Pipe material length automatic measurement devices and measurement method thereof

A technology of automatic measurement and measurement method, applied in the direction of measuring devices, optical devices, instruments, etc., to achieve the effect of simple process, novel structure, and guaranteed online length measurement time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

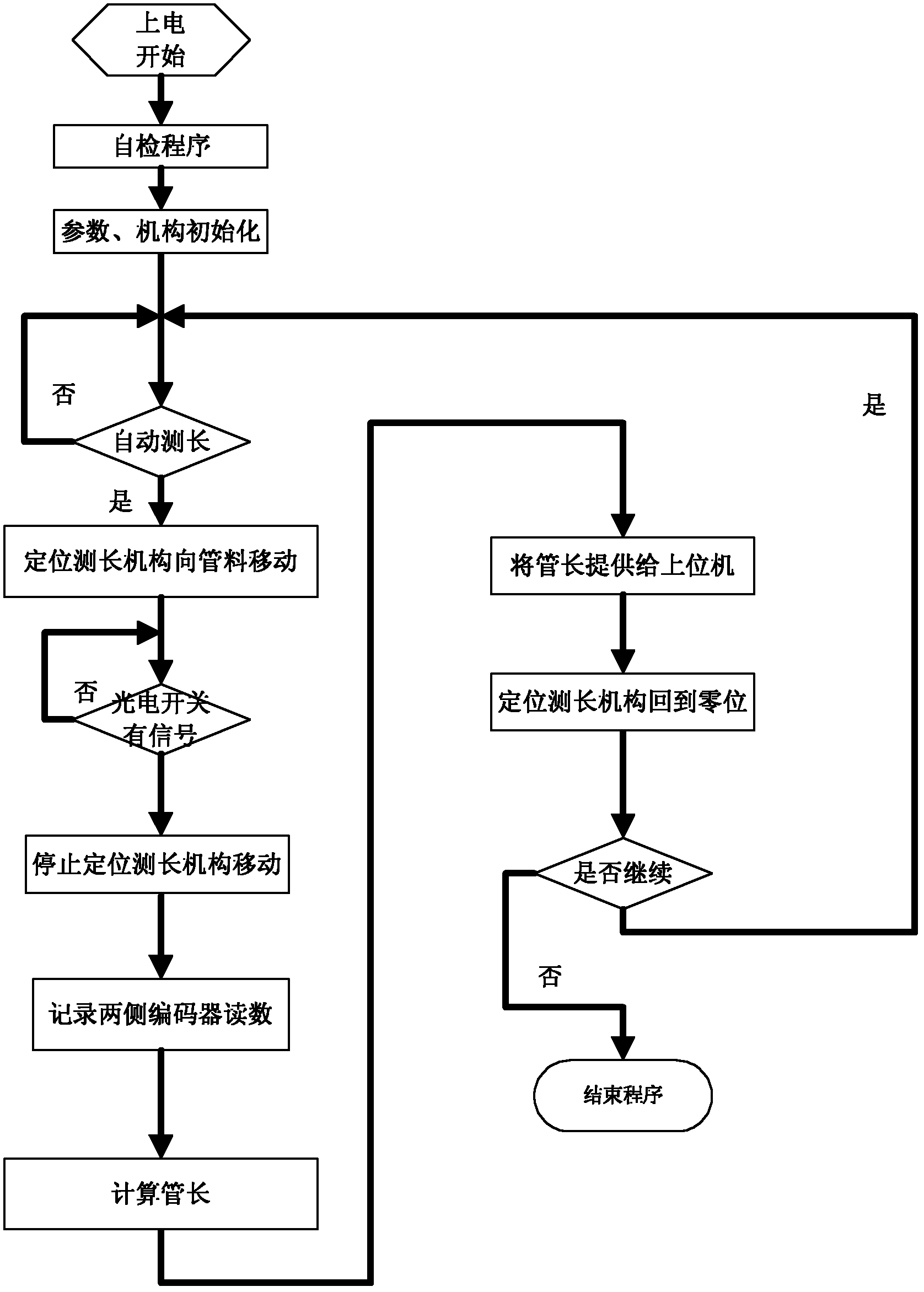

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

