Method for testing abrasion resistant performance of mesh spot of light guide plate

A light guide plate network point and testing method technology, applied in the direction of testing wear resistance, etc., can solve the problems of unable to test network point wear resistance, peeling, network point adhesion decline, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

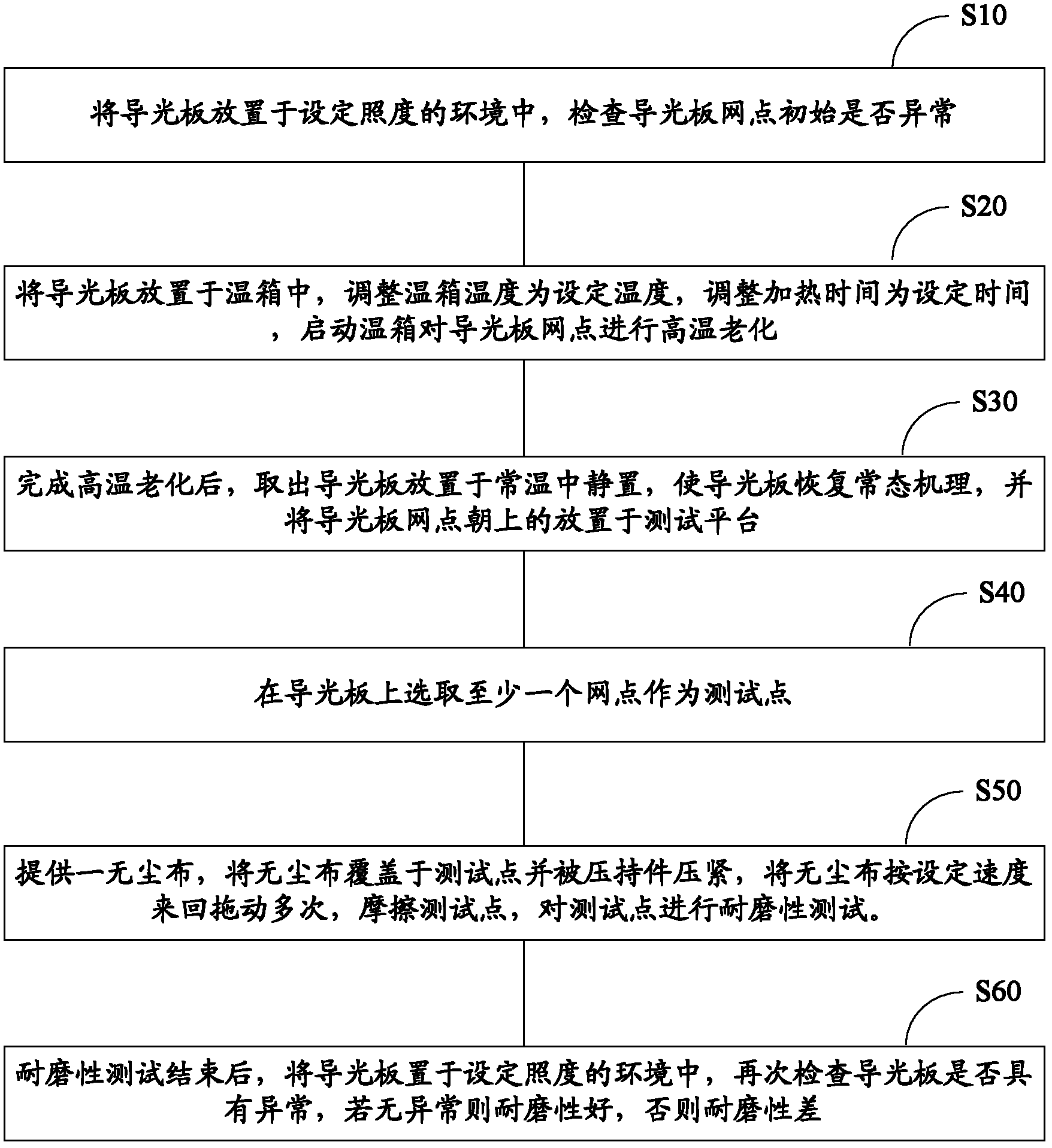

[0024] figure 1 It is a flow chart of a method for testing the abrasion resistance of a light guide plate in an embodiment. The method includes:

[0025] S10: Place the light guide plate in an environment with a set illuminance, and check whether the initial dots of the light guide plate are abnormal.

[0026] Before the light guide plate is tested, the regular quality inspection of the light guide plate is firstly carried out to confirm the condition of the dots of the light guide plate before the test, so as to ensure the validity of the test. Specifically: place the light guide plate in an environment with a set illuminance of 200 lux, and visually check whether there are abnormalities such as black spots, missing spots, and defects in the initial dots of the light guide plate. Further, and record, as the initial record. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com