Cold leveling method for after-welding deformation of gasoline and diesel hydrofining Phi3,000 redistribution plates

A hydrofinishing and cold leveling technology, used in manufacturing tools, welding equipment, arc welding equipment, etc., can solve the problems of lack of suitable processing methods and inconvenience, and achieve high leveling operation efficiency and uniform hitting force. , the effect of easy deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the cold straightening of the post-welding deformation of the gasoline and diesel hydrofining Φ3000 redistribution plate proposed according to the present invention will be combined with the accompanying drawings and preferred embodiments below. The specific implementation, processing method, steps, features and effects thereof of the flat method are as follows in detail.

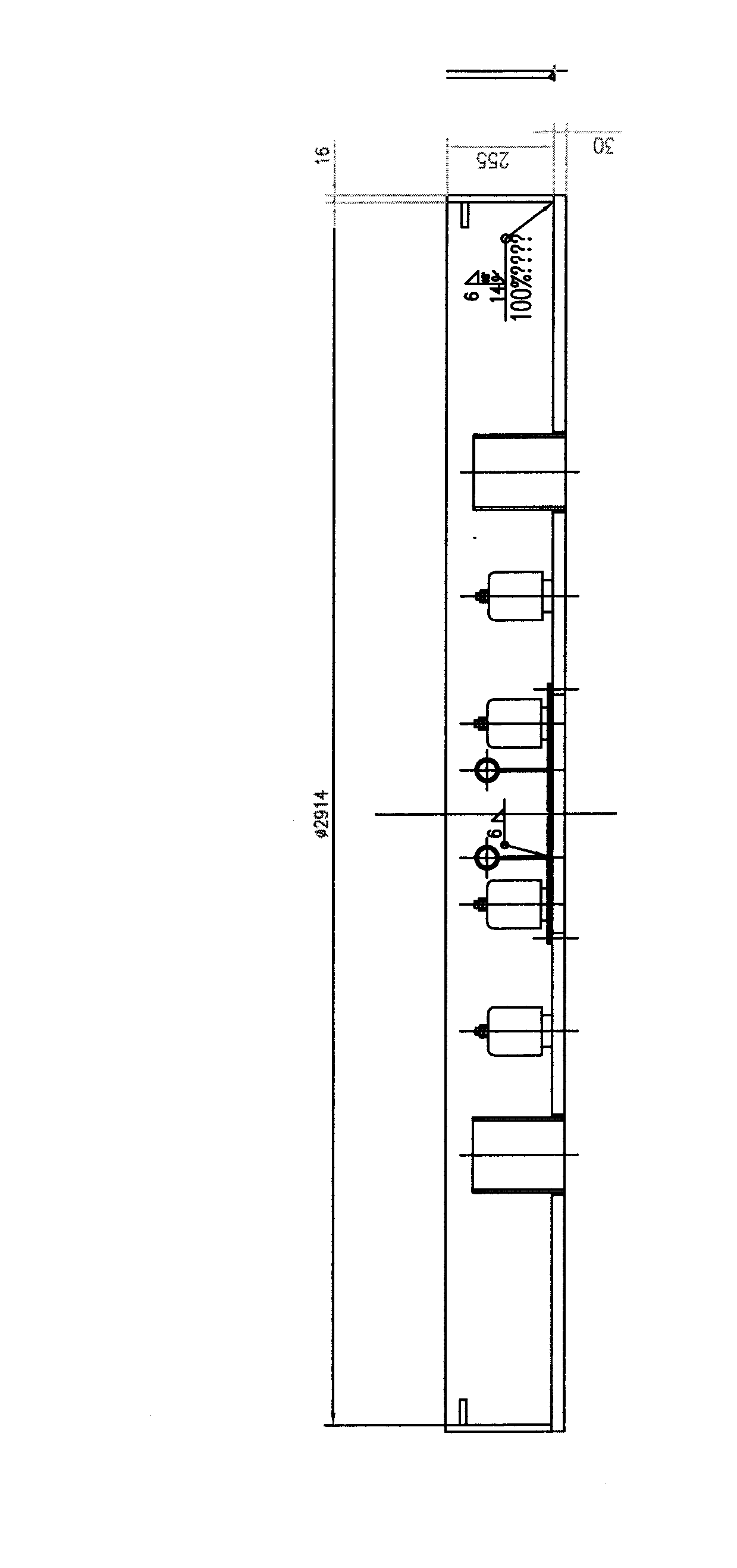

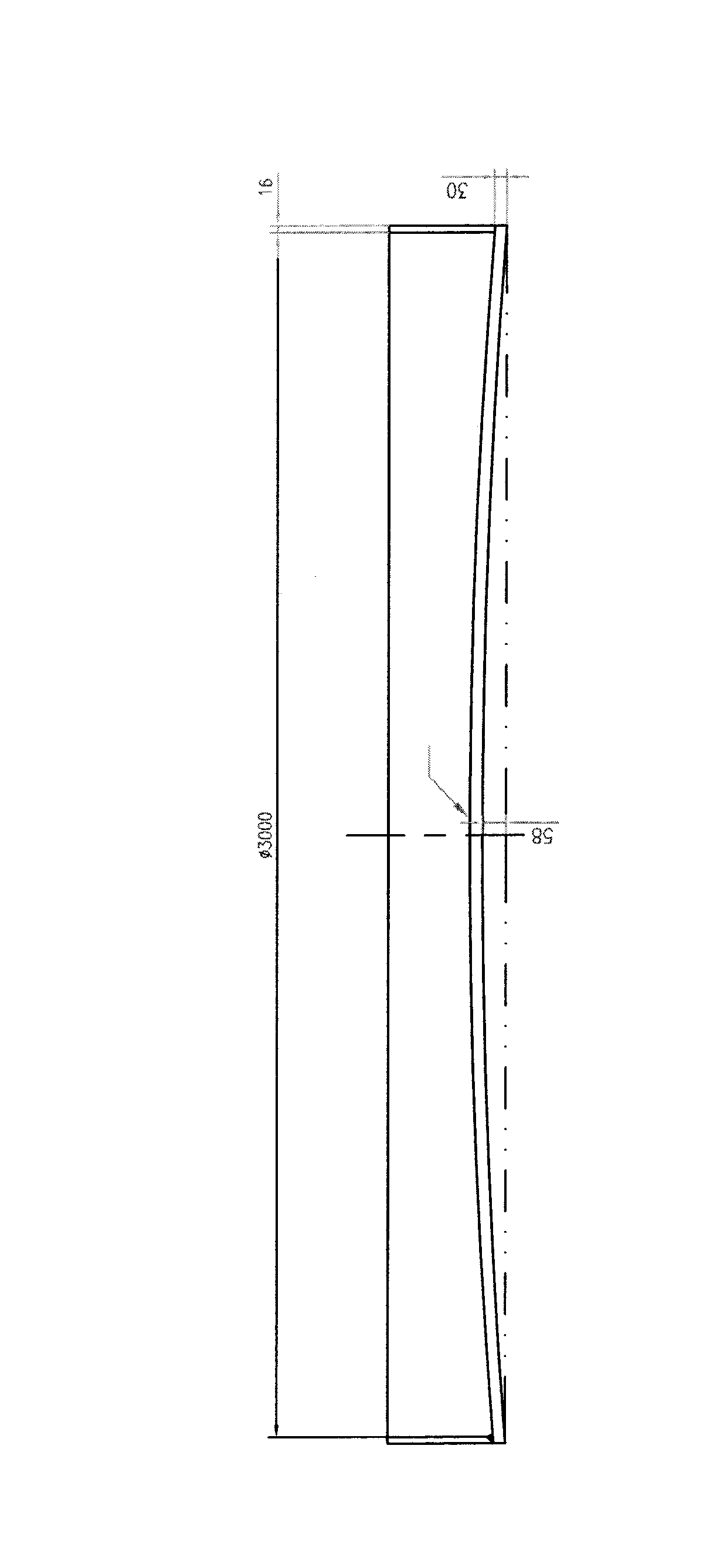

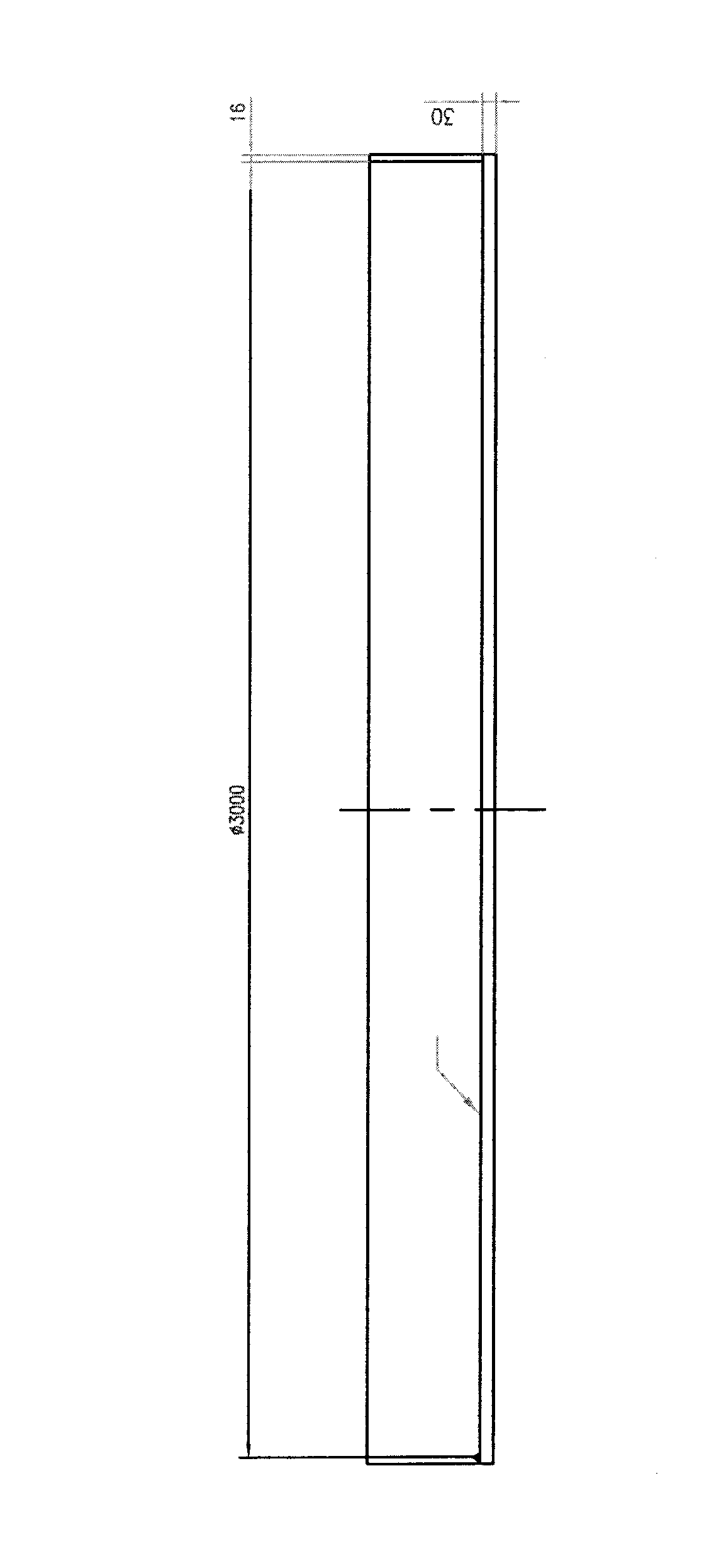

[0021] The present invention guarantees the flatness of the redistribution plate for anti-deformation (please refer to figure 1 ), the following measures were taken:

[0022] 1. The welding material is A132, and it is required to use small current, multi-layer, multi-pass welding as much as possible during welding, and strictly control the temperature between layers to reduce heat input to prevent deformation.

[0023] 2. After the redistribution plate is assembled, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com