A kind of fog surface oil-resistant elastomer cable material and preparation method thereof

A technology of elastomer and cable material, which is applied in the field of matte oil-resistant elastomer cable material and its preparation, can solve the problems that the comprehensive performance of matte cables is difficult to guarantee, neglecting oil resistance, etc., so as to improve the matte effect, oil resistance and good mechanical properties. , the effect of good comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

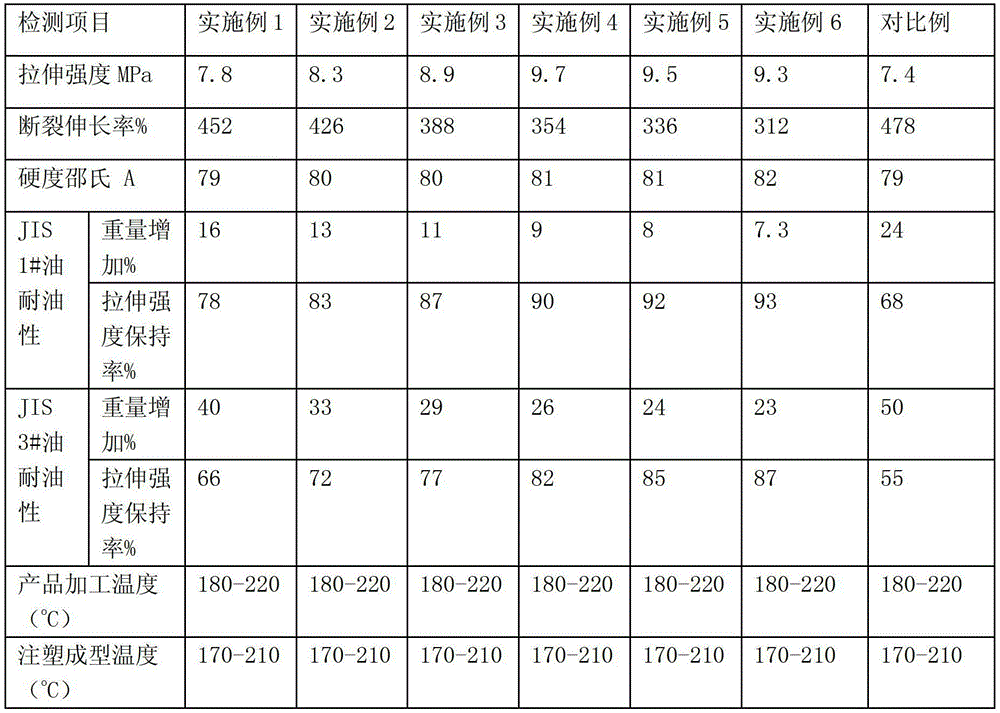

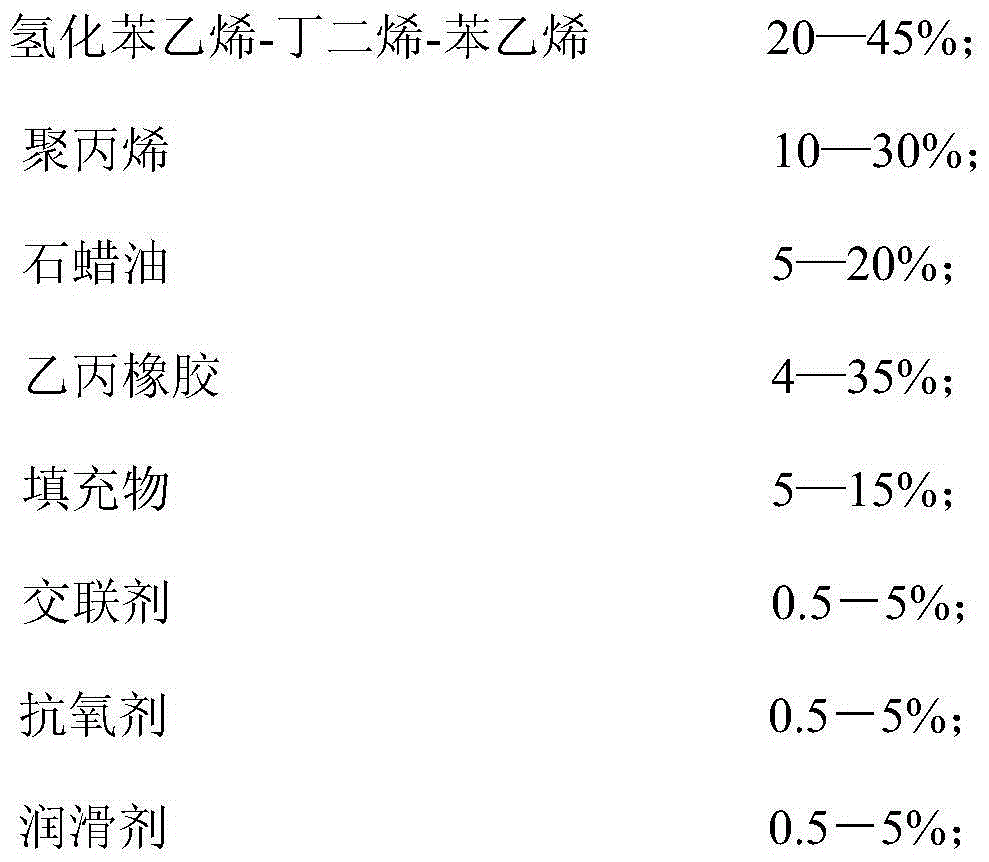

Embodiment 1

[0036] Weigh each component according to the following weight percentage: 40% hydrogenated styrene-butadiene-styrene, 20% polypropylene, 20% paraffin oil, 4% ethylene-propylene rubber, 10% filler, 4% crosslinking agent, Antioxidant 1%, lubricant 1%; put the above materials in a mixing tank and pre-mix for 10 minutes, and the stirring speed is controlled at 500 rpm; then put the mixed materials in a twin-screw extruder for plasticization , Granulation, the processing temperature is controlled at 180-190 °C; the plasticized rubber grains are drawn through the machine head, soaked in water, cooled, air-dried, pelletized and packaged.

[0037] Among them, hydrogenated styrene-butadiene-styrene is a pure resin with a weight average molecular weight of 50,000 to 100,000; polypropylene has a melt flow rate (test condition of 230°C / 2.16KG) of 1g / 10 minutes to 4g / 10 Minute polypropylene resin; paraffin oil is paraffin oil with a kinematic viscosity (at a temperature of 40°C) of 16-400m...

Embodiment 2

