Microscope machine platform structure

A technology for microscopes and worktables, which is applied in optics, instruments, projection devices, etc., can solve problems such as wafer collisions, microscope defects, and damaged wafers, and achieve cost savings, simple structure, and avoid potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

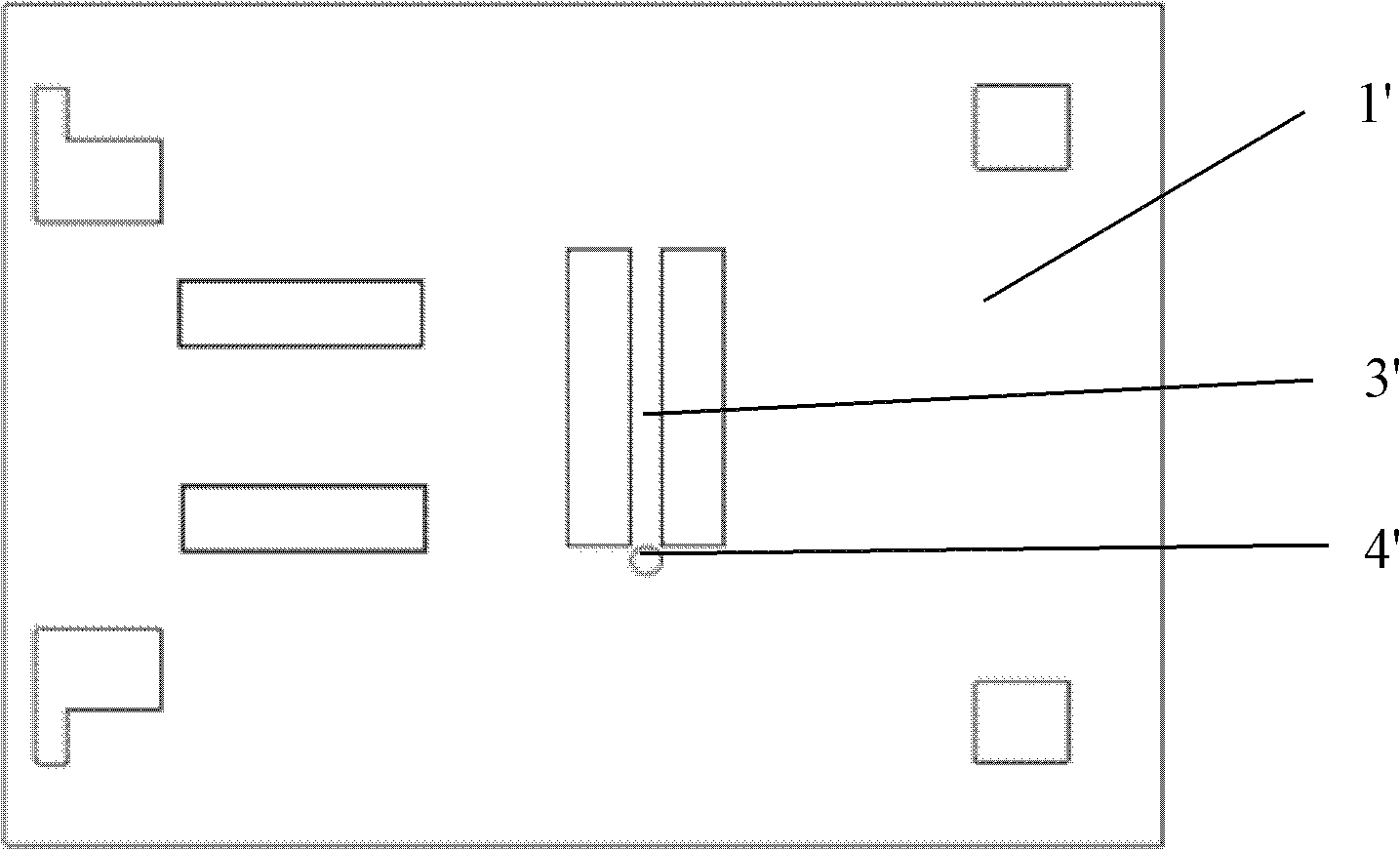

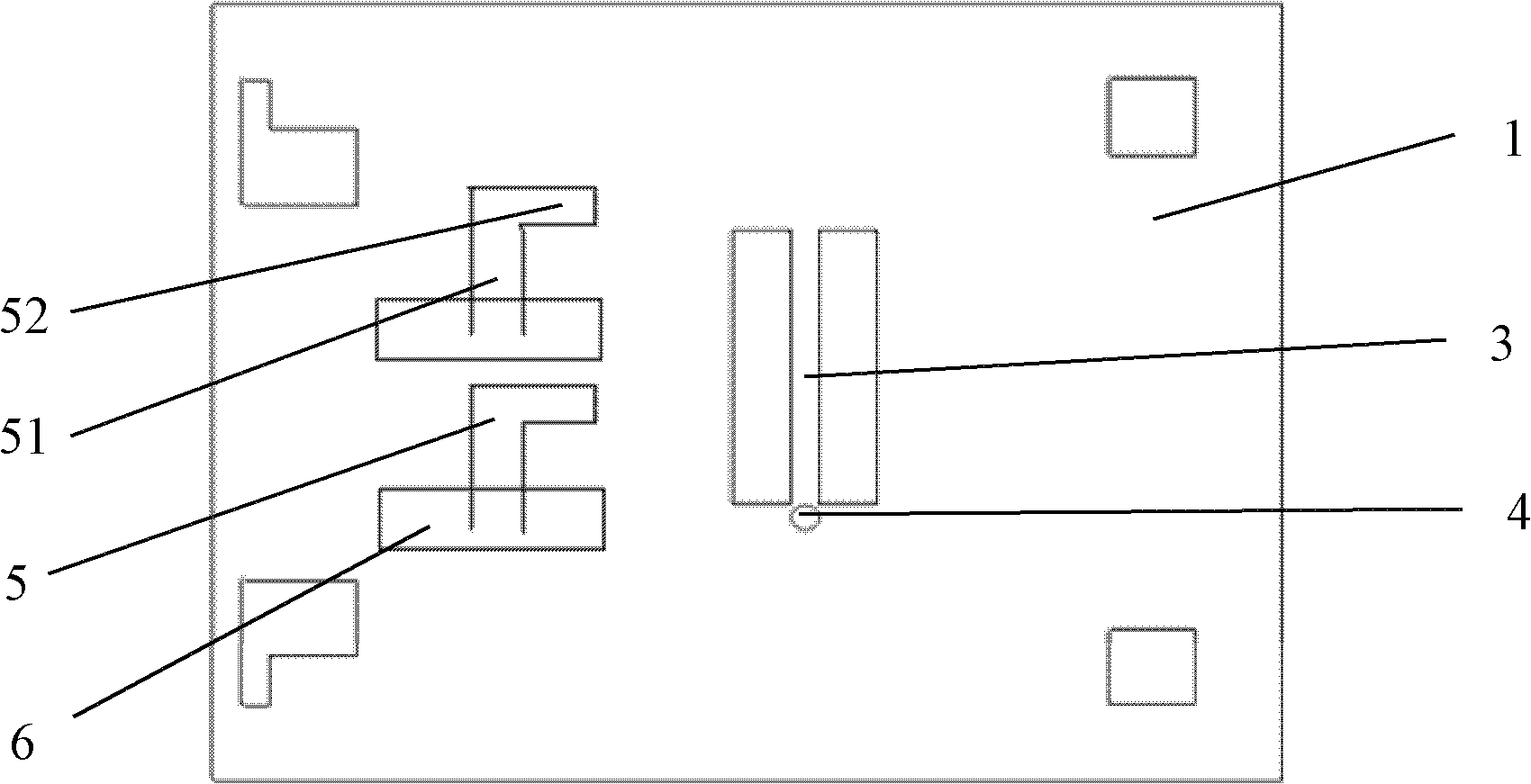

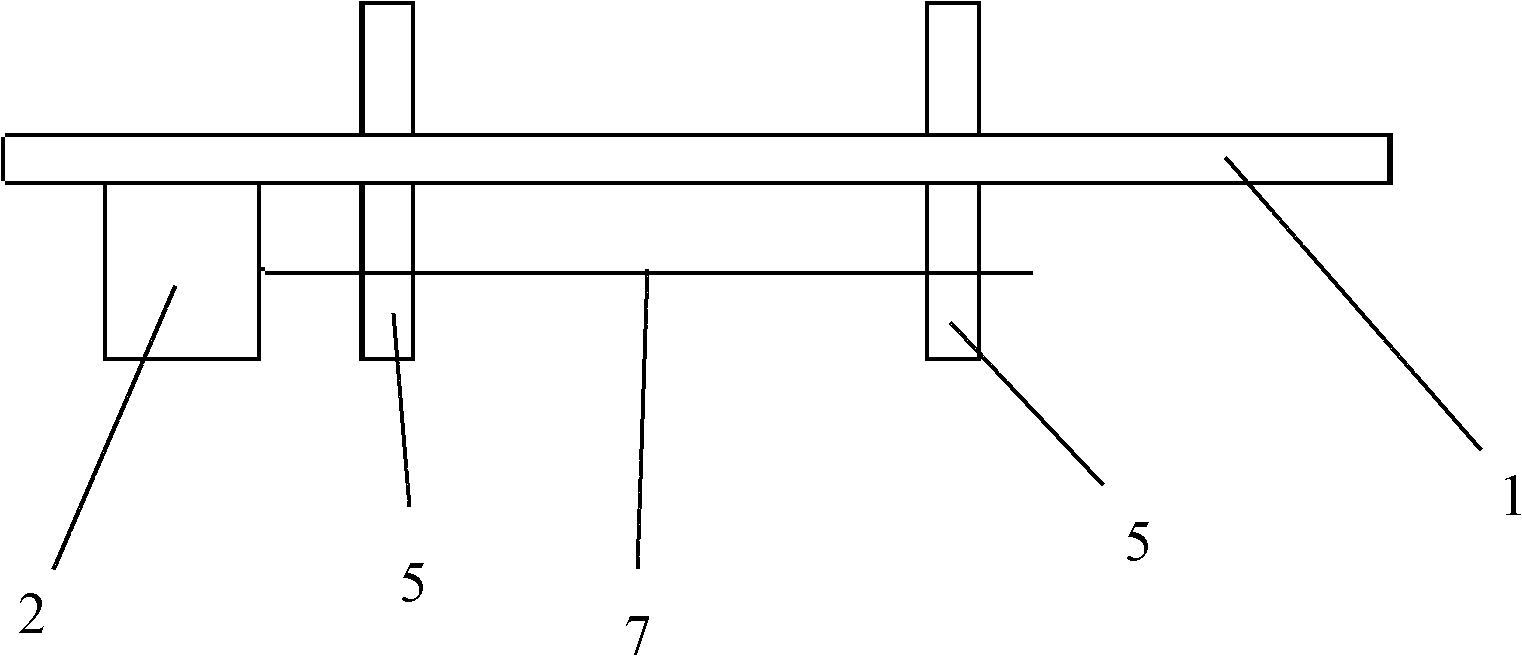

[0027] see figure 1 As shown, a microscope machine structure in the prior art is used to inspect wafers. The microscope is equipped with a robot arm for grabbing the wafer. Several wafers are accommodated in a wafer box. The wafer box is fixed on the microscope machine structure. The structure of the microscope machine includes a worktable 1' that can move up and down and a drive motor that drives the worktable 1' to move up and down. The worktable 1' is provided with a slot 3' for positioning the wafer cassette and a sensor 4' for sensing whether the wafer cassette is installed on the worktable 1'.

[0028] The working principle of the microscope machine structure in the prior art is: during normal testing, when the wafer cassette with the wafer installed is correctly clamped into the slot 3', the sensor 4' senses that the wafer cassette has been correctly installed in the slot 3'. On the working table 1', an induction signal will be sent out to indicate that the equipmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com