Method for preparing perfluorinated silane modified magnetic extraction stirring stick

A technology of perfluorosilane and magnetic stirring, which is applied in the field of trace analysis of organic pollutants, can solve problems such as temperature limitation and coating fracture, and achieve the effect of simple operation, low cost and strong adsorption force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

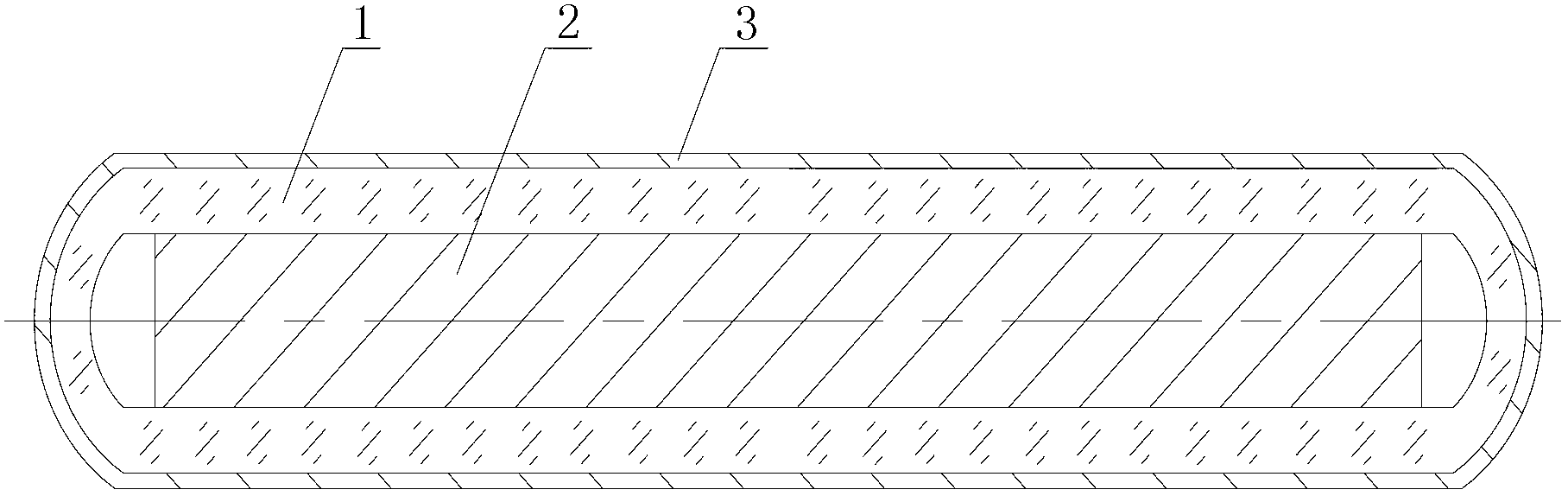

[0022] The steps of the preparation method of the perfluorosilane-modified magnetic extraction stirring bar of this embodiment are as follows:

[0023] 1. Prepare a magnetic stirring bar

[0024] Select a glass tube 1 with a length of 2 cm and an inner diameter of 2 mm, seal and package an iron core 2 with an outer diameter of 2 mm in the glass tube 1 and seal both ends of the glass tube 1 with an alcohol blowtorch to prepare a magnetic stirring bar. The specific length of the glass tube 1 can be arbitrarily selected in the range of 2 to 3 cm, and the inner diameter can be in the range of 2 to 4 mm. The outer diameter of the iron core 2 can also be slightly smaller than the inner diameter of the glass tube 1. When the glass tube 1 cannot move, the iron core 2 The length is less than the length of the glass tube 1.

[0025] 2. Surface pretreatment of magnetic stirring bar

[0026] The outer surface of the magnetic stirring rod is treated with dichloromethane for 20-30 minutes...

Embodiment 2

[0030] The steps of the preparation method of the perfluorosilane-modified magnetic extraction stirring bar of this embodiment are as follows:

[0031] In the surface pretreatment step 2 of the magnetic stirring bar, the outer surface of the magnetic stirring bar is treated with dichloromethane for 20-30 minutes, soaked in 1mol / L NaOH aqueous solution for 6-12 hours, and soaked in 0.1mol / L HCl aqueous solution for 1-2 hours. After 3 hours, wash with deionized water until neutral, place in a vacuum drying oven at 80°C, and dry at a vacuum of 0.06MPa for 3 hours.

[0032] In step 3 of preparing a perfluorosilane-modified magnetic extraction stir bar, place the pretreated magnetic stir bar in 5 mL of 1.71 mg / mL 1H,1H,2H,2H-perfluorodecyltrichlorosilane toluene solution , react for 5 hours at 50°C and a vacuum of 0.05MPa, a perfluorosilane layer 3 is formed on the surface of the glass tube 1, take out the magnetic stirring bar, place it in a vacuum drying oven, and dry at 50°C and...

Embodiment 3

[0035] The steps of the preparation method of the perfluorosilane-modified magnetic extraction stirring bar of this embodiment are as follows:

[0036]In the surface pretreatment step 2 of the magnetic stirring bar, the outer surface of the magnetic stirring bar is treated with dichloromethane for 20-30 minutes, soaked in 1mol / L NaOH aqueous solution for 6-12 hours, and soaked in 0.1mol / L HCl aqueous solution for 1-2 hours. After 3 hours, wash with deionized water until neutral, place in a vacuum drying oven at 100°C, and dry at a vacuum of 0.05MPa for 1 hour.

[0037] In step 3 of preparing a perfluorosilane-modified magnetic extraction stir bar, place the pretreated magnetic stir bar in 5 mL of 1.71 mg / mL 1H,1H,2H,2H-perfluorodecyltrichlorosilane toluene solution , react at 90°C and a vacuum of 0.05MPa for 5 hours, a perfluorosilane layer 3 is formed on the surface of the glass tube 1, take out the magnetic stirring bar, place it in a vacuum drying oven, and dry at 50°C and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com