Circuit breaker and insulation method thereof

A technology for vacuum circuit breakers and insulating parts, which is applied to high-voltage air circuit breakers, circuits, electrical components, etc., can solve the problems of short circuit of the moving end of the vacuum bubble, the overall size of the circuit breaker, and the air breakdown of the insulating barrel, etc. Compact, reliability-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

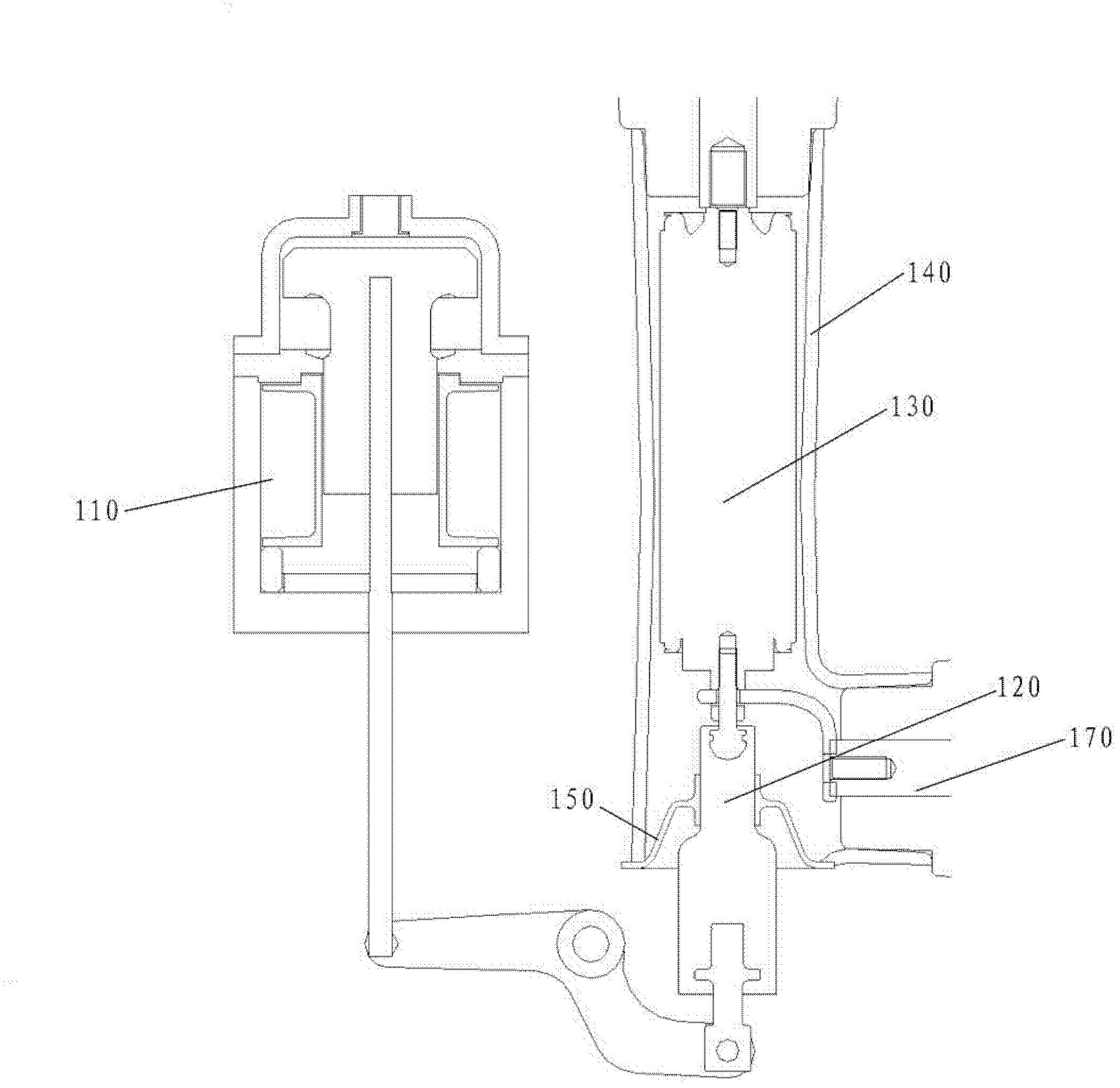

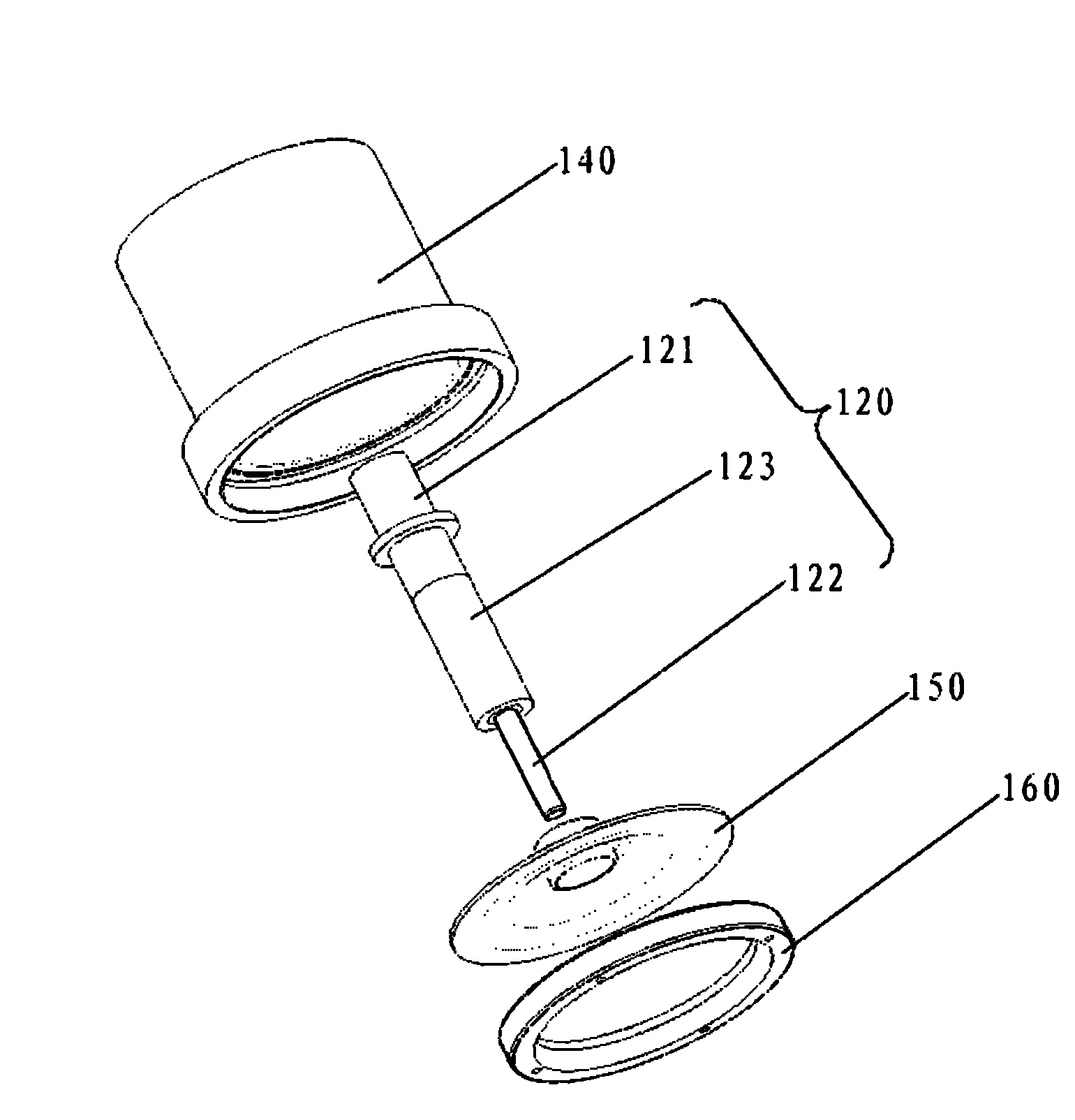

