Sodium alginate containing high molecular weight polyguluronic acid and application thereof

A technology of polyguluronic acid and high molecular weight, applied in the direction of being fixed on/in an organic carrier, can solve the problems of insufficient guluronic acid content, low mechanical strength, low molecular weight, etc. Diffusion and transfer, large molecular weight, good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

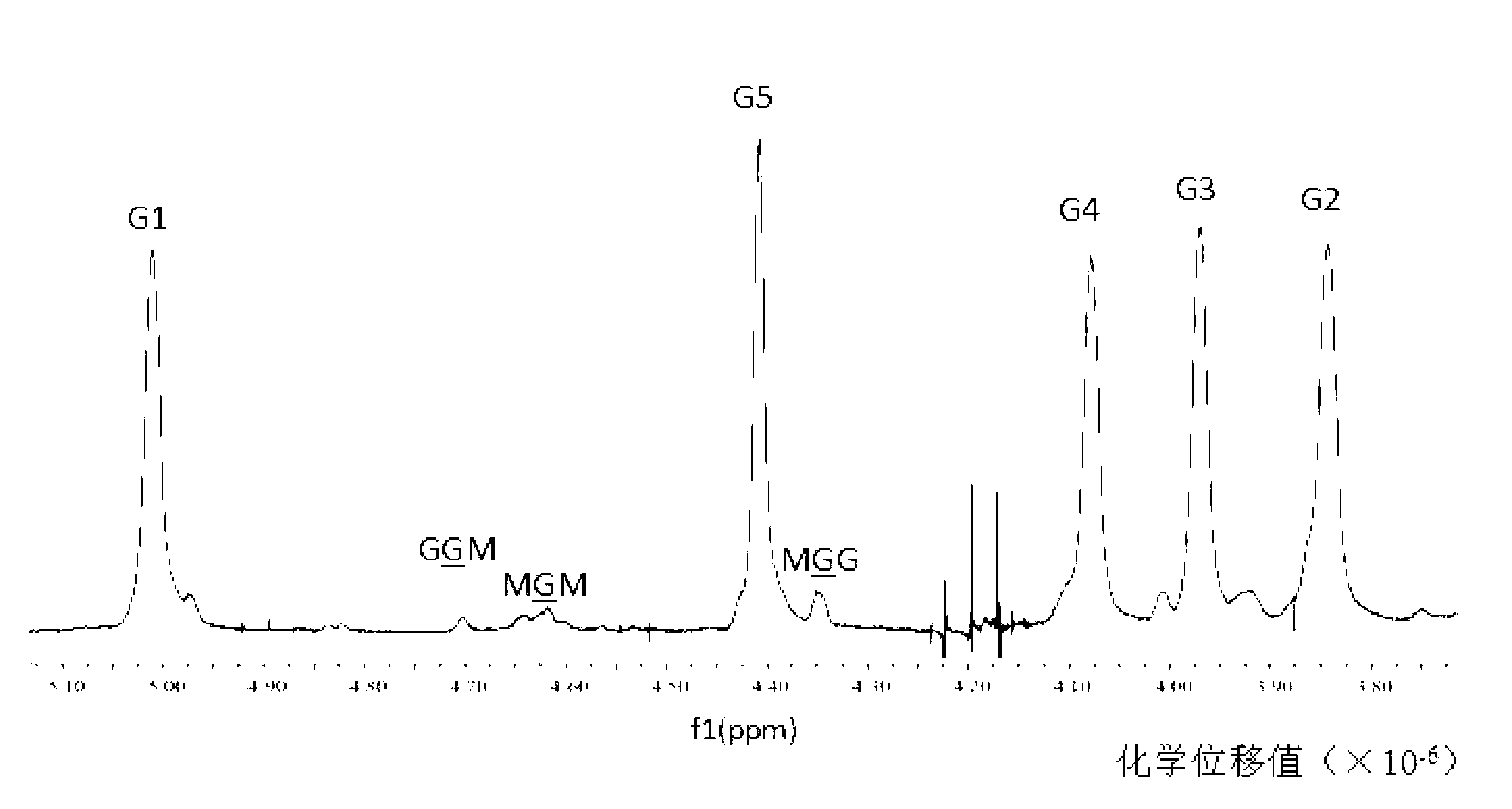

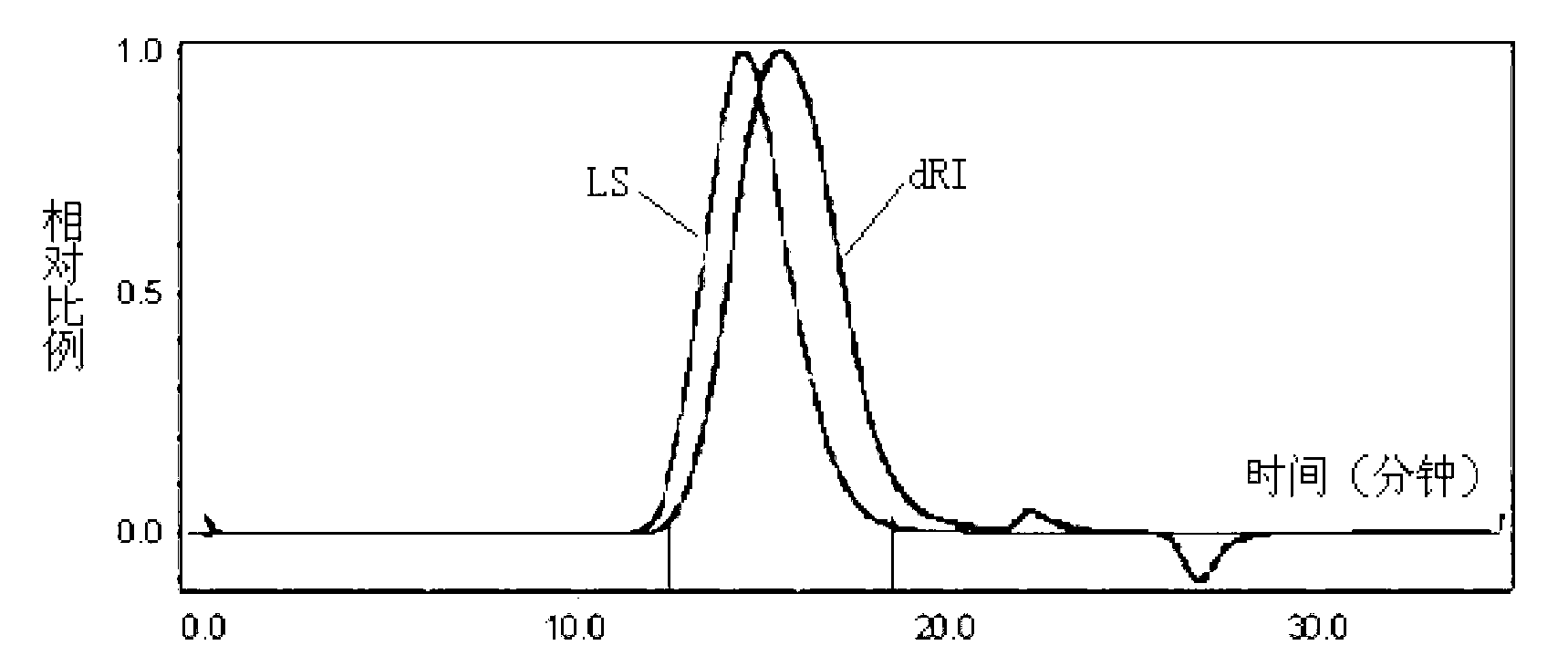

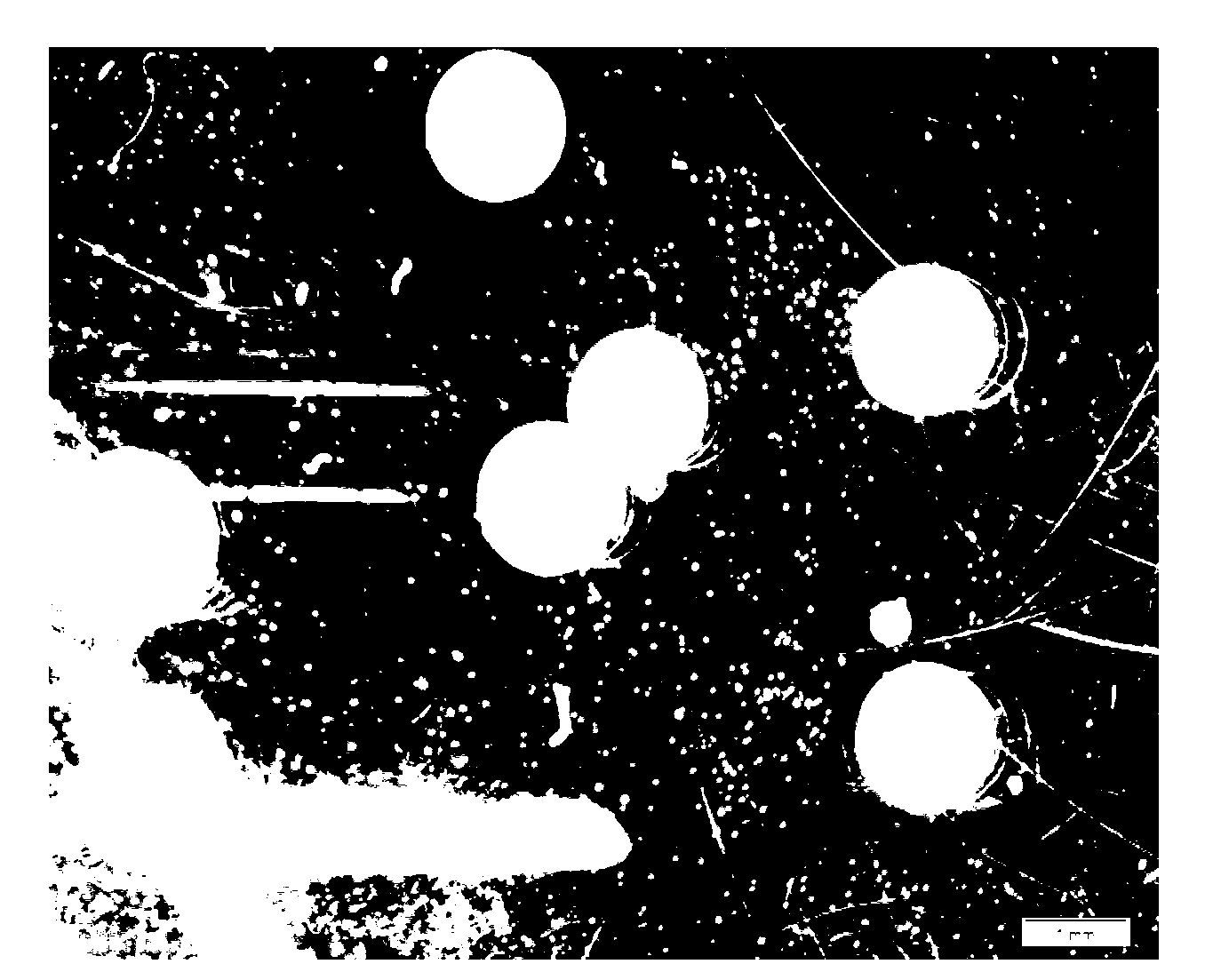

[0038] The stems and leaves of mature Chilean giant algae (Lessonia trabeculata) were selected and dried, crushed in a pulverizer, and passed through a 20-mesh sieve to obtain algae powder. Take 100g of crushed algae powder, mix the algae powder with 80wt% ethanol at a ratio of 1:10 (W / V, g / ml), then reflux