Novel electric control cabinet

An electrical control cabinet, a new type of technology, applied in the direction of electrical equipment shell/cabinet/drawer, electrical components, cooling/ventilation/heating renovation, etc. problems, to achieve the effect of saving energy consumption, reducing working environment requirements, and convenient application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

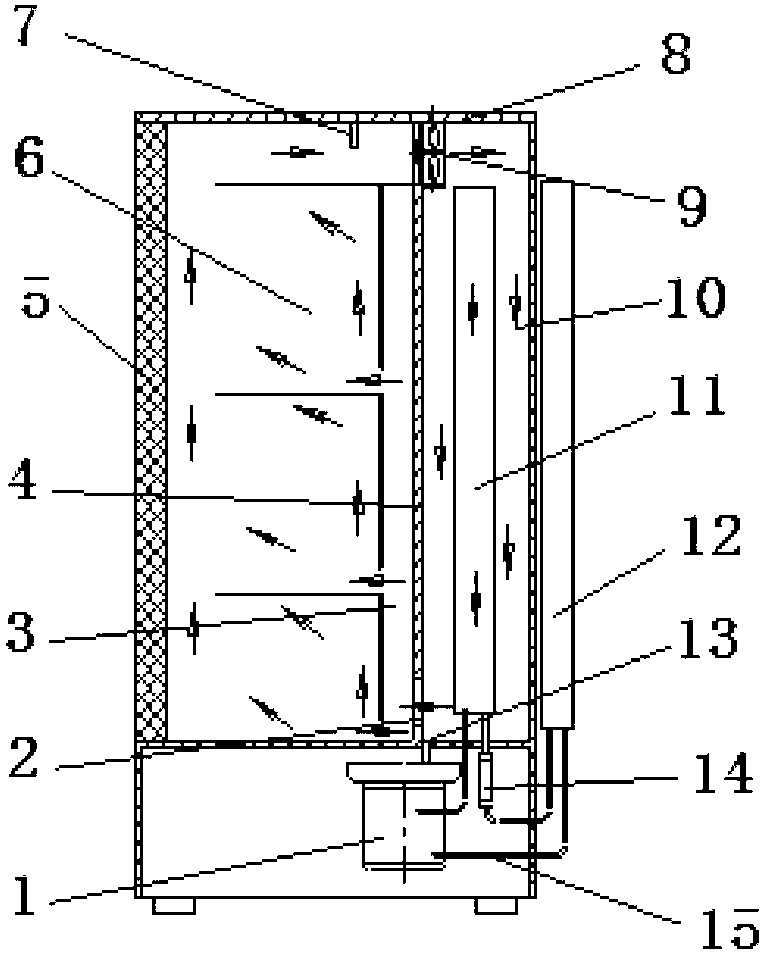

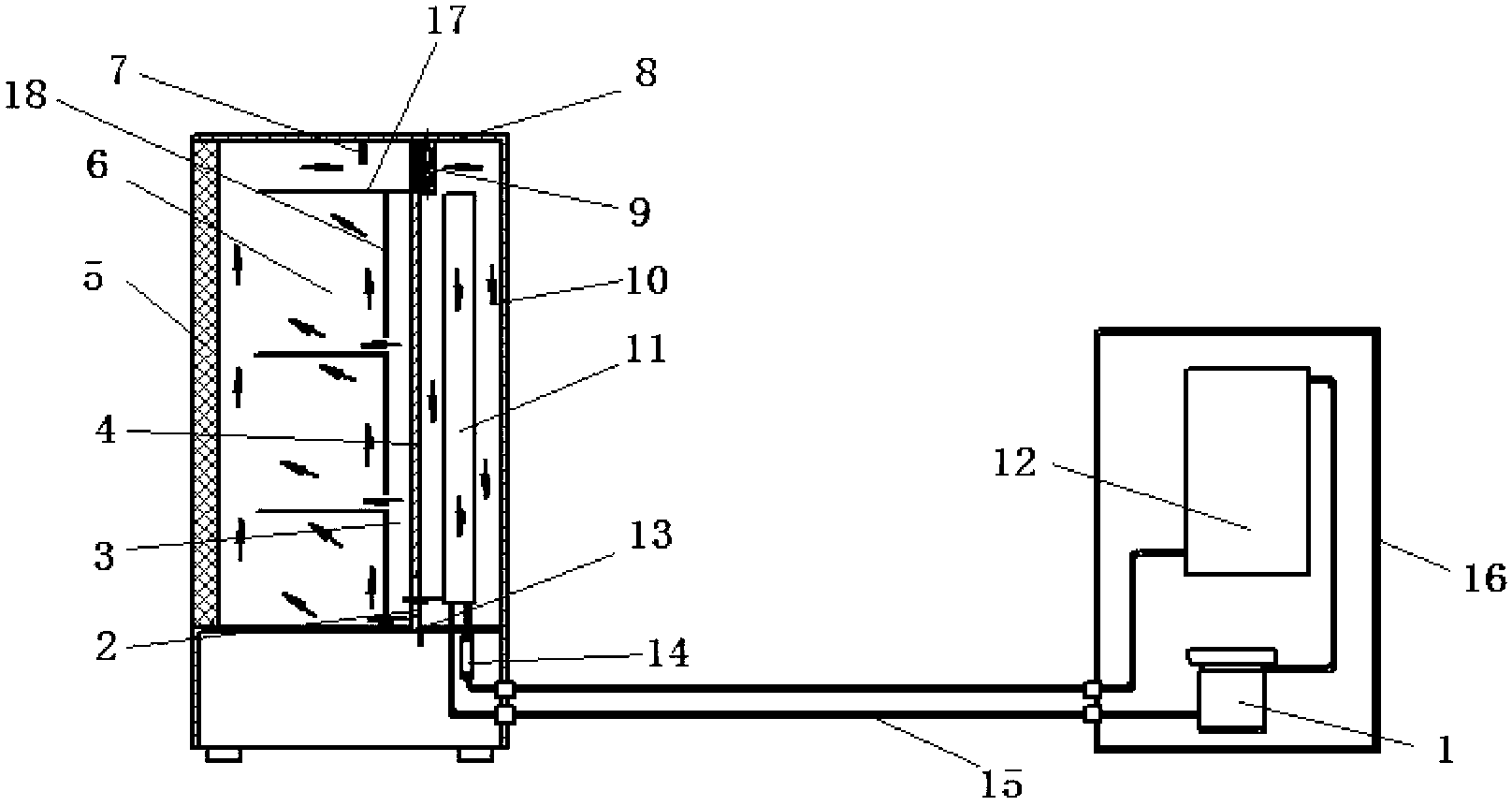

[0020] refer to figure 1 with figure 2 , a new type of electrical control cabinet, including a cabinet door 5 and a cabinet body 8, the cabinet body 8 has a closed structure, and a partition 4 is vertically provided in the cabinet body 8, and the partition board 4 separates the cabinet body 8 The internal space is divided into the equipment working area 6 and the medium cooling and drying area 10; the upper end of the partition 4 is equipped with an internal circulation fan 9, and the air flow direction flows from the equipment working area 6 to the medium cooling and drying area 10, and the bottom of the partition 4 A cold air inlet 2 is provided; a heat dissipation assembly 12 is provided on the outer wall of the cabinet body 8 close to the side of the medium cooling and drying area 10, and a heat absorbing assembly 11 is arranged in the medium cooling and drying area 10, and the heat absorbing assembly 11 is connected to the compressor 1 through the connecting pipeline 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com