Roller rubber sheet compacting apparatus

A technology of compaction device and roller glue, which is applied in the direction of lamination device, lamination, layered products, etc., can solve the problems of affecting the quality of rollers and low production efficiency, and achieve improved quality, increased production efficiency, and uniform hitting force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

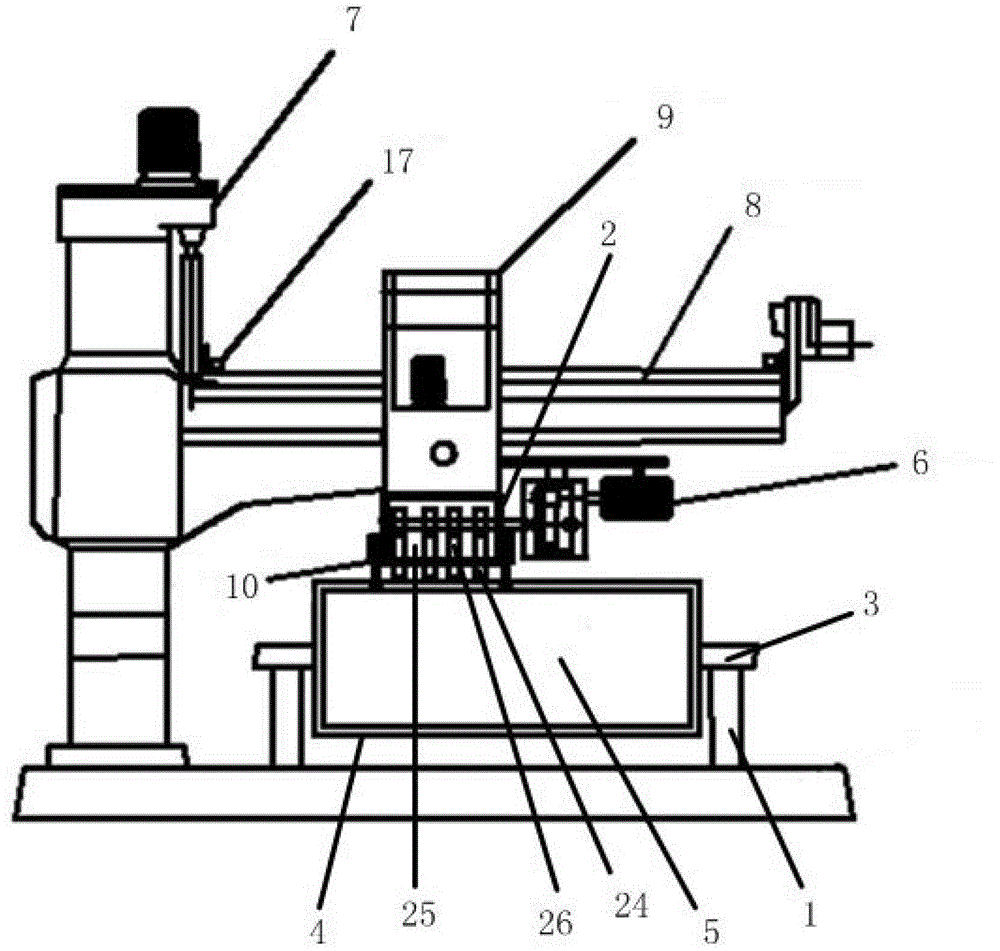

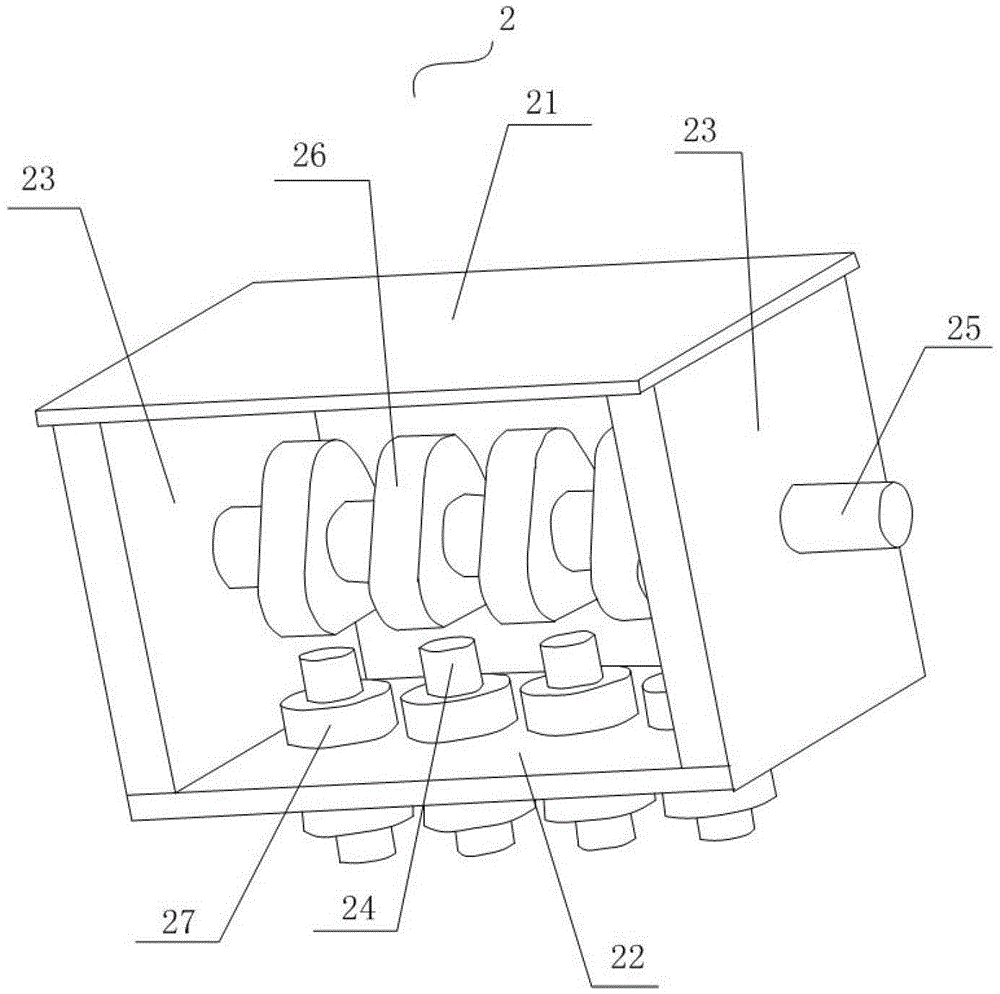

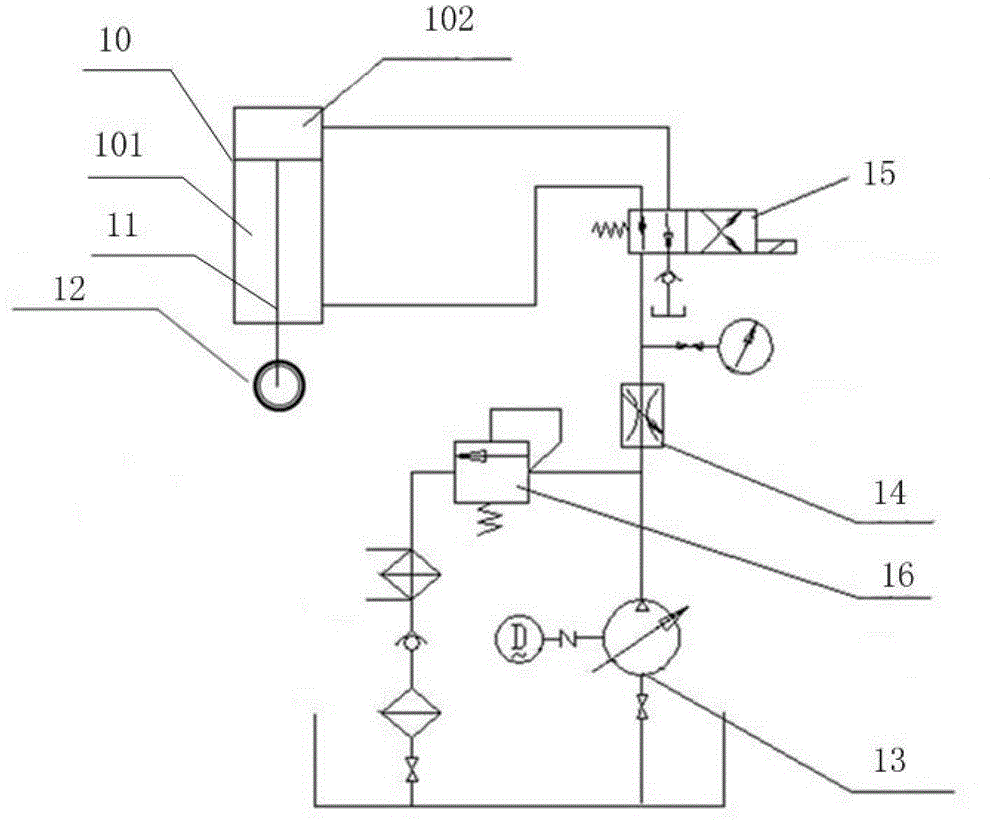

[0028] like figure 1 and figure 2 As shown, the present invention provides a roller rubber sheet compaction device, which includes a bracket 1 and a cam compaction box 2, a rotating shaft 3 is arranged on the bracket 1, and a roller 5 glued with a rubber sheet 4 is sleeved on the rotating shaft 3 The cam compaction box 2 is arranged on the top of the support 1, and the cylinder 5 rotates under the drive of the rotating shaft 3, and the cam compaction box 2 can move along the horizontal direction and the vertical direction parallel to the axial direction of the cylinder 5. The cam compaction box 2 comprises a horizontal top surface 21 , a horizontal bottom surface 22 and two vertical sides 23 . Wherein, the horizontal bottom surface 22 is fixedly pierced with a sleeve 27 and a retractable and movable ejector rod 24 , the ejector rod 24 is covered with a return spring, and the ejector rod 24 is disposed in the sleeve 27 . A groove can be provided in the sleeve 27 for accommod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com