Preparation method of graphene on SiC substrate based on Cu film annealing and chlorine reaction

A graphene and annealing technology, applied in the field of microelectronics, can solve the problems of unstable carrier mobility, inability to use large-scale production, small graphene area, etc., and achieve easy control of thickness, fast reaction rate, and low porosity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

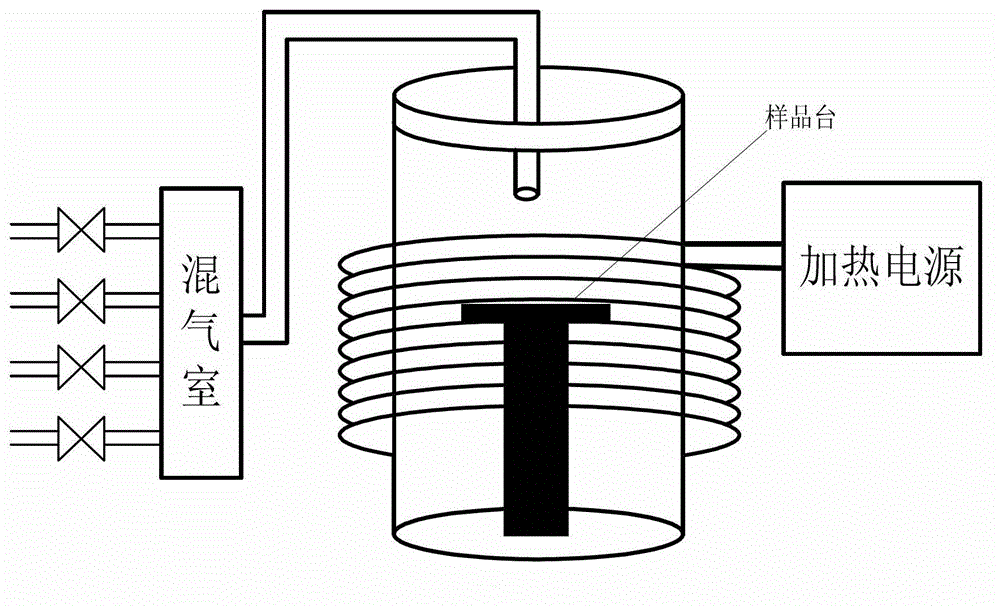

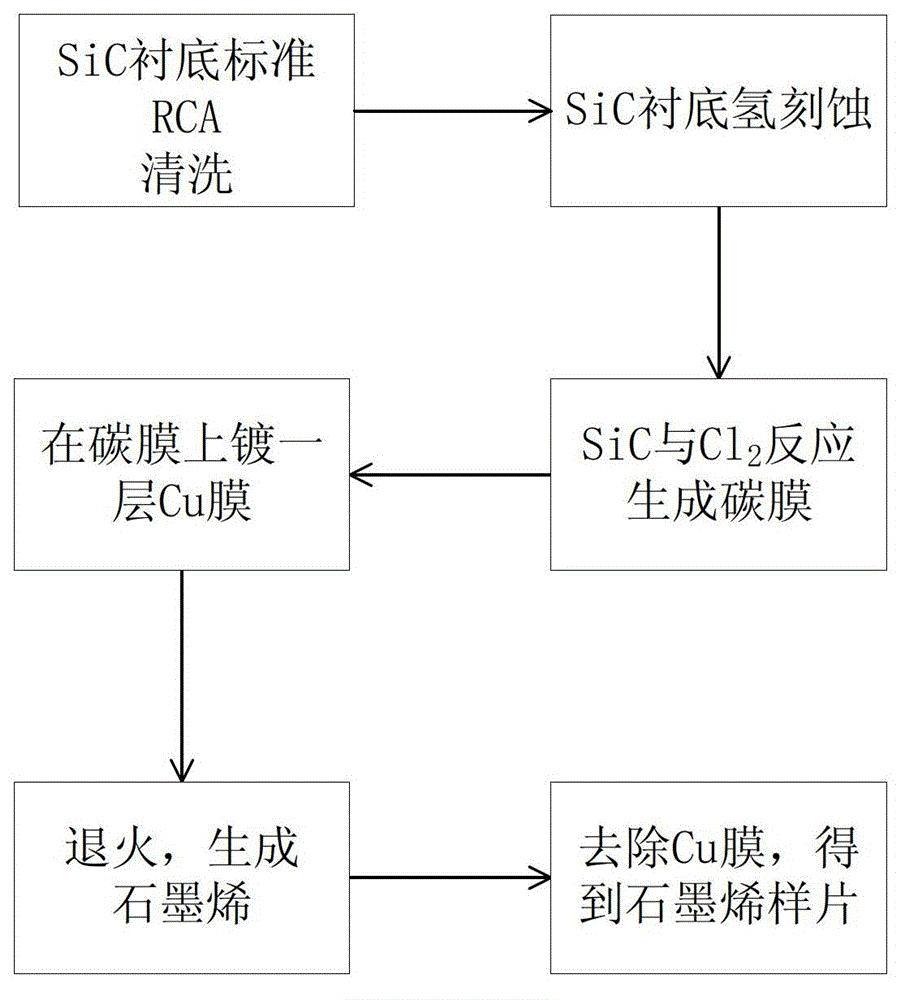

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1, making 6H-SiC and Cl 2 Reaction and Cu film annealing of graphene.

[0027] Step 1: Clean the 6H-SiC substrate to remove surface contamination.

[0028] (1.1) Using NH for 6H-SiC substrate 4 OH+H 2 o 2 Soak the sample in the reagent for 10 minutes, take it out and dry it to remove the organic residue on the surface of the sample;

[0029] (1.2) Use HCl+H on the 6H-SiC substrate after removing the surface organic residues 2 o 2 The reagent soaked the sample for 10 minutes, took it out and dried it to remove ionic contamination.

[0030] Step 2: Perform hydrogen etching on the 6H-SiC substrate.

[0031] Set the pressure in the reaction chamber to 13.3Pa, raise the temperature to 1500°C, and perform hydrogen etching treatment on 6H-SiC for 30 minutes. The hydrogen flow rate is 80L / min to remove scratches on the surface of the 6H-SiC substrate and generate nanometer-level high cycles. Sexually smooth step morphology.

[0032] Step 3: Removing hydrogen...

Embodiment 2

[0043] Embodiment 2, making 4H-SiC and Cl 2 Reaction and Cu film annealing of graphene.

[0044] Step 1: cleaning the 4H-SiC substrate to remove surface pollutants.