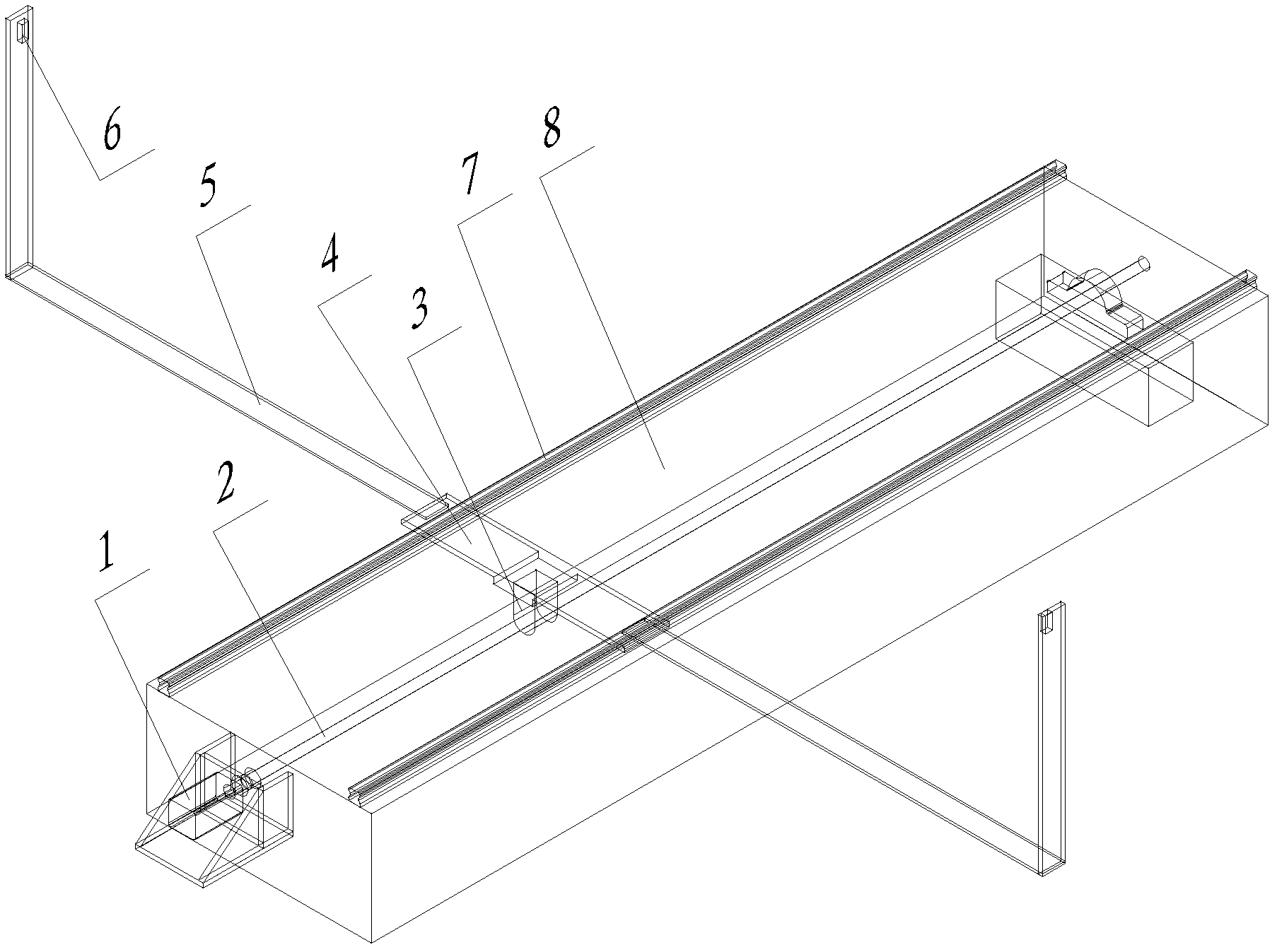

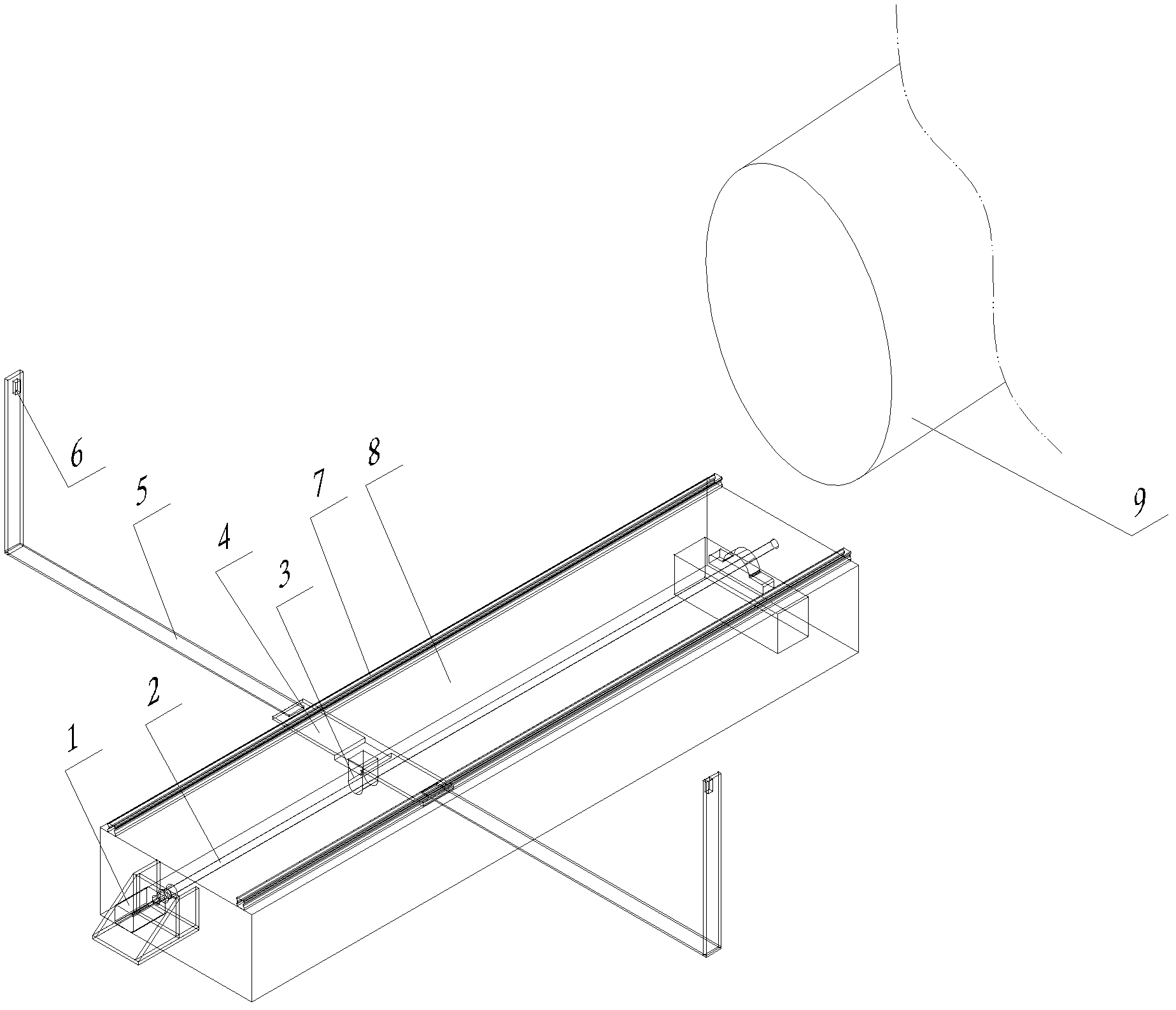

[0023] Such as figure 1 , figure 2 As shown, the automatic measuring device of the present invention includes a positioning detection mechanism, a driving mechanism and a base 8, wherein two mutually parallel linear guide rails 7 are installed on the base 8, and the positioning detection mechanism is installed on the linear guide rails 7 of the base 8, and the The driving mechanism is installed on the base 8, the positioning detection mechanism is connected with the driving mechanism, and is driven to reciprocate horizontally along the linear guide rail 7 by the driving mechanism.

[0024] The driving mechanism includes a servo motor 1, a ball screw 2 and a screw nut 3, wherein the two ends of the ball screw 2 are respectively connected to the base 8 in rotation, and the end of the ball screw 2 away from the tube material 9 to be tested passes through the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com