Flow distribution device for pressurized-water nuclear reactor

A flow distribution device and nuclear reactor technology, applied in the field of pressurized water nuclear reactor flow distribution device, can solve the problems of difficult maintenance, high resistance coefficient, complex structure and installation, etc., and achieve the effect of easy maintenance and inspection, and reduce vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

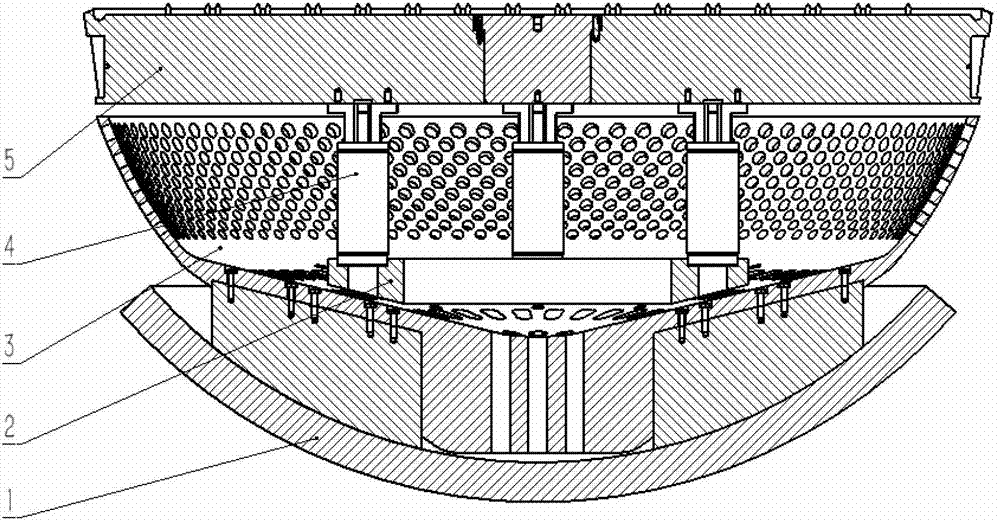

[0019] A pressurized water nuclear reactor flow distribution device according to the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

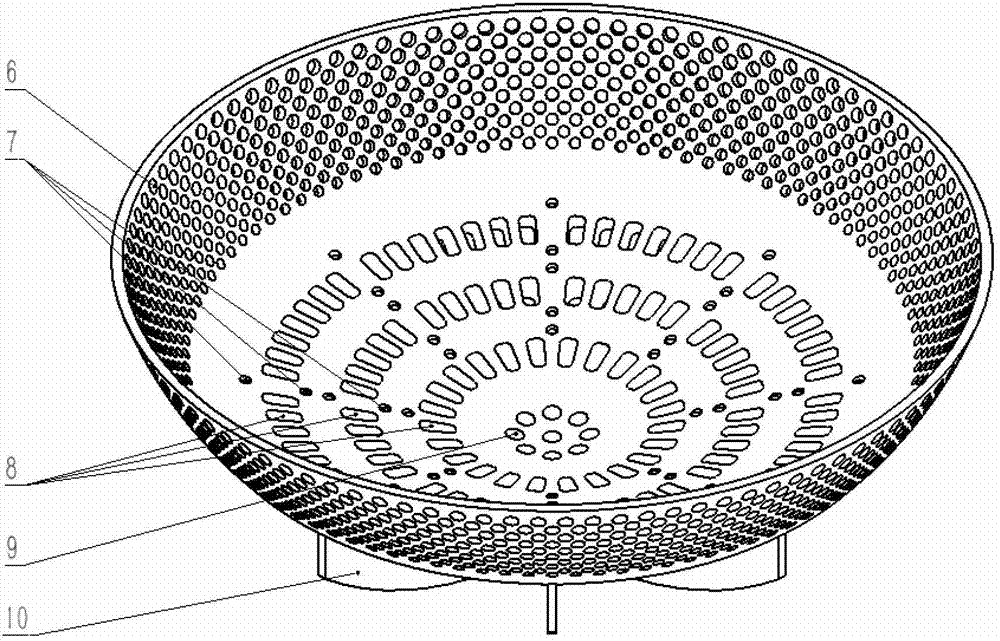

[0020] Such as figure 1 As shown, a flow distribution device for a pressurized water nuclear reactor according to the present invention has a spherical bowl-shaped mesh structure, and eight support ribs 10 are fixed below the bottom of the distribution device, and the eight support ribs 10 are fixed by connecting screws 7 Connects below the bottom of the dispensing unit.

[0021] 10 rows of circular openings are arranged rotationally symmetrically on the middle and upper part of the circumferential side wall of the bowl of the distribution device, each row of circular openings includes 100 circumferentially evenly distributed circular holes 6, and the diameters of each row of openings are different, from top to bottom The order is 66mm, 64mm, 62mm, 60mm, 58mm, 56mm, 54mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com