Leakage-proof end cover of rotating shaft

A rotating shaft, leak-proof technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of poor stability, low efficiency of leak-proof end cover, etc., to achieve strong stability, high economic added value, beautiful structure Generous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

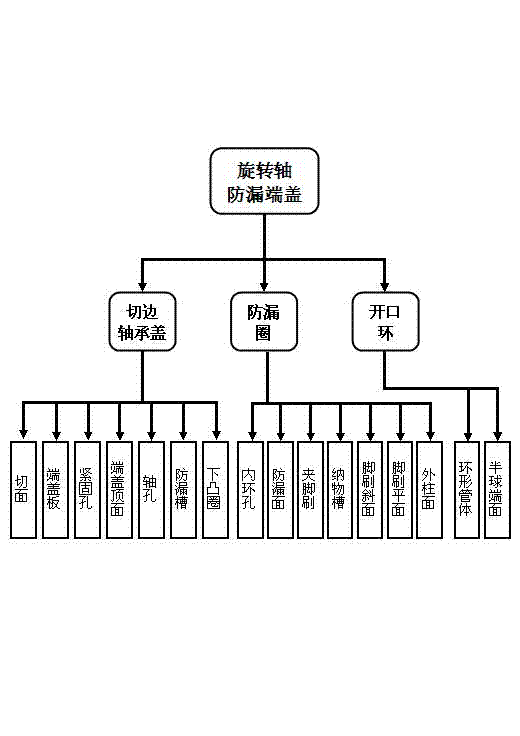

[0041] As a technical proposal for product manufacturing, the present invention can implement the proposal through the organic combination of corresponding parts. The product organization structure of an embodiment of the present invention is as follows: figure 1 shown.

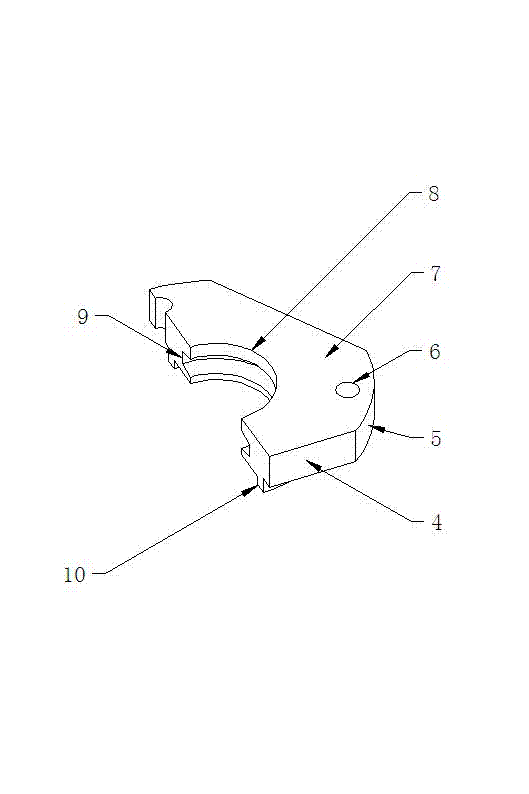

[0042] figure 1 Among them, the product is composed of three parts: trimming bearing cap, anti-leakage ring and split ring. Among them, the structure of trimming bearing cap parts includes cutting surface, end cover plate, fastening hole, end cap top surface, shaft hole and anti-leakage groove 1. Seven components of the lower convex ring. The leak-proof ring part structure includes seven components: the inner ring hole, the leak-proof surface, the pinch brush, the storage tank, the foot brush slope, the foot brush plane, and the outer cylinder. The split ring part The structure includes two parts: the annular pipe body and the hemispherical end face.

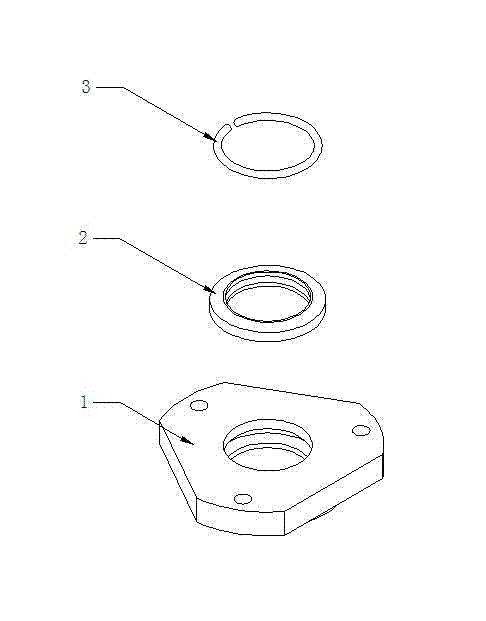

[0043] Embodiment, each part form such as figure 2 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com