fuel filler cap structure

A fuel filler cap and fuel filler technology, which is applied to the layout combined with the fuel supply of internal combustion engines, power devices, transportation and packaging, etc., can solve the problems of water accumulation in the fuel filler box, exposed and rusted fuel filler pipe installation bolts, etc., and achieve Conducive to assembly, solve the effect of bolt exposure and sagging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

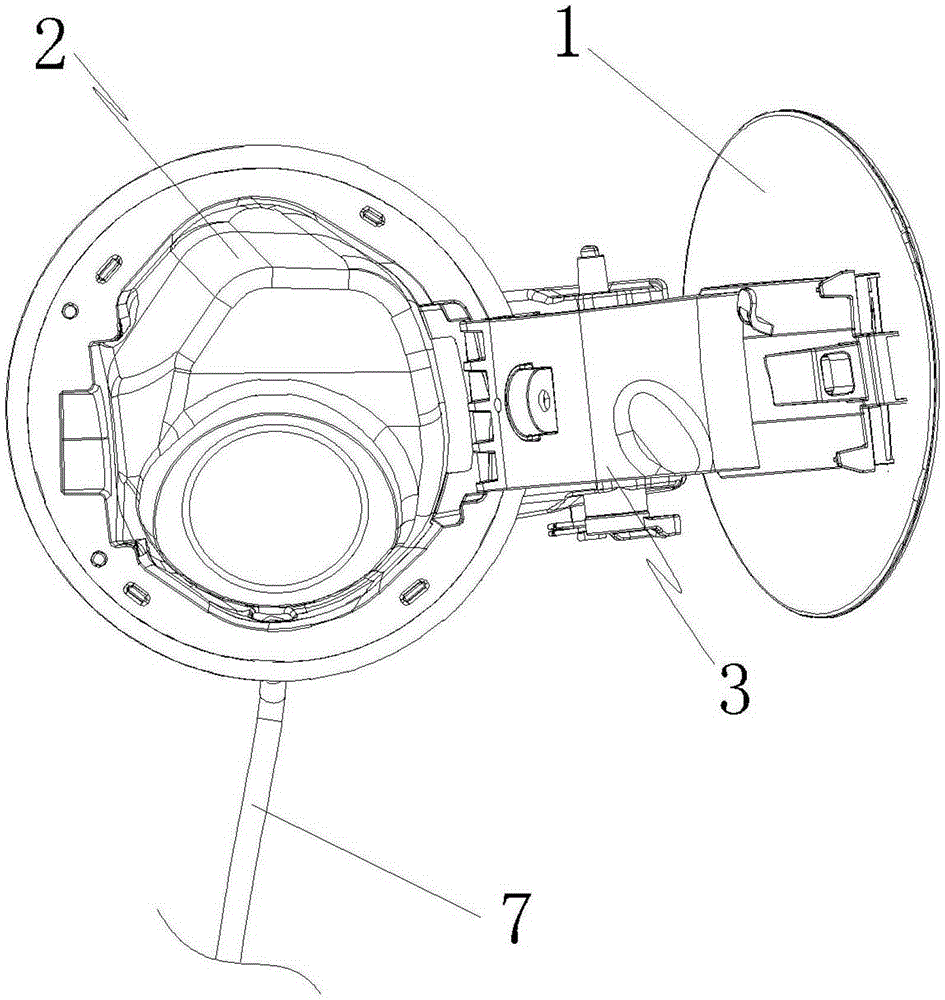

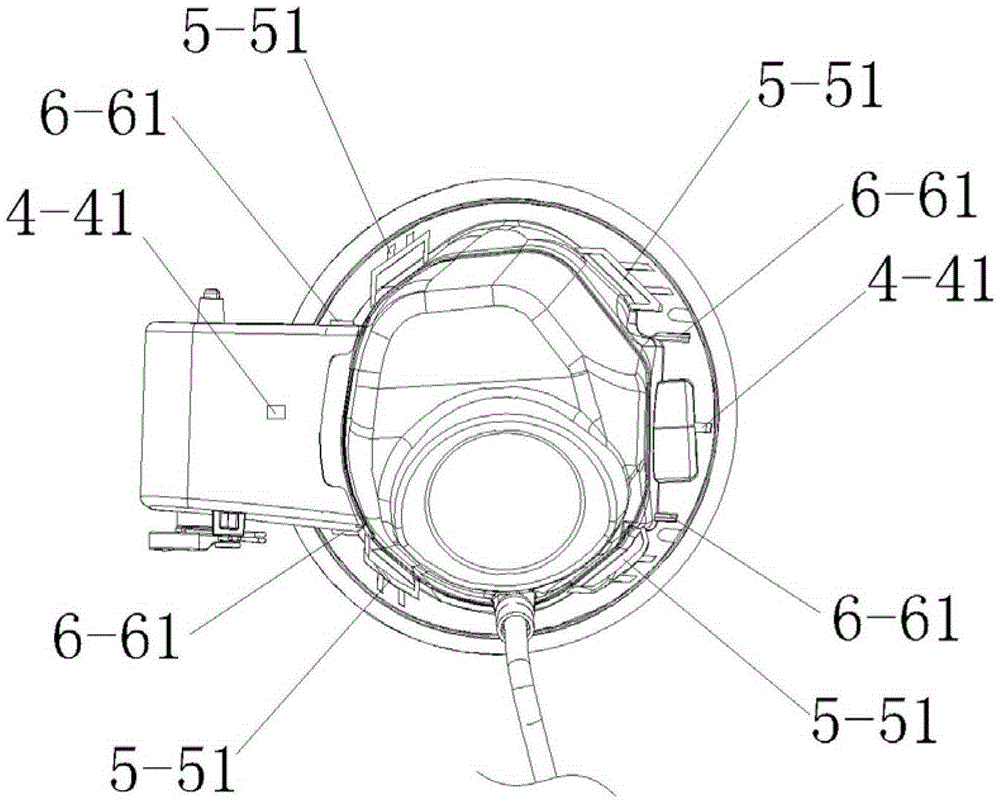

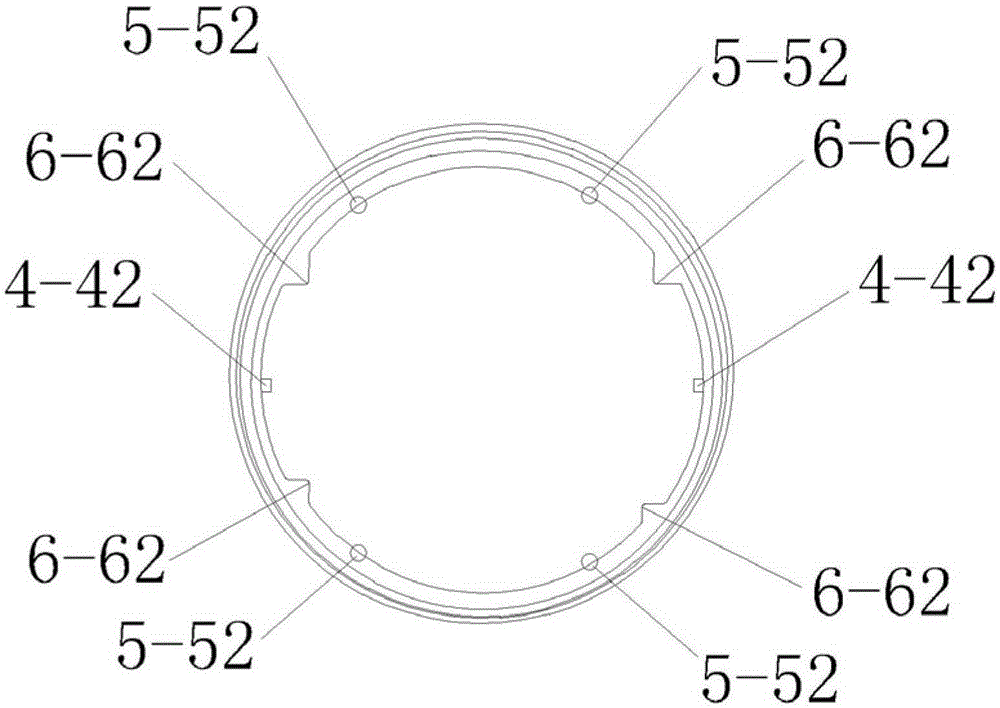

[0027] The embodiment of the present invention provides a fuel filler cap structure, please refer to Figure 1 to Figure 8 , the fuel filler cap structure includes: fuel filler cap outer plate 1, fuel filler box body 2 and fuel filler box hinge assembly 3, the fuel filler cap outer plate 1 is matched with the fuel filler box body 2, and the fuel filler box hinge The assembly 3 connects the fuel filler cap outer panel 1 and the fuel filler box body 2 . That is, the fuel filler of the automobile is arranged on the fuel filler box body 2, and the fuel filler cover outer plate 1 is used to block the fuel filler when it is not in the refueling state. The surface gap and flatness meet the design requirements, and it is beautiful and elegant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com