Double-column wave-dissipating body one-time prefabricating construction method

A one-time, wave-dissipating technology, applied in the fields of manufacturing tools, climate change adaptation, coastline protection, etc., can solve the problems of insurmountable quality problems, apparent defects of wave-dissipating bodies, affecting construction efficiency, etc., and achieve good pulp-stopping effect, The effect of reducing apparent quality defects and eliminating repair links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

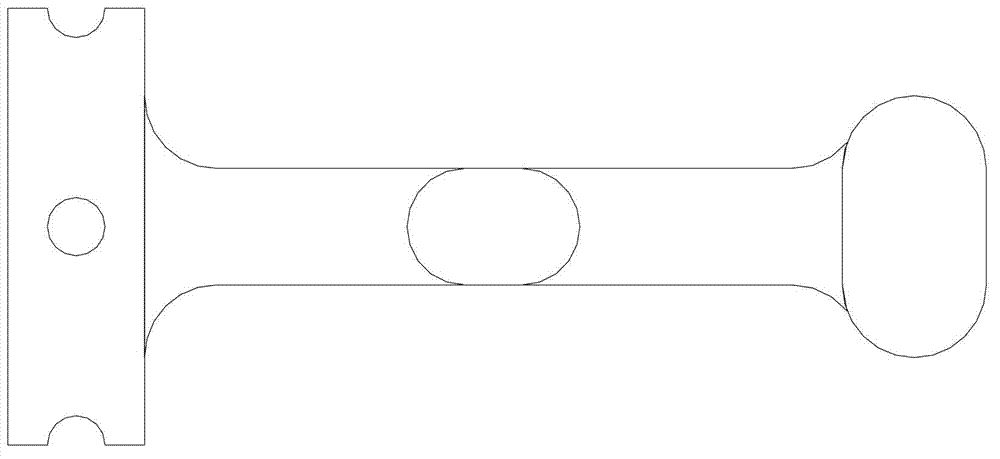

[0052] Example 1, such as Figure 1-3 It is a schematic diagram of the structure of the double-column wave-dissipating body disclosed in this embodiment, Figure 4-6 A schematic diagram of the formwork for prefabricating the double-column wave-dissipating body is disclosed. The one-time prefabricated construction method of the above-mentioned double-column wave-dissipating body includes the following steps:

[0053] (1) Concrete bottom tire prefabrication

[0054] Set out the bottom tire on the concrete floor that has been poured to ensure the accuracy of the position of the concrete bottom tire;

[0055] Support the concrete bottom tire formwork along the laid line, and use a level to measure the elevation of the formwork top to ensure the level;

[0056] After passing the acceptance check, concrete pouring is carried out, artificial ash is placed, and a flat vibrator is used to vibrate to ensure that the concrete is dense and smooth;

[0057] (2) laying out the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com