Double-air-gap superconductive direct-drive wind power generating set

A wind turbine, double air gap technology, applied in wind turbine components, wind turbine combinations, wind turbines, etc., can solve problems such as transportation difficulties and excessive generator volume, and achieve bearing cost savings, weight reduction and Volume, the effect of improving torque density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

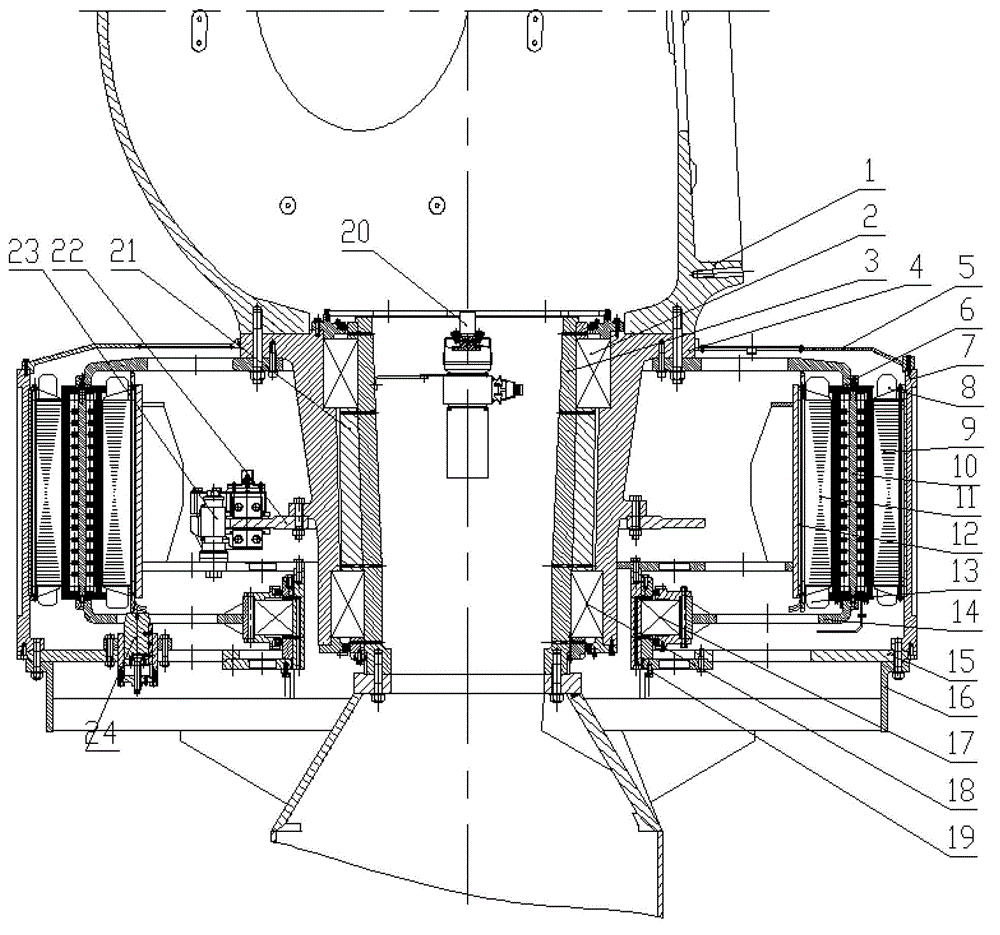

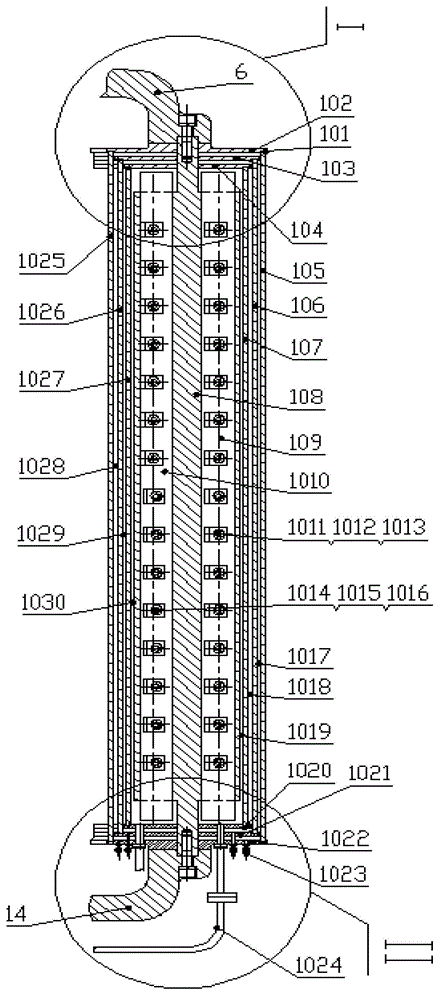

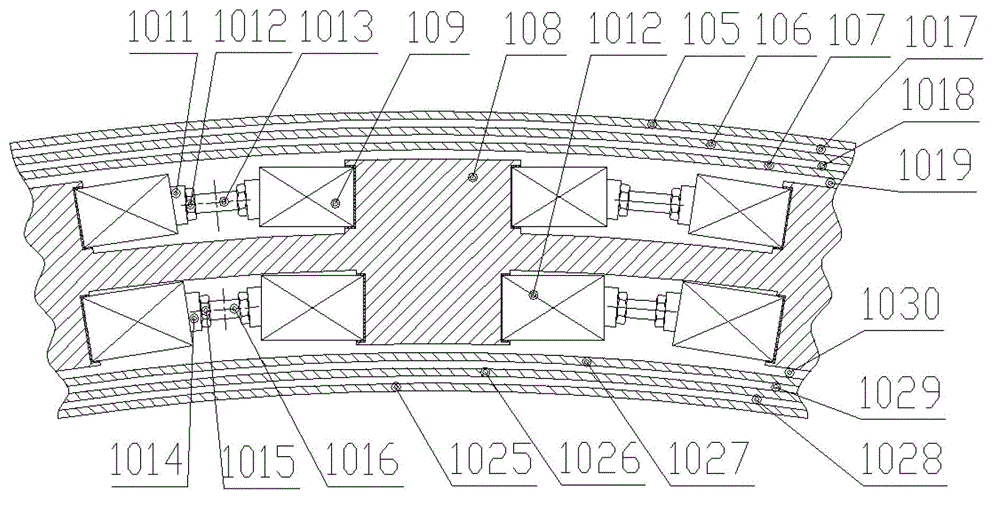

[0033] see figure 1 As shown in the figure, only the main parts and components of the overall structure are marked in the figure, and some fastening bolts and nuts are not marked. The present invention relates to a double-air-gap superconducting direct-drive wind power generator set, which mainly includes: a hub 1, a front bearing sleeve 2, a fixed shaft 3, a hollow rotating shaft 4, a front flange 5, a rotor turntable 6, and a generator casing 7. Outer stator winding 8, outer stator core 9, rotor 10, inner stator core 11, inner stator bracket 12, inner stator winding 13, rotor rear support 14, rear flange 15, frame 16, rotor centering bearing Part cover 17, rear bearing part cover 18, rotor centering bearing bracket 19, slip ring system 20, bushing 21, rotor brake disc 22, rotor brake mechanism 23 and rotor locking device 24.

[0034] The fixed shaft 3 and the frame 16 are fastened and connected by fastening bolts, the front bearing part sleeve 2 and the rear bearing part sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com