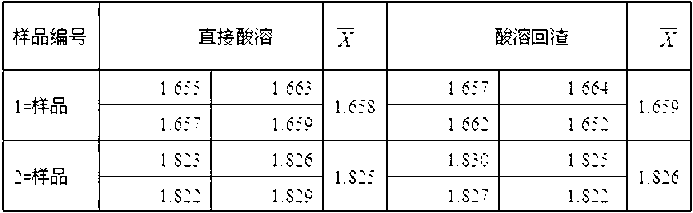

[0042] Use the nickel-iron standard sample JSS760-3 to make the standard solution with a given value of 1.956%, and measure continuously 8 times respectively according to the assay method of the present invention, and the assay results of nickel are shown in Table 4.

[0043] Table 4 Determination results of nickel in standard solution

[0044]

[0045] As can be seen from the data in Table 4, the precision and accuracy measured by the assay method of the present invention are all very good.

Embodiment 2

[0047] The low-nickel-iron standard sample YSBC28040a-08 was continuously measured 8 times according to the method of the present invention, and the results of nickel determination are shown in Table 5.

[0048] Table 5 Determination results of nickel in low-nickel-iron standard samples

[0049]

[0050] As can be seen from the data in Table 5, the average value of the assay results of the present invention is consistent with the given value of the standard sample, and the analytical precision and accuracy are all good.

[0051] The present invention has the following effects: First, the present invention can accurately measure the content of nickel in low-nickel iron. Second, the present invention is time-consuming and has a short analysis period, which can be completed in about 1 hour. Three, the method of the present invention is simple, easy to operate, few steps, with low cost, easy to popularize.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com