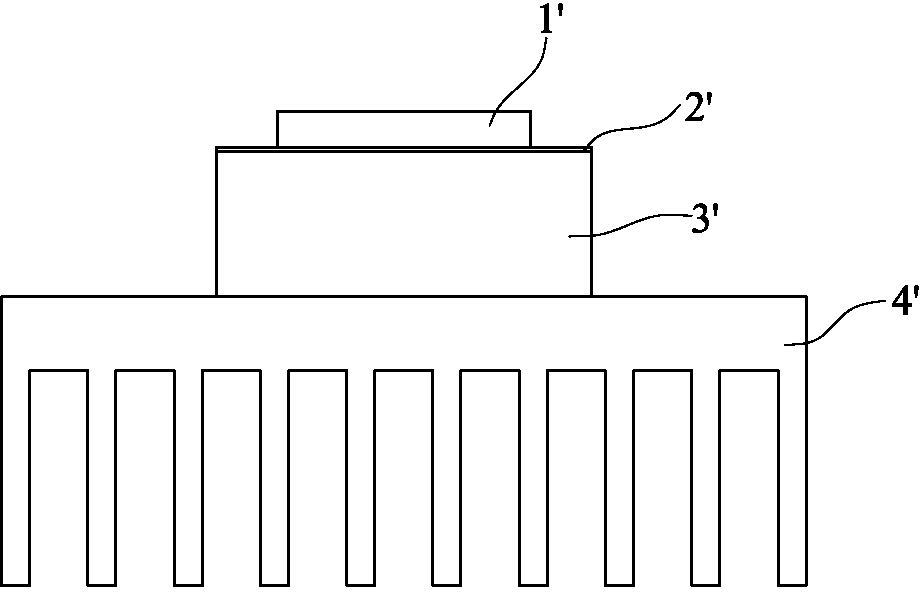

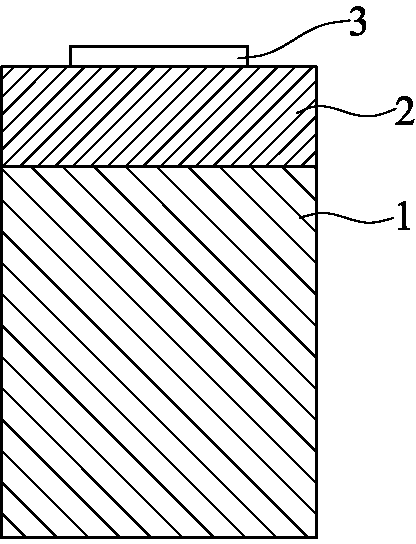

Heat sink material and preparation method thereof

A heat sink material and a part of the technology, applied in the field of heat sink materials and their preparation, can solve the problems of difficult to achieve strength requirements and insufficient mechanical strength, and achieve the effects of low density, high insulation and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1. Batching and pulping: SiC powder, silicon powder, graphite powder and methyl cellulose are powdered according to the mass ratio of 37:44:14:5, wherein the particle size is 3 μm silicon carbide powder and 10 μm silicon carbide powder mass The ratio is 2:1. Take out the methyl cellulose and add a certain amount of water to saturation, heat in a water bath at 60°C, and stir evenly to obtain a transparent solution. Then, silicon carbide powder, silicon powder and graphite powder were mixed and added into the solution, put into a stirrer and stirred for 1 hour, and then the slurry was taken out.

[0032] 2. Graphite substrate decontamination and activation treatment: Use acetone to degrease the graphite substrate at room temperature and wash it with water. Then use HNO 3 (20%) Activate the degreased graphite substrate for 10 minutes, and then wash it with water to increase the contact area between the coating and the substrate material. Finally, the graphite substrate ...

Embodiment 2

[0039] 1. Batching and pulping: SiC powder, silicon powder, carbon black and polyvinyl alcohol are powdered according to the mass ratio of 50:33:13:4, and the particle size of the SiC powder is 0.5 μm. Take out the polyvinyl alcohol and add a certain amount of water to saturation, heat in a water bath at 80°C, and stir evenly to obtain a transparent solution. Then, silicon carbide powder, silicon powder, and carbon black were mixed and added into the solution, put into a stirrer and stirred for 0.5 hours, and then the slurry was taken out.

[0040]2. Graphite substrate decontamination and activation treatment: Use alcohol to degrease the graphite substrate at room temperature and wash it with water. Then use sulfuric acid (30%) to activate the degreased graphite substrate for 10 minutes, and wash it with water to increase the contact area between the coating and the substrate material. Finally, the graphite substrate was ultrasonically cleaned for 10 min.

[0041] 3. Coating...

Embodiment 3

[0047] 1. Batching and pulping: SiC powder, Si powder, carbon black, methyl cellulose and polyvinyl alcohol are powdered according to the mass ratio of 60:24:12:2:2, and the particle size of SiC powder is 5 μm . Take out the methyl cellulose and polyvinyl alcohol, add a certain amount of water to saturation, heat in a water bath at 80°C, and stir evenly to obtain a transparent solution. Then, silicon carbide powder, silicon powder, and carbon black were mixed and added into the solution, put into a stirrer and stirred for 0.5 hours, and then the slurry was taken out.

[0048] 2. Graphite substrate decontamination and activation treatment: Use alcohol to degrease the graphite substrate at room temperature and wash it with water. Then use nitric acid (30%) to activate the degreased graphite substrate for 10 minutes, and wash it with water to increase the contact area between the coating and the substrate material. Finally, the graphite substrate was ultrasonically cleaned for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com