Air flue well used for wind tower power generation station

A technology for wind tower power stations and air ducts, applied in wind power generation, wind power generator components, wind power engines, etc., can solve problems such as single structure of hot air flow channels, difficulty in forming sufficient upward thrust, and difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

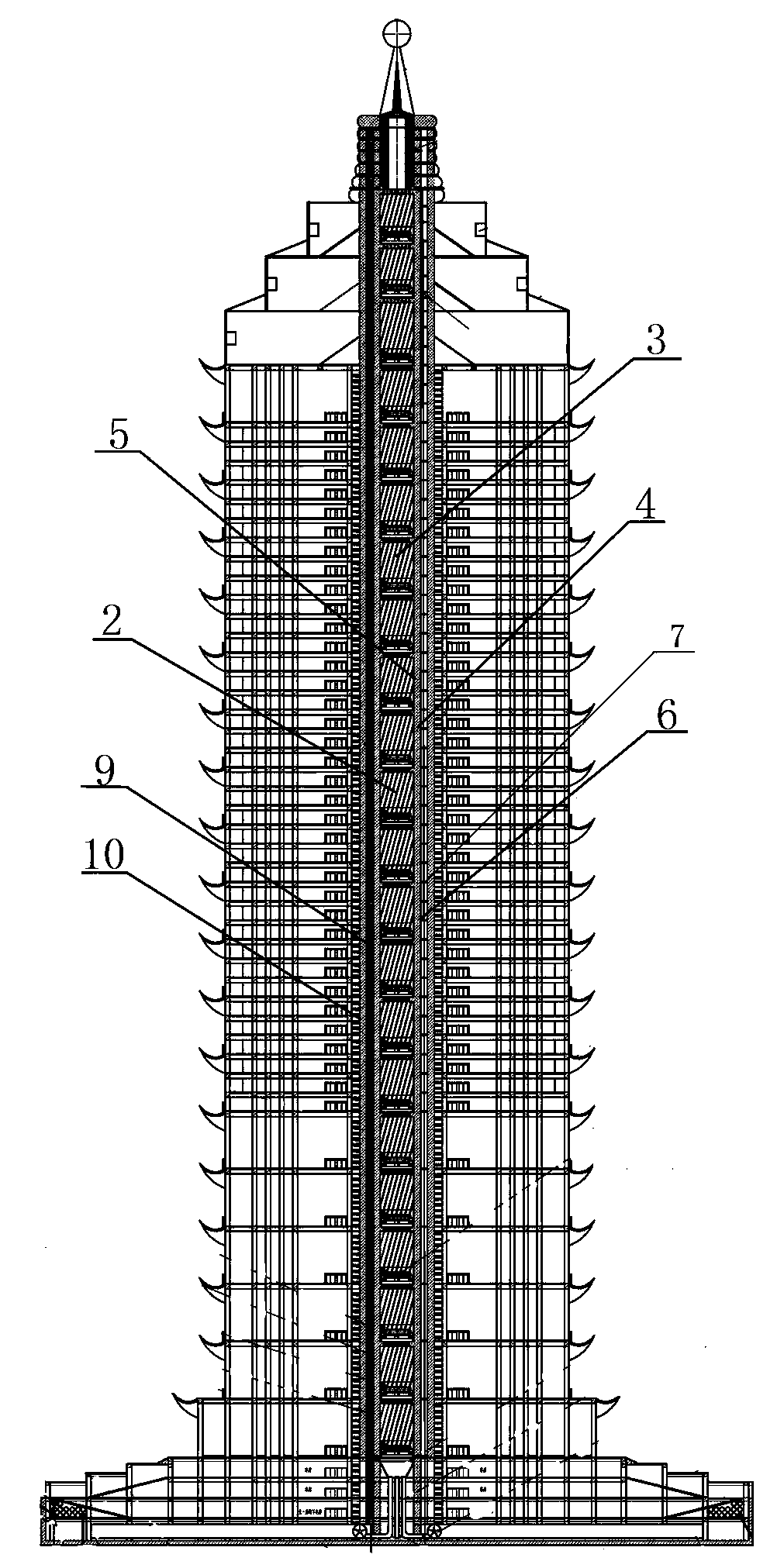

[0033] The best preferred embodiment 1: an air duct shaft for a wind tower power station

[0034] figure 1 It is a schematic architectural diagram of the blade cylinder wall installed with the wind duct well structure of the wind tower power station of the present invention. It includes stationary blades 2, running rails 3, blade cylinder walls 4, duct well outer wall pipes 7, air duct well inner walls 9, air duct well outer walls 10, cylinder wall outer walls 6, and cylinder wall inner walls 5. The running track 3 is formed between the stationary blades 2 , the inner wall 9 of the air duct well is fixedly connected with the outer wall 6 of the tube wall 6 through the outer wall pipe 7 of the air duct well, and the outer wall pipe 7 of the air duct well is arranged around the inner wall 10 of the air duct well.