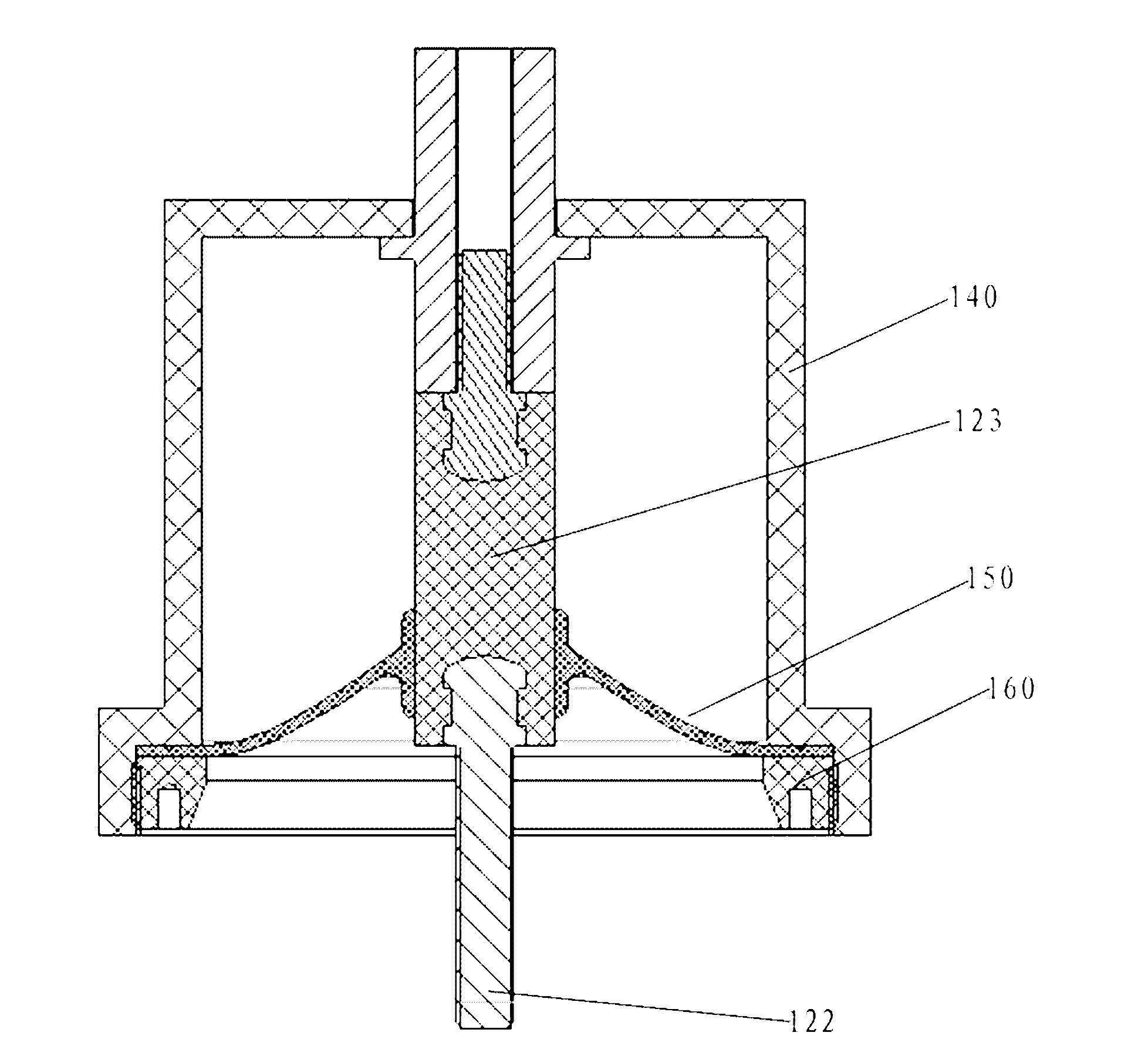

[0031] Hereinafter, preferred embodiments according to the present invention will be described in detail with reference to the accompanying drawings. First of all, it should be pointed out that the present invention only involves the improvement of the electrical insulation of the insulating pull rod, therefore, in the following description, the detailed description of other structures and components of the vacuum circuit breaker will be omitted, and those skilled in the art can The specific structures of these other parts and components are obtained with the knowledge of their own background technology. In addition, in the following description and appended claims, unless otherwise specified, each term should be interpreted in a generally broad sense, for example, "connected" means to include one element directly connected to another element, wherein there are no intervening elements , and also includes that one element is connected to another element through other intermedia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com