Calibration device for processing thin-walled cylindrical parts

A technology of parts processing and thin-walled tubes, which is applied in the field of calibration devices, can solve the problems of inability to process and flanging the side wall holes of tube parts, etc., and achieve the effect of easy operation, easy operation, and avoiding sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the embodiments and the accompanying drawings. as a limitation of the present invention.

[0056] As shown in this application and the claims, unless the context clearly dictates otherwise, the words "a," "an," "an," and / or "the" are not intended to specifically refer to the singular and include the plural.

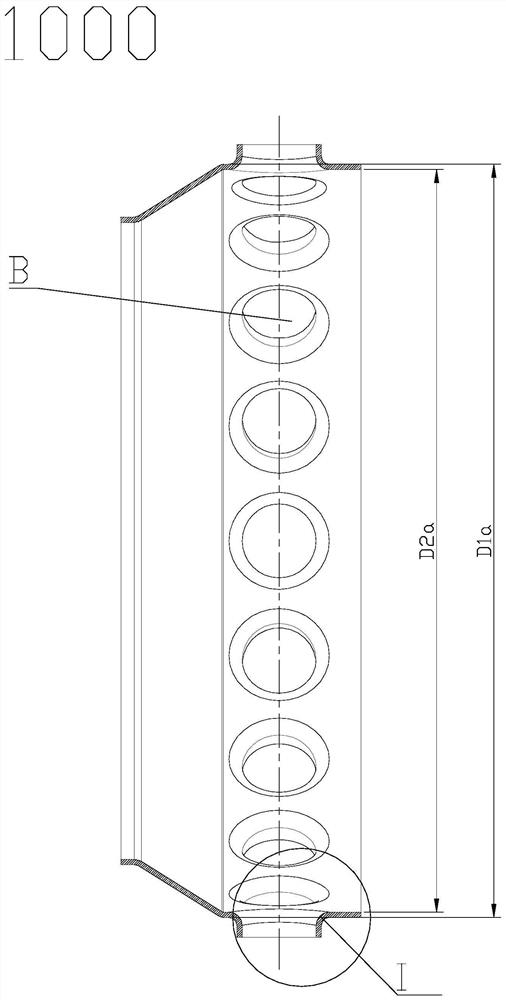

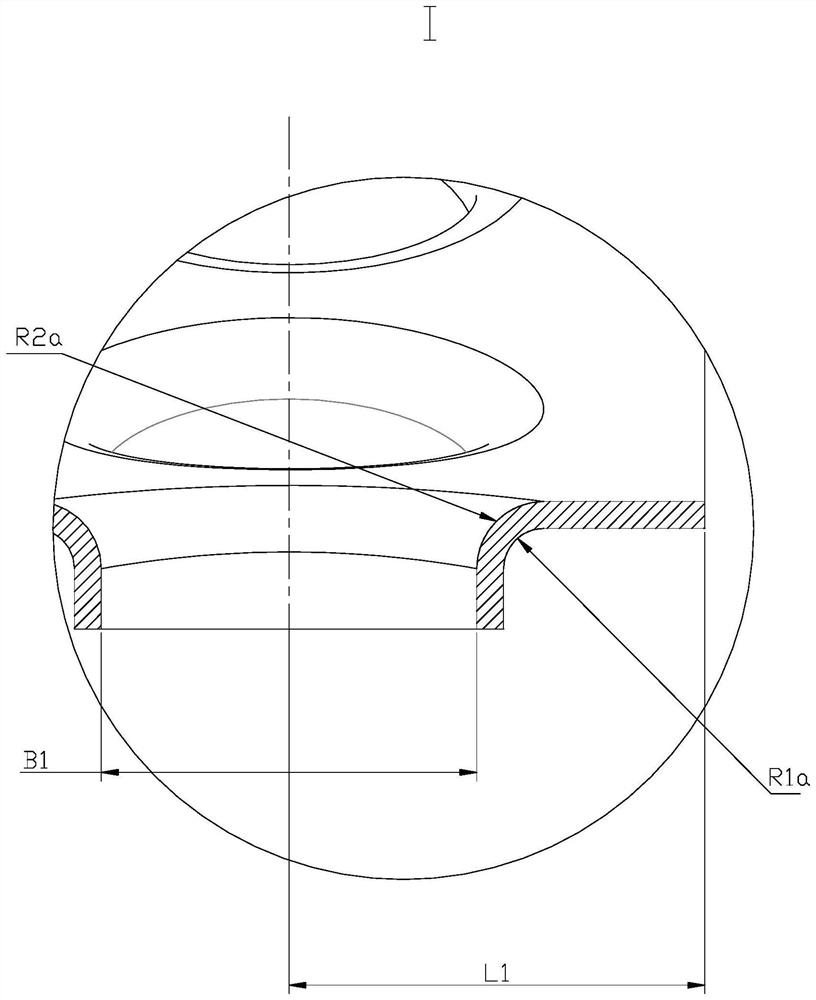

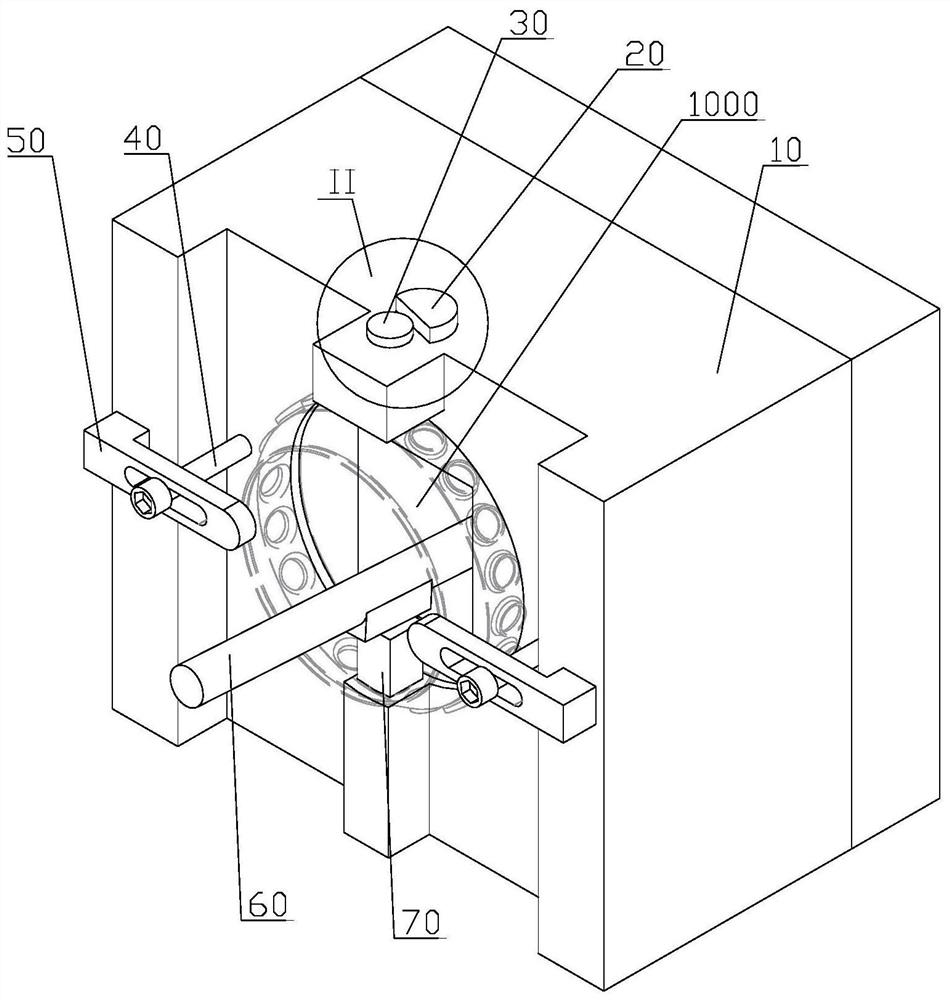

[0057] In some embodiments, as image 3 The calibrating device shown is used for machining and calibrating the flanging holes on the side walls of thin-walled cylindrical parts, for example, for calibrating the flanging convex cylinder B of the part 1000. Parts 1000 such as figure 1 and figure 2 Shown is a cylindrical thin-walled part, and a flanged flange B with outward flange is arranged on the outer ring surface D1a. The dimensions that need to be guaranteed for the flanged barre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com