Composite solvent and extraction method for extracting and separating aromatic hydrocarbons

A composite solvent and aromatics separation technology, applied in extraction and purification/separation, refined hydrocarbon oil, organic chemistry, etc., can solve problems such as heat increase, achieve the effects of avoiding increased energy consumption, reducing solvent consumption, and improving the recovery rate of aromatics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

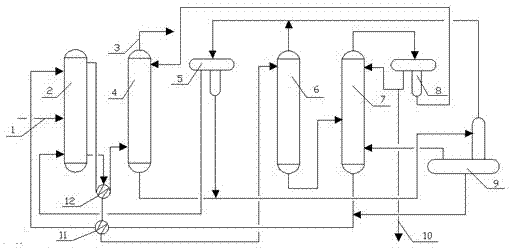

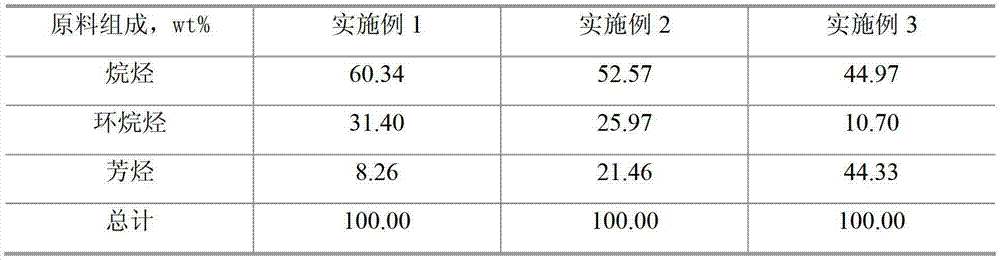

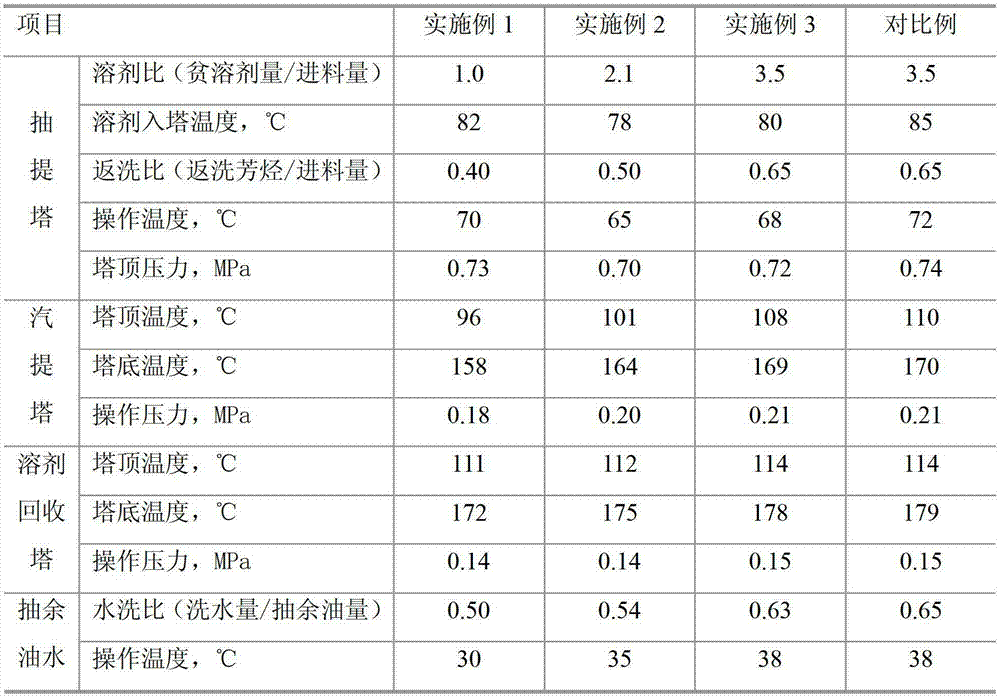

[0017] Using straight-run naphtha as raw material, its composition is listed in Table 1. Carry out liquid-liquid extraction to recover benzene and toluene according to the process shown in the accompanying drawing, the composite solvent used is composed of: 60g sulfolane, 32g N-methylpyrrolidone and 8.0g polyethylene glycol 400. The main operating conditions of each tower are shown in Table 2, and the separation results of aromatics are shown in Table 3.

Embodiment 2

[0019] Condensate oil is used as raw material, and its composition is listed in Table 1. Carry out liquid-liquid extraction to recover benzene and toluene according to the process shown in the accompanying drawing, the composite solvent used is composed of: 60g N-formylmorpholine, 32g N-methylpyrrolidone and 8.0g ethylene glycol. The main operating conditions of each tower are shown in Table 2, and the separation results of aromatics are shown in Table 3.

Embodiment 3

[0021] Using reformed gasoline as raw material, its composition is listed in Table 1. Carry out liquid-liquid extraction recovery benzene and toluene according to the process shown in the accompanying drawing, the composite solvent adopted is composed of: 60g sulfolane, 32g N-methylpyrrolidone and 8.0g ethylene glycol. The main operating conditions of each tower are shown in Table 2, and the separation results of aromatics are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com