Cold and hot water double-loop air-conditioning system

An air-conditioning system and double-circuit technology, which is applied in air-conditioning systems, refrigerators, household heating, etc., can solve the problems of energy waste, increase the temperature difference of heat exchange in heating rooms in winter, and unreasonable problems, so as to maintain indoor air quality and eliminate noise , the effect of saving indoor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

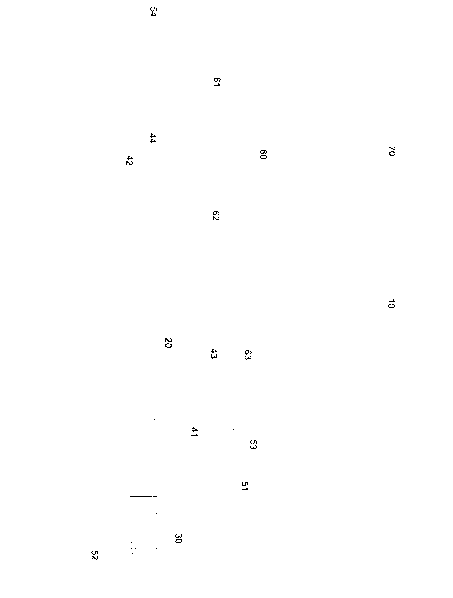

[0022] Combine below figure 1Describe in detail the specific implementation of the winter heating and energy-saving operation of a cold and hot water dual-circuit air-conditioning system provided by the present invention. During winter heating operation, the cold water supply switching valve 43 placed in the cold water supply pipeline 41 and the cold water return switching valve 44 placed in the cold water return pipeline 42 are in a closed state, and the hot water switching valve 44 placed in the hot water supply pipeline 51 is closed. The valve 53 and the hot water return conversion valve 54 placed in the hot water return line 52 are in an open state. Therefore, during the winter heating process, the cold water terminal heat exchange equipment 20 does not work, and the heat pump type cold (hot) water air conditioner unit 10 Then it will switch to the heating working state and provide hot water to the natural heat exchanging hot water terminal heat exchanging equipment 30. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com