[0039] Weigh each component according to the following weight percentage: 36% hydrogenated styrene-butadiene-styrene, 20% polypropylene, 20% paraffin oil, 8% ethylene-propylene rubber, 10% filler, 4% crosslinking agent, Antioxidant 1%, lubricant 1%; put the above materials in a mixing tank and pre-mix for 20 minutes, and the stirring speed is controlled at 300 rpm; then put the mixed materials in a twin-screw extruder for plasticization , granulation, the processing temperature is controlled at 190-200 ℃; the plasticized rubber granules are drawn through the machine head, soaked in water, cooled, air-dried, pelletized and packaged.

[0040] Among them, hydrogenated styrene-butadiene-styrene is a pure resin with a weight average molecular weight of 50,000 to 100,000; polypropylene has a melt flow rate (test condition of 230°C / 2.16KG) of 1g / 10 minutes to 4g / 10 Minute polypropylene resin; paraffin oil is paraffin oil with a kinematic viscosity (at a temperature of 40°C) of 16-400...

Embodiment 3

[0042] Weigh each component according to the following weight percentage: hydrogenated styrene-butadiene-styrene 32%, polypropylene 20%, paraffin oil 20%, ethylene-propylene rubber 12%, filler 10%, crosslinking agent 4%, Antioxidant 1%, lubricant 1%; put the above materials in a mixing tank and pre-mix for 30 minutes, and the stirring speed is controlled at 200 rpm; then put the mixed materials in a twin-screw extruder for plasticization , Granulation, the processing temperature is controlled at 200-210 °C; the plasticized rubber grains are drawn through the machine head, soaked in water, cooled, air-dried, pelletized and packaged.

[0043] Among them, hydrogenated styrene-butadiene-styrene is a pure resin with a weight average molecular weight of 50,000 to 100,000; polypropylene has a melt flow rate (test condition of 230°C / 2.16KG) of 1g / 10 minutes to 4g / 10 Minute polypropylene resin; paraffin oil is paraffin oil with a kinematic viscosity (at a temperature of 40°C) of 16-400...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com