A polycrystalline flexible tile adhesive

A tile adhesive and polycrystalline technology, which is applied in the field of building materials, can solve the problems of flexible tile adhesives such as large plasticity, easy flow and damage to the flatness of the finish, and difficulty in controlling the flatness, so as to improve the penetration and grip force Insufficient, improved waterproof function, improved compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0016] A polycrystalline flexible ceramic tile adhesive, wherein the components and the proportion of parts by mass are as follows: 50 parts of cement, 52 parts of quartz sand, 1 part of redispersible latex powder, 0.4 parts of silicone water repellent, hydroxypropyl 0.6 parts of methyl cellulose ether, 5 parts of water glass, 8 parts of slag powder, and 5 parts of heavy calcium.

Embodiment 3

[0018] A polycrystalline flexible tile adhesive, wherein the components and the proportion of parts by mass are as follows: 45 parts of cement, 48 parts of quartz sand, 0.8 parts of redispersible latex powder, 0.3 parts of silicone water repellent, hydroxypropyl 0.5 parts of methyl cellulose ether, 4.5 parts of water glass, 7 parts of slag powder, and 4 parts of heavy calcium.

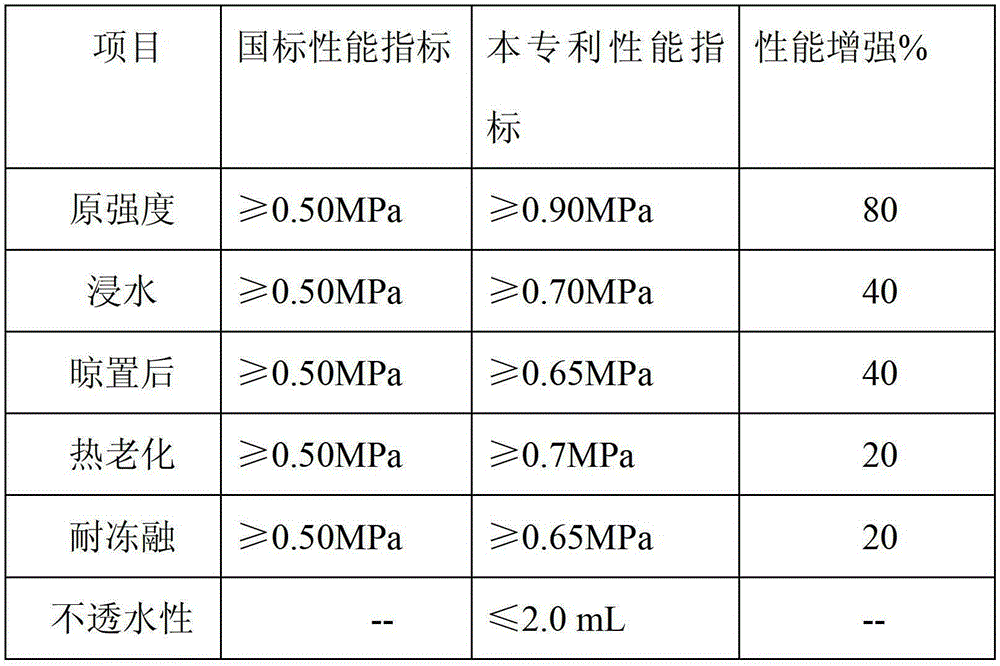

[0019] Based on the above-mentioned embodiments, the technical index comparison between the present invention and the existing ceramic tile adhesive is as follows: 1. Comparison of tensile adhesive strength technical index in different time periods without adding cellulose ether.

[0020] project

7d

28d

48d

original strength

≥0.50MPa

≥0.70MPa

≥0.70MPa

After airing

≥0.45MPa

≥0.60MPa

≥0.60MPa

flooded

≥0.45MPa

≥0.55MPa

≥0.60MPa

[0021] heat aging

≥0.40MPa

≥0.50MPa

≥0.50MPa

Freeze-thaw resista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com