Positive pole piece and preparation method thereof and battery

A positive electrode plate and positive electrode activity technology, applied in the field of positive electrode plate and its preparation, can solve problems such as cracks in the positive electrode plate of a battery, and achieve the effects of good electrical conductivity, improved bonding strength, and improved rate performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] At the same time, the present invention also discloses a method for preparing the above-mentioned positive electrode sheet, including:

[0025] S1. Uniformly mix the linear conductive material, polyvinylpyrrolidone, polyvinylidene fluoride, and a solvent to obtain a network conductive layer slurry, wherein the network conductive layer slurry has a viscosity of 200-1000Pa·s;

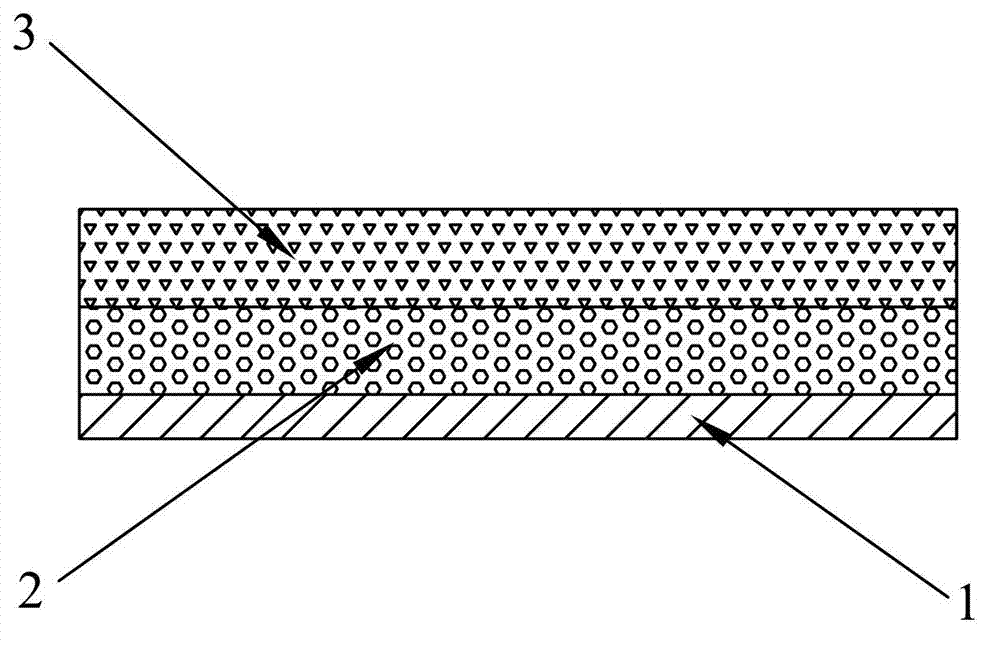

[0026] S2. Coating the network conductive layer slurry on the positive electrode current collector and baking to form a network conductive layer with a thickness of 2-10 μm on the positive electrode current collector;

[0027] S3, forming a positive electrode active layer on the surface of the network conductive layer.

[0028] Wherein, the linear conductive material, polyvinylpyrrolidone, polyvinylidene fluoride and solvent are mixed at a mass ratio of 10-70:5-10:5-20:900-980.

[0029] After forming the above-mentioned conductive network layer slurry, the conductive network layer slurry is coated...

Embodiment 1

[0047] This embodiment is used to illustrate the positive electrode sheet disclosed in the present invention and its preparation method.

[0048] Network conductive layer slurry preparation:

[0049] Mix CNT, PVP, binder PVDF, and solvent NMP uniformly at a mass ratio of 6:1:2:91, with a viscosity of 200-1000Pa·s, and coat the above slurry on the current collector with a coating thickness of 4-5μm , baked to obtain a current collector coated with a network conductive layer.

[0050] Positive pole piece preparation:

[0051] Weigh 97 grams of lithium cobaltate active material, 1 gram of CNT, and 3 grams of binder PVDF, mix them, add 200 grams of NMP and stir to obtain the active material slurry, and coat it on the aluminum current collector treated with the coating slurry , a drying temperature of 95° C., and a coating speed of 6 m / min to obtain a positive electrode sheet.

[0052] Battery production:

[0053] Prepare the negative pole piece according to the following metho...

Embodiment 2

[0055] This embodiment is used to illustrate the positive electrode sheet disclosed in the present invention and its preparation method.

[0056] Network conductive layer slurry preparation:

[0057] Mix metal silver wire (diameter 1.0 μm, length 50 μm), PVP, binder PVDF, and solvent NMP in a mass ratio of 1:1:1:97, with a viscosity of 200-1000 Pa s, and coat the above slurry on the set On the fluid, the coating thickness is 2-10 μm, and baked to obtain a current collector coated with a network conductive layer.

[0058] Positive pole piece preparation:

[0059] Weigh 97 grams of lithium cobaltate active material, 1 gram of carbon fiber VGCF, and 3 grams of binder PVDF to mix, add 200 grams of NMP and stir to obtain active material slurry, which is coated on the aluminum current collector treated with coating slurry above, the drying temperature is 95°C, the coating speed is 6m / min, and the positive electrode sheet is obtained.

[0060] Battery production:

[0061] Prepare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com