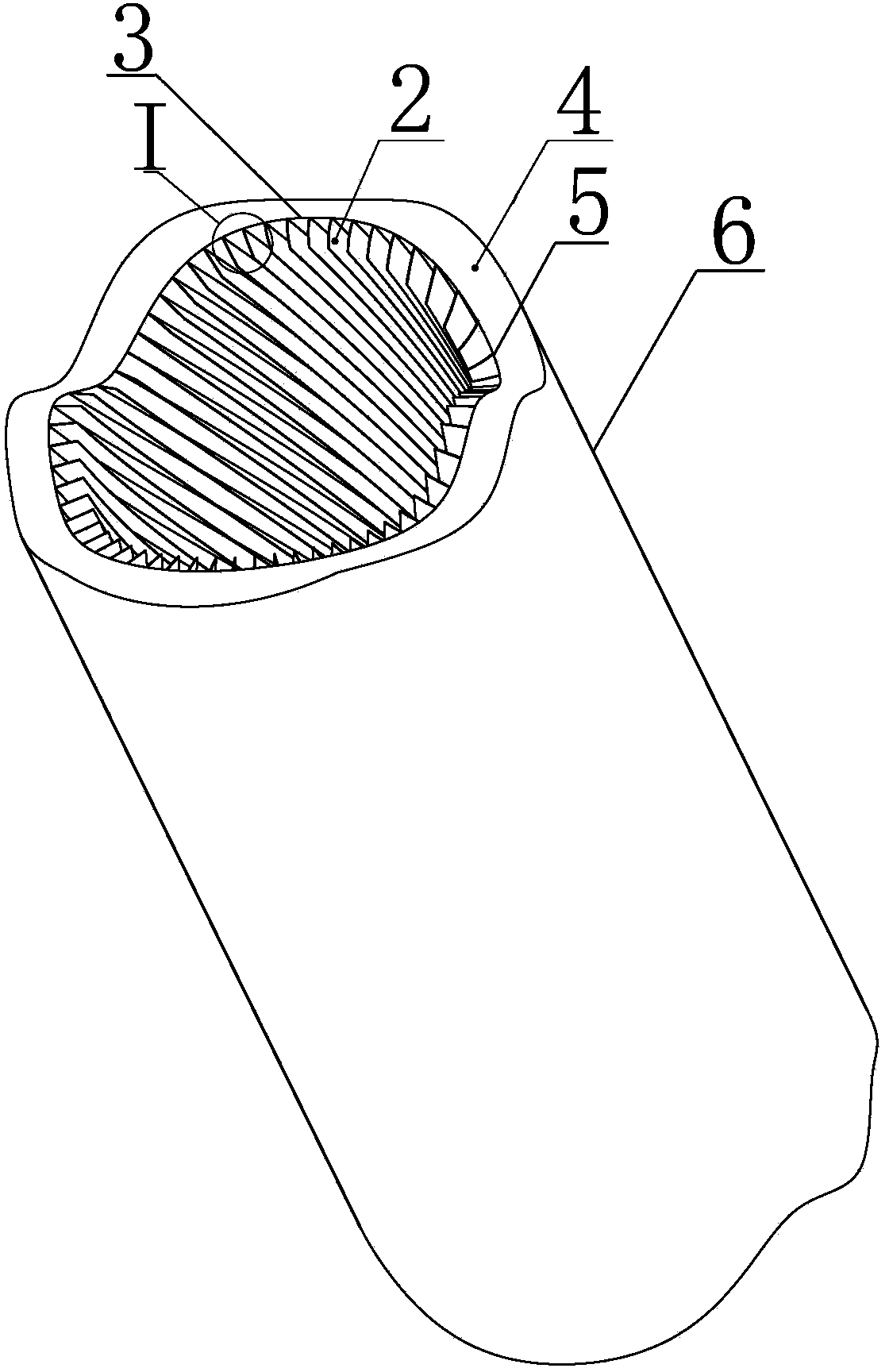

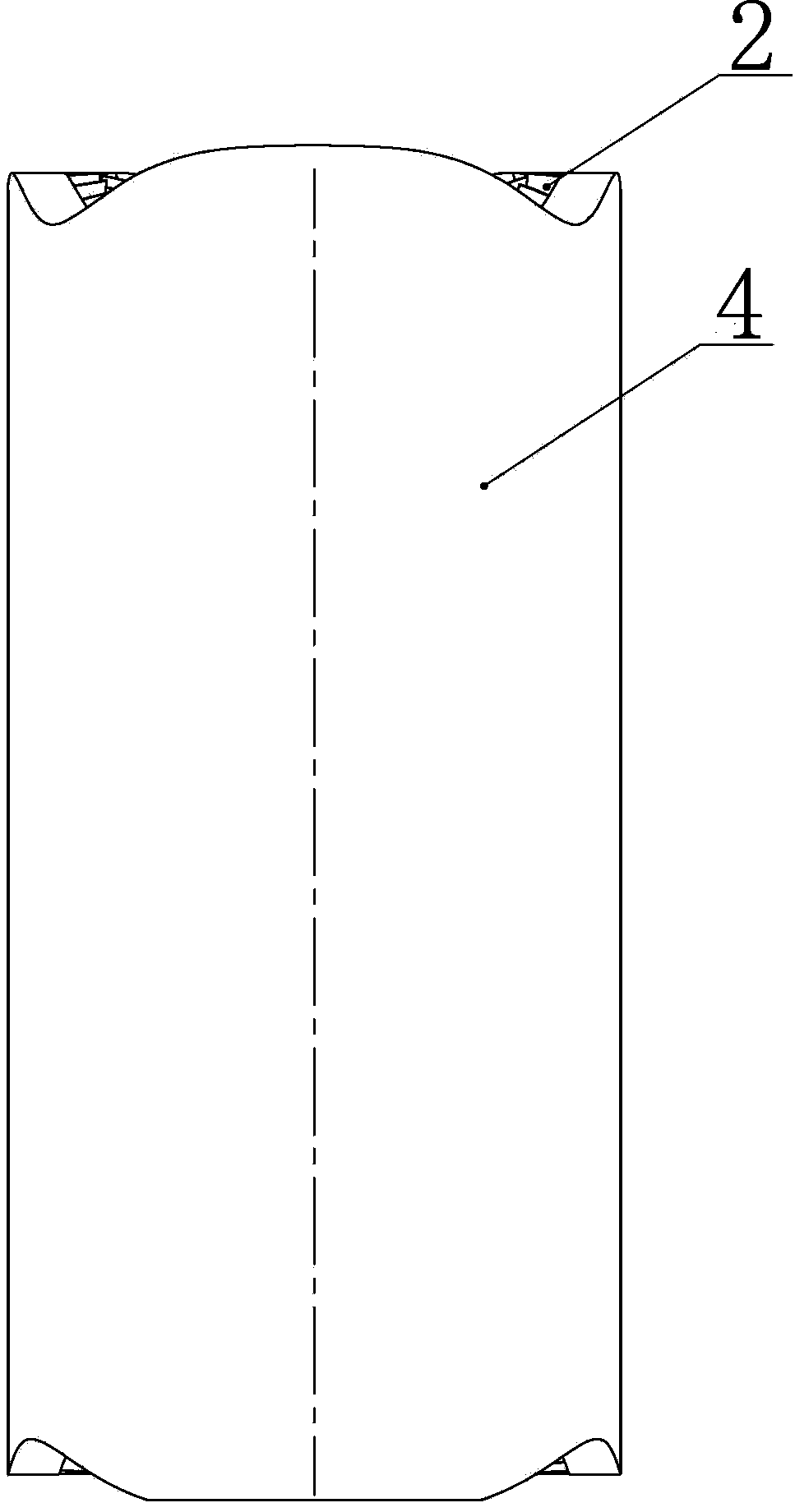

[0035] figure 2 A three-dimensional structure diagram of an air duct shaft for a wind tower power station according to the present invention is shown, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com