Horizontal guide device of polar crane

A technology of guiding devices and cranes, which is applied in the direction of traveling mechanism, safety device, transportation and packaging, etc., to achieve the effect of improving bearing capacity, improving rigidity and not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

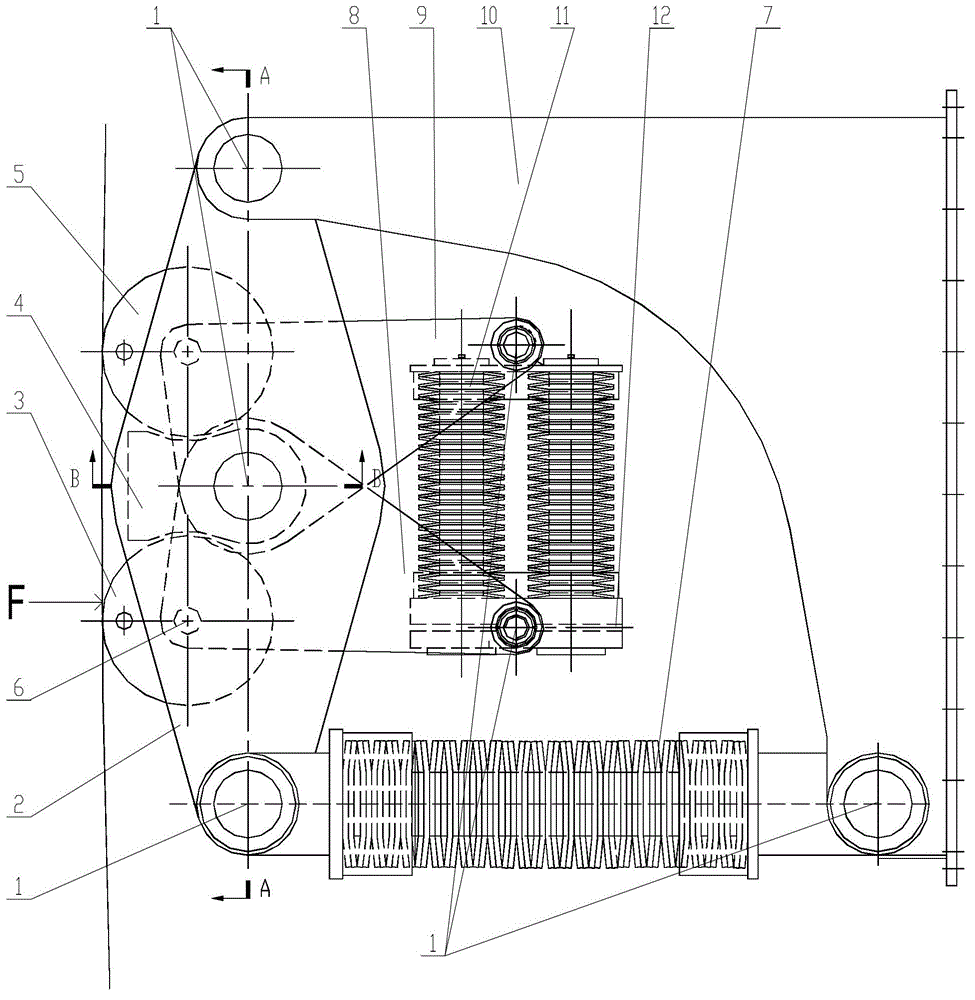

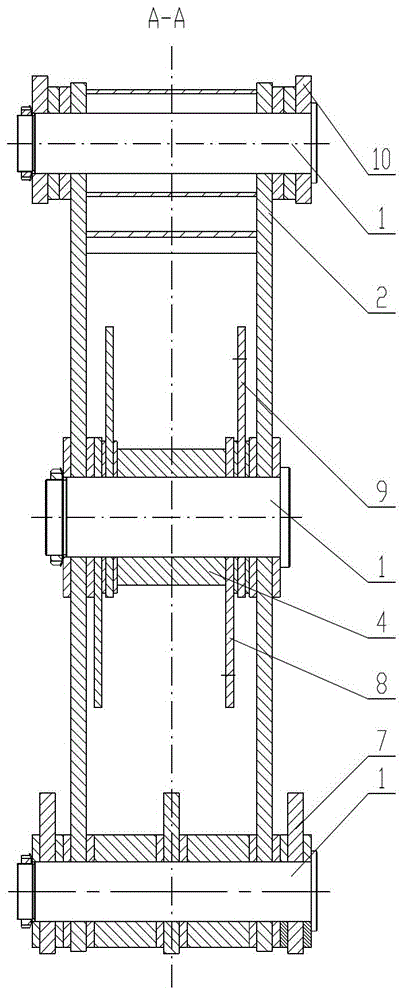

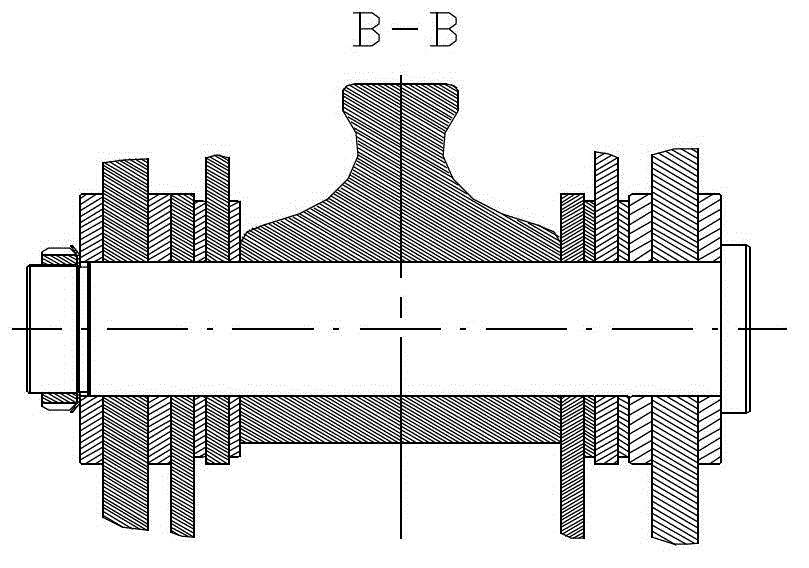

[0018] Such as figure 1 , figure 2 and image 3 As shown, a horizontal guiding device for a ring crane includes: pin shaft 1, wheel shaft 6, base 10, outer splint 2, horizontal wheel I3, travel guide block 4, horizontal wheel II5, inner splint I8, inner splint II9, small plate Spring group 11, shear pin 12 and large disc spring group 7; the base 10 is a right-angled triangle structure in which the hypotenuse is curved toward the right-angled side; an acute-angled end of the base 10 is hinged with an outer splint 2 through a pin shaft 1, The outer splint 2 can rotate around an acute angle end of the base 10 with the pin shaft 1 as the center; the inner splint I8, the inner splint II9 and the travel guide block 4 are hinged in the middle of the outer splint 2 through the pin shaft 1, so that the inner splint I8 and the inner splint The splint II9 can rotate around the outer splint 2 with the pin shaft 1 as the center, so that the stroke guide block 4 is fixed with the outer s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com