Rotating arm type axle box force measuring device and method thereof

A force-measuring device and arm-type technology, which is applied in the field of rail transit, can solve problems such as harsh limitations, and achieve the effect of reducing stress damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

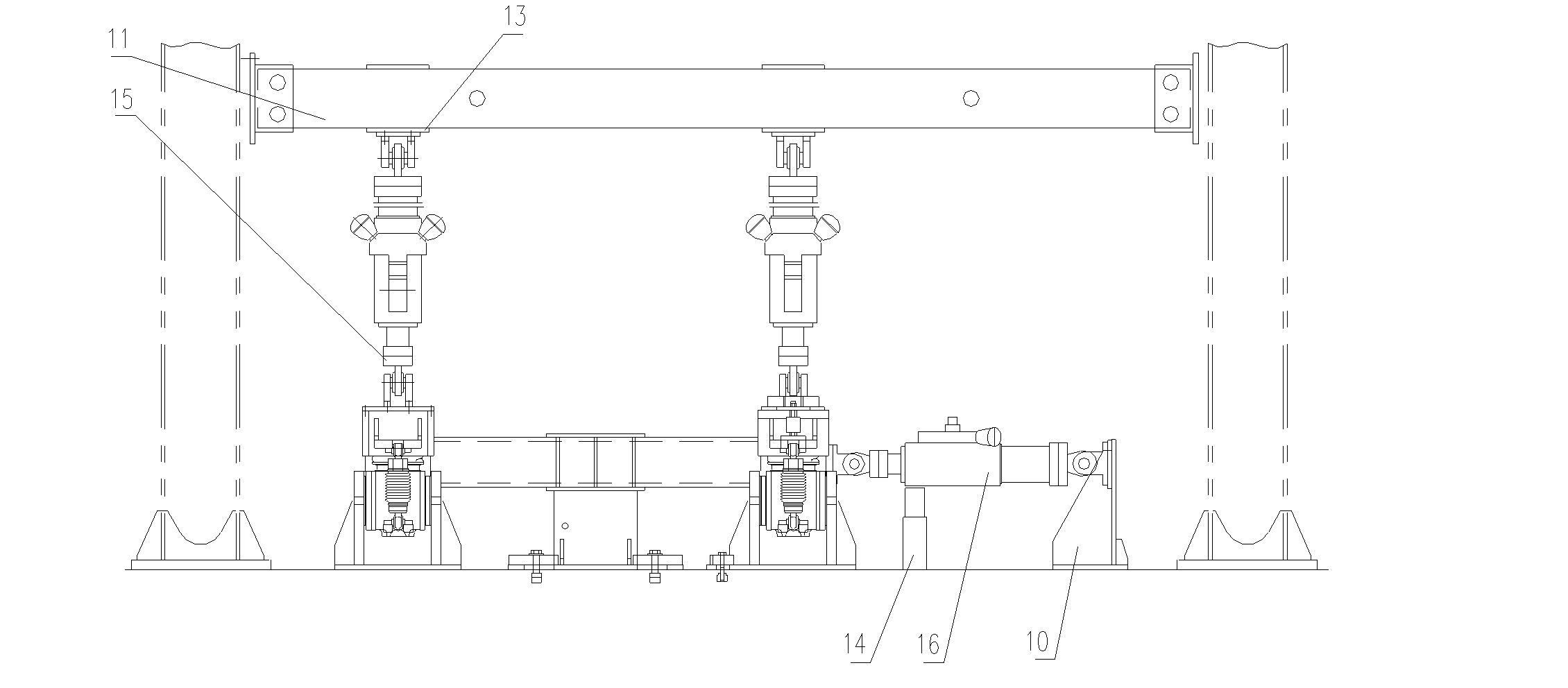

[0049] Example 1, such as Figure 1 to Figure 3 As shown, the force measuring device used to realize the method of measuring the force of the pivoting arm axle box mainly includes a loading beam 11 and a simulation frame 6, and four pivoting arm axle boxes 4 are installed according to the actual use positions.

[0050] Among them, a pair of vertical actuators 15 are connected vertically between the simulation frame 6 and the loading beam 11, that is, the bottom ends of the two vertical actuators 15 are respectively connected to the air spring seats 24 on both sides of the simulation frame 6. , the top of the vertical cylinder 15 is connected to the loading beam 11 through the cylinder hanger 13;

[0051]Connect the lateral actuator 16 to the side beam 25, and load the actuator elastic support 14 at the bottom of the lateral actuator 16;

[0052] Connect the longitudinal cylinder 17 to the center pin 26, and load the cylinder elastic support 14 at the bottom of the longitudina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com