Low-cost variable pitch system

A pitch system, low-cost technology, applied in the control of wind turbines, wind power generation, wind turbines and other directions, can solve the problems of increasing hardware and labor costs, increasing system complexity, and high PLC modules, saving modules, reducing The effect of generating heat and reducing the number of wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

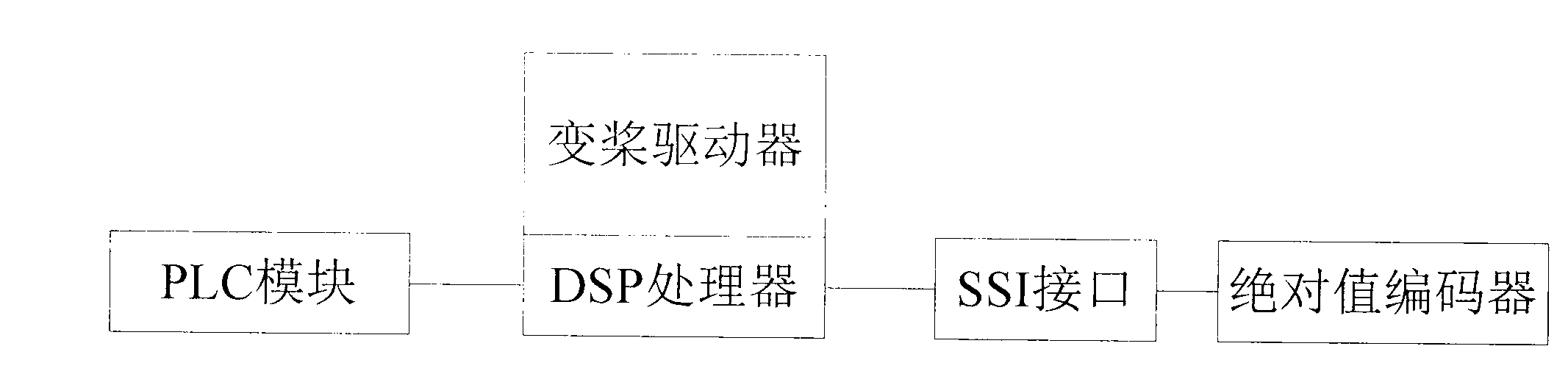

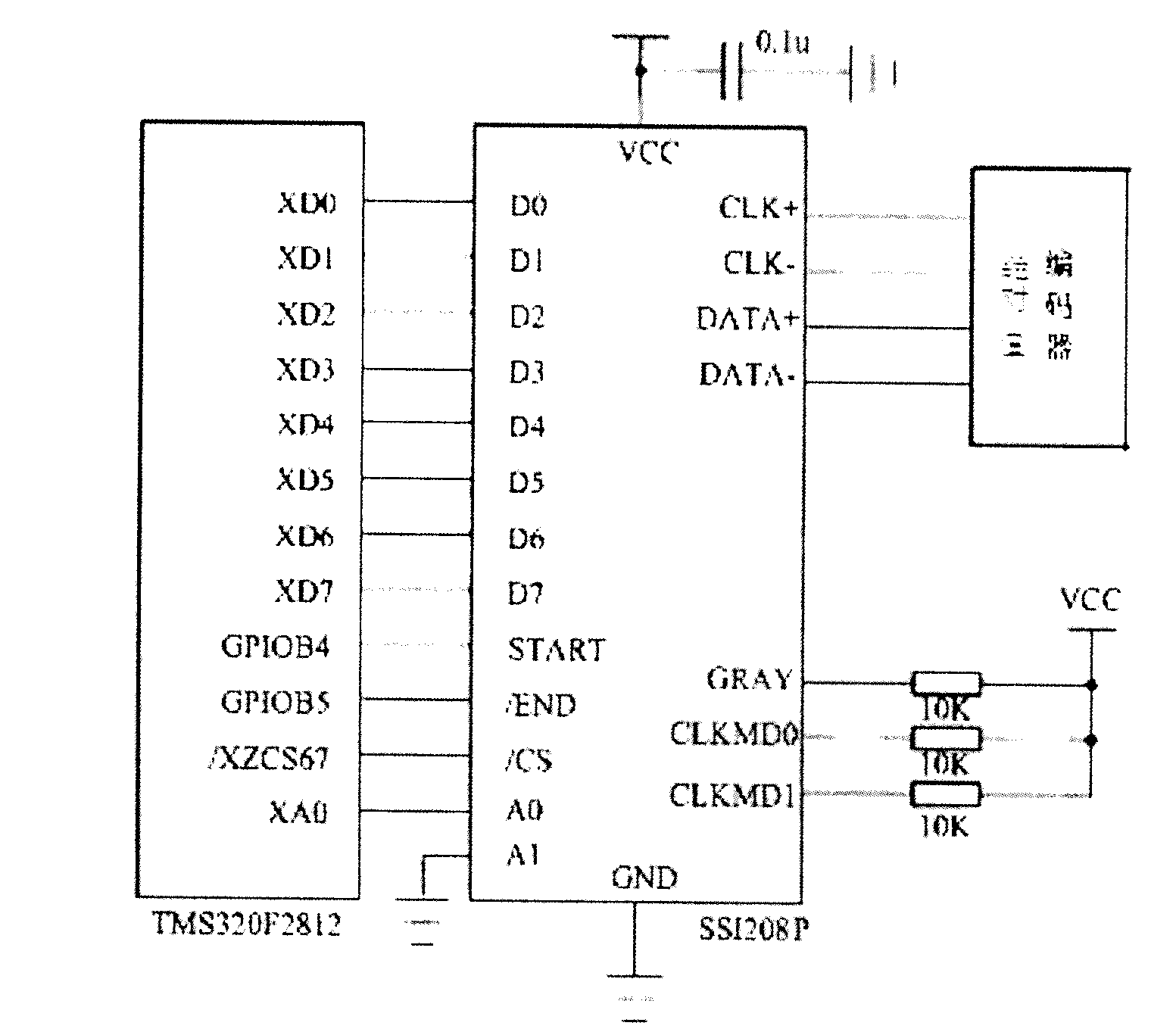

[0015] A low-cost pitch system of this embodiment, such as Figure 1 ~ Figure 2 As shown, it includes a PLC module, an absolute encoder and a pitch driver. The pitch driver is equipped with a DSP processor. The output of the absolute encoder is connected to the input of the DSP processor through the SSI interface, and the output of the DSP processor is The terminal communicates with the input terminal of the PLC module. Among them: the absolute value encoder is a single-turn 16-bit absolute angle encoder, and the output data form of the absolute value encoder is gray code; the DSP processor is TMS320F2812; the SSI interface is a SSI208P interface to parallel port module; the output of the absolute value encoder connected to the input port of the SSI208P interface-to-parallel port module; the eight-bit data bus D0~D7 of the SSI208P interface-to-parallel port module is connected to the lower eight-bit data bus XD0~XD7 of TMS320F2812; because the absolute value encoder used is 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com