and stir in a water bath at 80°C for 2 hours, discard the upper layer, and repeat the degreasing 2 times, dry the defatted algae powder. Mix the dry defatted algae powder with water at a ratio of 1:20 (W / V, g / ml), stir and extract at 80°C for 2 hours, discard the supernatant, repeat the extraction twice, and collect the algal residue by filtration. Add 2wt% sodium carbonate aqueous solution with a solid-liquid ratio of 1:30 (W / V, g / ml) to the algae residue after hot water extraction, extract at 85°C for 3 hours, centrifuge to take the supernatant, and repeat the extraction 3 times , and pool the supernatants. The supernatant was treated with 2mol·L -1After neutralizing w...

Embodiment 2

[0041] The stems and leaves of mature Chilean giant algae (Lessonia trabeculata) were selected and dried, crushed in a pulverizer, and passed through a 60-mesh sieve to obtain algae powder. Take 100g of crushed algae powder, mix the algae powder with 85wt% methanol at a ratio of 1:20 (W / V, g / ml), then reflux and stir in a water bath at 85°C for 2 hours, discard the upper layer, and repeat the degreasing 2 times, dry the defatted algae powder. Mix the dry defatted algae powder with water at a ratio of 1:20 (W / V, g / ml), stir and extract at 85°C for 3 hours, discard the supernatant, repeat the extraction twice, and collect the algal residue by filtration. Add 10wt% ammonium carbonate aqueous solution with a solid-liquid ratio of 1:20 (W / V, g / ml) to the algae residue after hot water extraction, extract at 85°C for 2 hours, centrifuge to take the supernatant, and repeat the extraction 3 times , and pool the supernatants. The supernatant was treated with 2mol·L -1 After neutraliz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com