Gas suction structure of compressor

A compressor and cylinder technology, applied in the field of compressor suction structure, can solve problems such as turbulent flow, reduction of effective volume of cylinder, insufficient heating capacity of compressor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

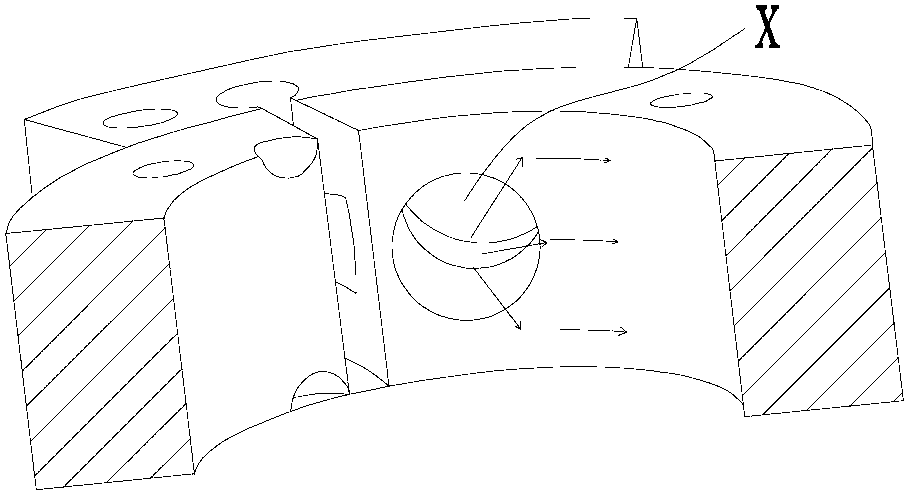

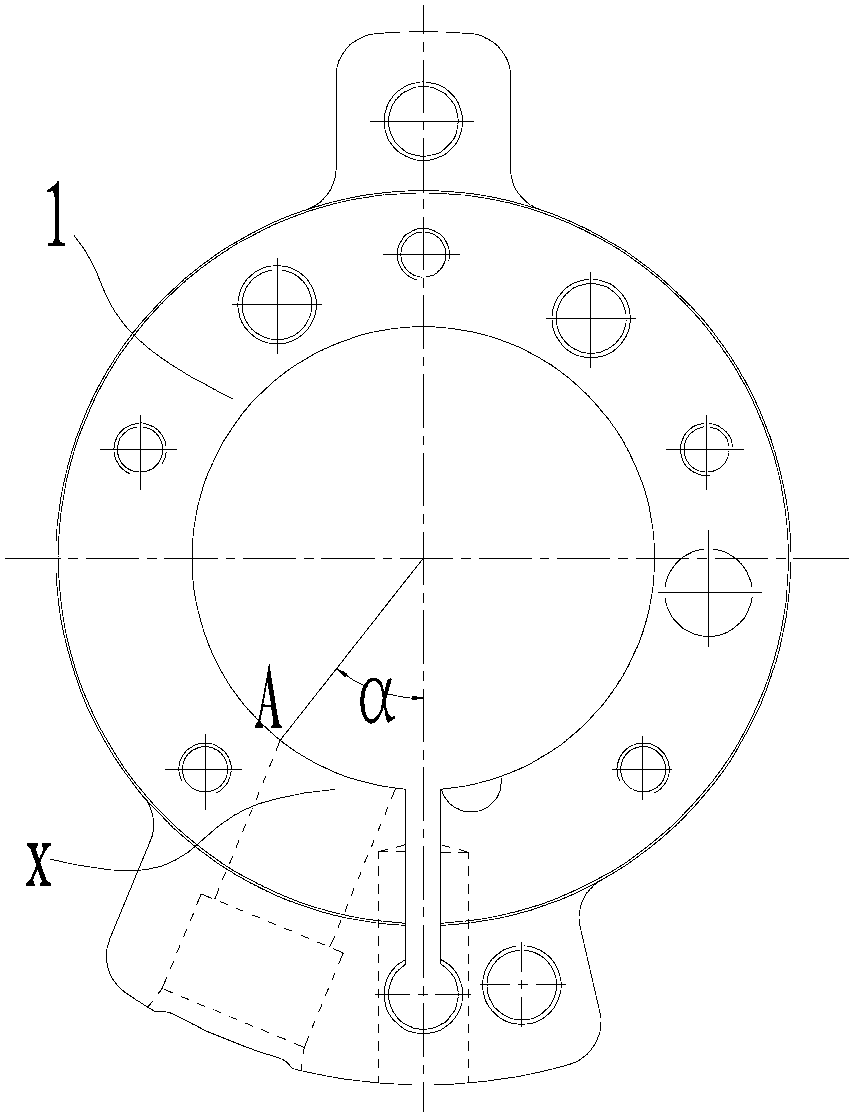

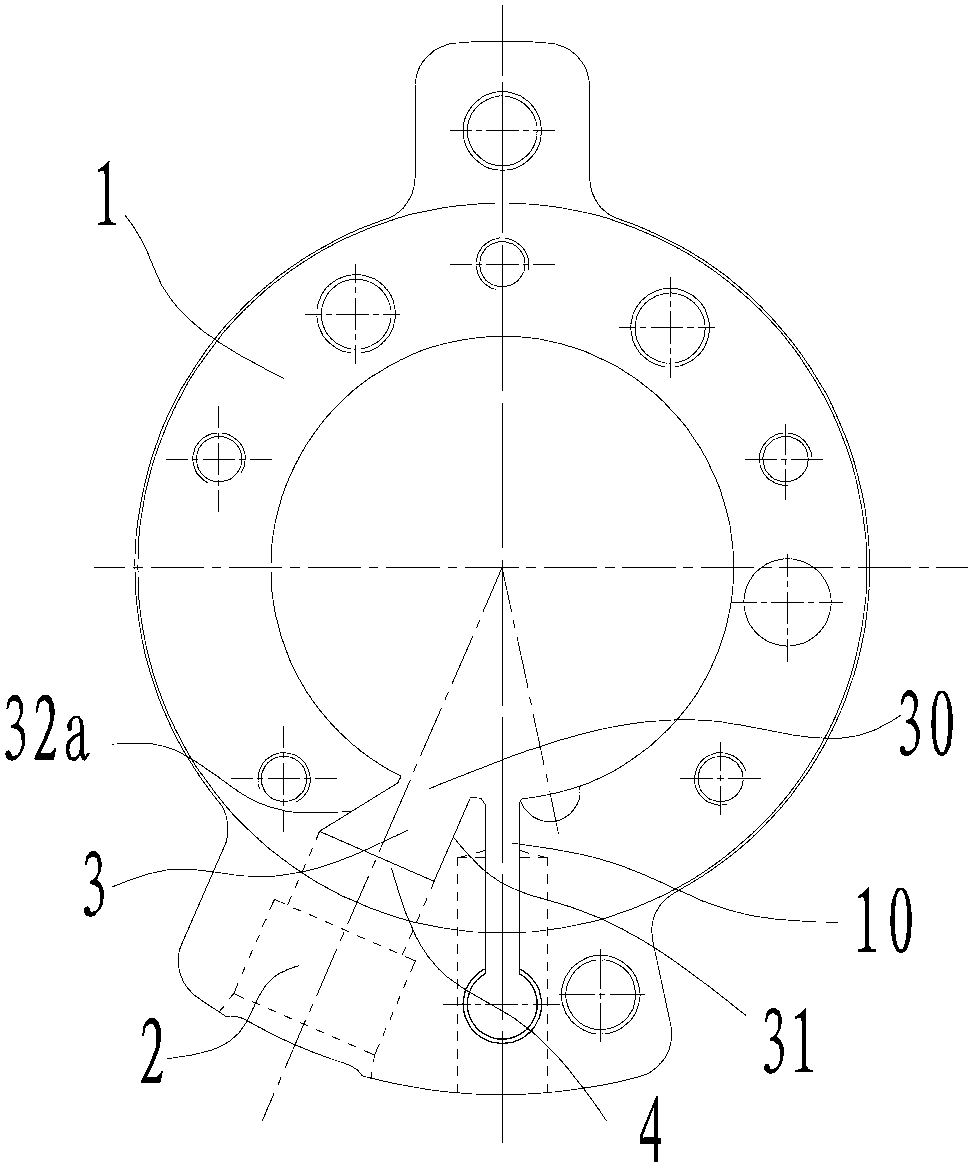

[0027] A suction structure of a compressor, such as image 3 As shown, it includes the air intake channel 2 opened radially on the cylinder 1, and also includes: a suction port formed on the inner wall side of the cylinder 1 along the axial direction of the cylinder 1, which passes through the two ends of the cylinder and communicates with the air intake channel 2 and is vertically arranged. Channel 3, the air inlet of the suction channel 3 on the inner wall of the cylinder is a rectangular air inlet 30 formed along the axial direction of the cylinder through the two ends of the cylinder, and the rectangular air inlet 30 is close to the slide slot 10 of the cylinder 1 Set, the rectangular air inlet 30 is a rectangular hole with a narrow horizontal direction and a long vertical direction; the diameter of the connecting port 4 of the suction channel 3 and the air intake channel 2 to the rectangular air inlet 30 gradually becomes smaller, and the suction The channel 3 near the si...

Embodiment 2

[0029] Such as Figure 4 to Figure 6 As shown, the difference from Embodiment 1 is that the side of the suction channel 3 away from the slide groove 10 forms an obtuse-angled vertical channel surface 32b that passes through the two ends of the cylinder 1 and consists of two connecting sections. A section of the passage surface 32b is flush with the inner edge of the air intake passage and is arranged parallel to the radial centerline of the air intake passage. Tilt setting.

Embodiment 3

[0031] Such as Figure 7 As shown, the difference from Embodiment 1 is that the suction passage 3 is away from the sliding vane groove 10 and forms an arc-shaped vertical passage surface 32c that passes through both ends of the cylinder 1 and smoothly connects with the rectangular air inlet 30 in an arc shape. This facilitates the smooth transition of the gas flowing out from the air intake passage to the rectangular air intake 30 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com