Gold spot temmoku glaze and preparation technology thereof

A technology for the preparation process of Jinban Tianmu glaze and its preparation process, which can solve the problems of inability to prepare Tianmu glaze, etc., and achieve the effects of preparation efficiency, energy saving and environmental protection, good decorative effect, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

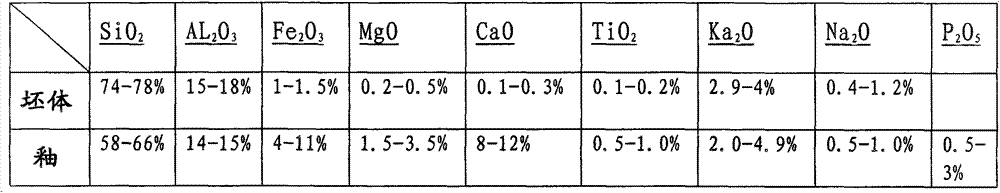

[0016] The raw material composition formula of Jinban Tianmu glaze, Jinban Tianmu glaze enamel contains the following raw material components in terms of mass fraction: 40% feldspar, 4% kaolin, 6% high iron ore soil, 25% quartz, 2% titanium dioxide, Lin'an glazed soil 8%, limestone 7%, talc 8%; Jinban Tianmu glaze body contains the following raw material components according to mass fraction: feldspar 12%, purple gold soil 23%, porcelain stone 38%, quartz 22%, high Iron ore soil 5%.

[0017] In the process of selecting raw materials, it is necessary to conduct on-site inspections, collect raw materials, conduct physical and chemical analysis on raw materials, and start processing raw materials after screening and elutriation.

[0018] Processing of Jinban Tianmu glaze enamel and body raw materials, raw material processing includes grinding and screening, proportioning, dehydration, stale, manual molding, trimming and drying processes. In the grinding and screening process, th...

Embodiment 2

[0020] The raw material composition formula of Jinban Tianmu glaze, Jinban Tianmu glaze enamel contains the following raw material components according to the mass fraction: 46% feldspar, 5% kaolin, 8% ferric ore, 27% quartz, 1% titanium dioxide, 5% Lin'an glazed soil, 5% limestone, 3% talc; Jinban Tianmu glaze body contains the following raw material components in terms of mass fraction: 14% feldspar, 24% purple gold soil, 40% porcelain stone, 18% quartz, high Iron ore soil 4%.

[0021] Processing of Jinban Tianmu glaze enamel and body raw materials, raw material processing includes grinding and screening, proportioning, dehydration, stale, manual molding, trimming and drying processes. In the grinding and screening process, the grinding time for the Jinban Tianmu glaze enamel glaze water is 25% longer than the grinding time for the Jinban Tianmu glaze base body mud; the dehydration process uses a filter press for dehydration, and the moisture content of the raw material afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com