Hydrolysis graft strengthened anionic carboxymethyl cellulose flocculating agent and preparation method thereof

A carboxymethyl cellulose, anion technology, applied in the direction of flocculation / sedimentation water / sewage treatment, etc., can solve the problems of low molecular weight, sensitive flocculation effect, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

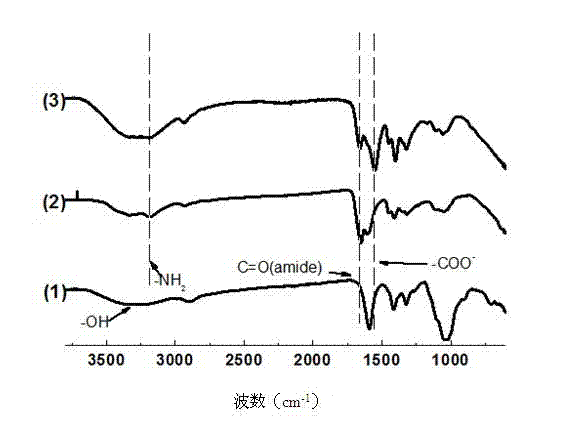

[0034]Dissolve carboxymethyl cellulose (the degree of anionic substitution is about 80%, and the weight average molecular weight is about 150,000) in pure water to prepare a 0.5% solution of carboxymethyl cellulose. After the solution is uniform, add ammonium persulfate as a trigger agent (the amount added is 2% of the molar number of carboxymethyl cellulose units), then add acrylamide (mass ratio to carboxymethyl cellulose: 5:1), react at 45°C for 3 hours, and then use acetone as a precipitate agent, precipitate and separate the product to obtain grafted carboxymethyl cellulose. Disperse grafted carboxymethyl cellulose in a mixed solvent of water and ethanol (the mass ratio of water to ethanol is 1:6, and the mass percentage of grafted carboxymethyl cellulose in the mixed solvent is 1%), adding Sodium hydroxide (sodium hydroxide accounts for 2% by mass of the mixed solvent), reacted at 55°C for 3 hours, filtered and dried after the reaction, and prepared a hydrolyzed grafted ...

Embodiment 2

[0036] Dissolve carboxymethyl cellulose (anion substitution degree is about 90%, weight average molecular weight is about 250,000) in pure water to prepare a 0.1% solution of carboxymethyl cellulose. After the solution is uniform, add ammonium persulfate as a trigger agent (the amount added is 3% of the molar number of carboxymethyl cellulose units), then add acrylamide (mass ratio to carboxymethyl cellulose: 2:1), react at 55°C for 2 hours, and then use acetone as a precipitate agent, precipitate and separate the product to obtain grafted carboxymethyl cellulose. Disperse grafted carboxymethyl cellulose in a mixed solvent of water and ethanol (the mass ratio of water to ethanol is 1:2, and the mass percentage of grafted carboxymethyl cellulose in the mixed solvent is 10%), adding Sodium hydroxide (sodium hydroxide accounts for 8% by mass of the mixed solvent), reacted at 60°C for 0.1 hour, filtered and dried after the reaction, and prepared a hydrolyzed grafted enhanced anion...

Embodiment 3

[0038] Dissolve carboxymethyl cellulose (anion substitution degree is about 85%, weight average molecular weight is about 400,000) in pure water to prepare a 3% carboxymethyl cellulose solution. After the solution is uniform, add potassium persulfate as a trigger agent (addition amount is 1% of the molar number of carboxymethyl cellulose units), then add acrylamide (mass ratio to carboxymethyl cellulose: 6:1), react at 50°C for 2 hours, and then use ethanol as a precipitate agent, precipitate and separate the product to obtain grafted carboxymethyl cellulose. Disperse grafted carboxymethyl cellulose in a mixed solvent of water and ethanol (the mass ratio of water to ethanol is 1:10, and the mass percentage of grafted carboxymethyl cellulose in the mixed solvent is 5%), adding Sodium hydroxide (sodium hydroxide accounted for 5% by mass of the mixed solvent), reacted at 35°C for 5 hours, filtered and dried after the reaction, and prepared a hydrolyzed grafted enhanced anionic ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com