[0045] For 4H-SiC substrates, use NH first 4 OH+H 2 o 2 Soak the sample in the reagent for 10 minutes, take it out and dry it to remove the organic residue on the surface of the sample; then use HCl+H 2 o 2 The reagent soaked the sample for 10 minutes, took it out and dried it to remove ionic contamination.

[0046] Step 2: performing hydrogen etching on the 4H-SiC substrate.

[0047] Set the pressure in the reaction chamber to 13.3Pa, raise the temperature to 1550°C, and perform hydrogen etching on 4H-SiC for 20 minutes. The hydrogen flow rate is 80L / min to remove scratches on the surface of the 4H-SiC substrate and generate nanometer-level high cycles. Sexually smooth step morphology.

[0048] Step 3: Removing hydrogen etching residual compounds on the surface of 4H-SiC.

[0049] Lower the temperature ...

Embodiment 3

[0058] Embodiment 3, making 6H-SiC and Cl 2 Reaction and Cu film annealing of graphene.

[0059] Step A: Clean the surface of the 6H-SiC substrate, that is, use NH 4 OH+H 2 o 2 Soak the sample in the reagent for 10 minutes, take it out and dry it to remove the organic residue on the surface of the sample; then use HCl+H 2 o 2 The reagent soaked the sample for 10 minutes, took it out and dried it to remove ionic contamination.

[0060] Step B: Set the pressure in the reaction chamber to 13.3Pa, raise the temperature to 1600°C, and perform hydrogen etching treatment on 6H-SiC for 15 minutes, with a hydrogen flow rate of 80L / min, to remove scratches on the surface of the 6H-SiC substrate and produce nanoscale High periodic smooth step morphology.

[0061] Step C: Lower the temperature of the reaction chamber to 900°C, and feed SiH with a flow rate of 1ml / min 4 gas for 10 min to remove the compounds produced by hydrogen etching on the surface of 6H-SiC.

[0062] Step D: Ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com