Axial flow type single-seat adjusting valve

An axial flow, regulating valve technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of valve adjustment performance affecting valve life, large flow resistance coefficient of zigzag valve body structure, and reduced valve flow coefficient, etc. Achieve the effect of solving the scour problem, improving the adjustment performance and improving the flow coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

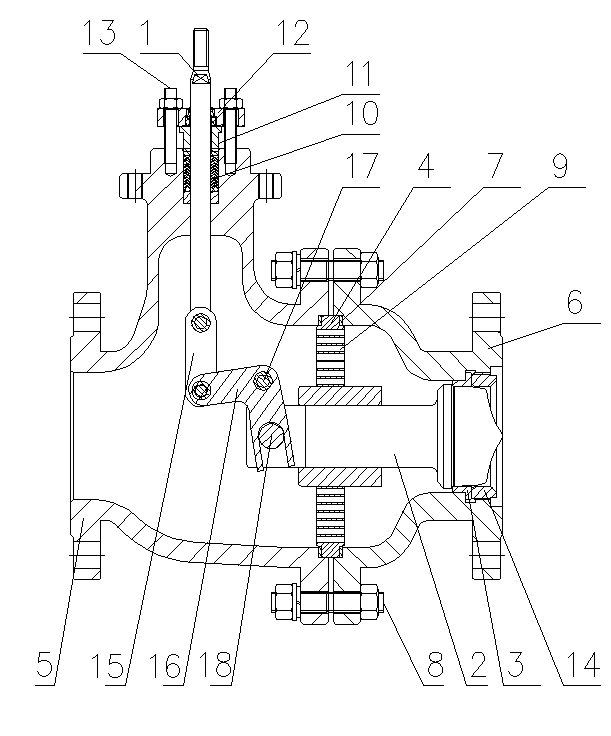

[0017] as attached figure 1 As shown, the axial-flow single-seat control valve of the present invention is mainly composed of a valve body, a packing device assembly, a valve stem 1, a valve core 2, a valve seat 3, a guide disc 4 and a transmission mechanism.

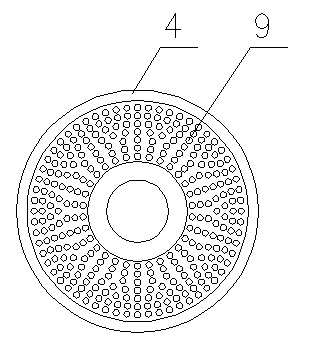

[0018] Described valve body is made of left valve body 5, right valve body 6. The liquid outlet channel of the left valve body 5 is arranged coaxially with the liquid inlet channel of the right valve body 6 . The guide plate 4 is placed between the left valve body 5 and the right valve body 6 . The guide plate 4 cooperates with the left valve body 5 and the right valve body 6 through two toothed gaskets 7, and is fixed with a stud bolt assembly 8. as attached figure 2 As shown, the guide plate 4 is provided with a noise reduction hole 9 .

[0019] There is a stuffing box on the upper part of the left valve body 5, and the valve stem 1 is arranged at the stuffing box through the stuffing device assembly. The packin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com