Method and system for obtaining coke weight based on dry quenching lifting device

A technology of dry quenching and weight, applied in the cooling of coke, coke oven, transportation and packaging, etc., can solve the problems of large overall investment, unsuitability, complicated structure of rail weighing method, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

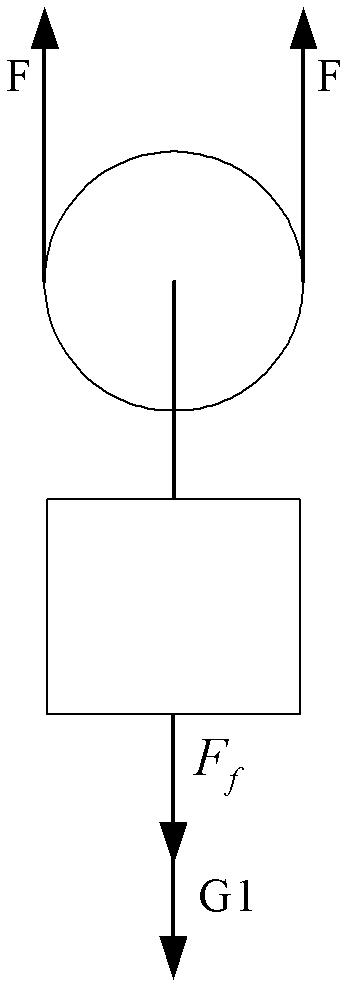

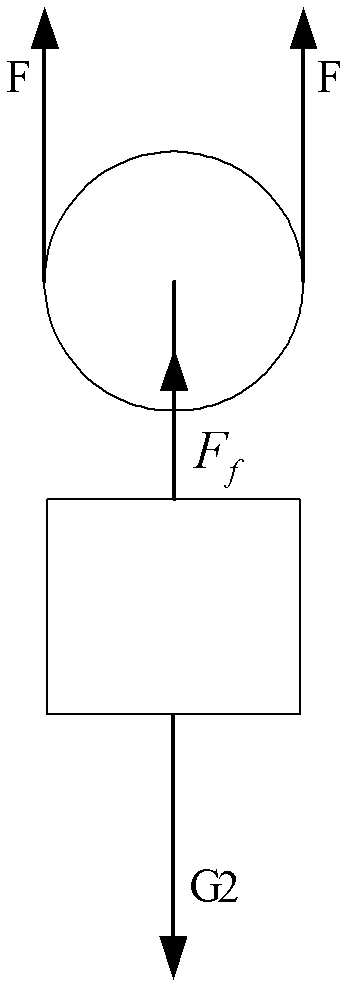

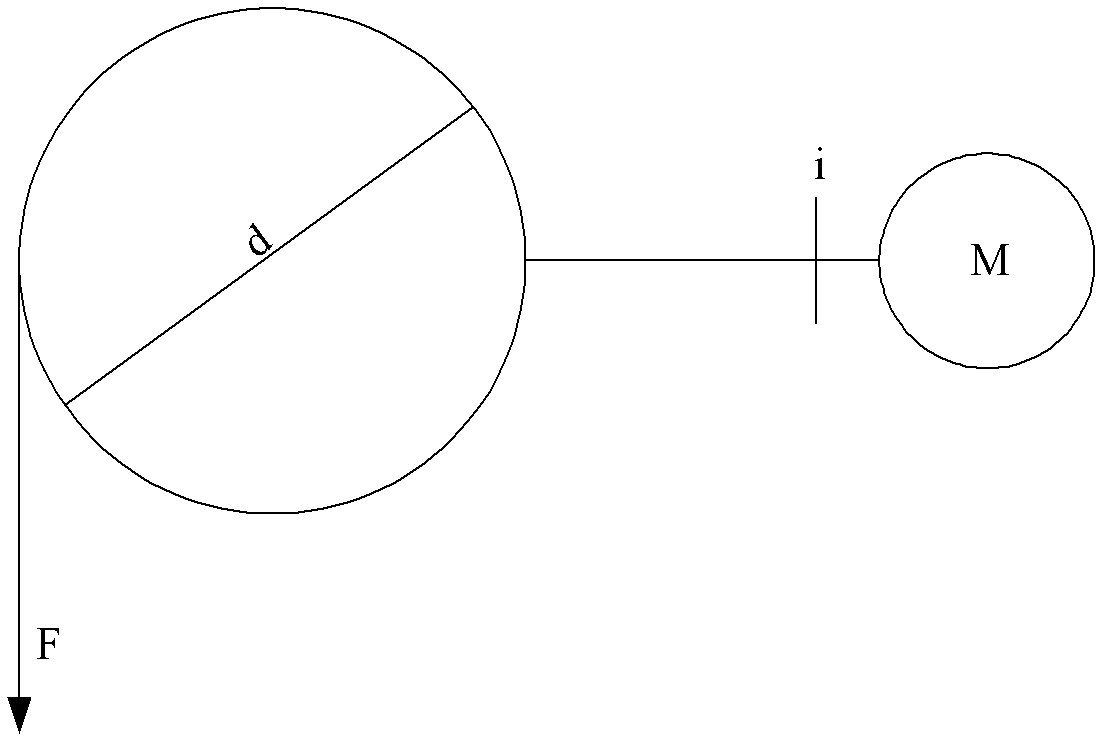

[0063] The purpose of the present invention is to overcome the defects of the existing methods for measuring the weight of coke. Aiming at the urgent need of coke production enterprises to grasp the weight information of coke produced by dry quenching, a new method for coke weight measurement is proposed, and a new method is designed on this basis. Coke weight real-time measurement and statistical analysis automation system.

[0064] Compared with the track scale method and belt scale method mentioned in the prior art, the present invention provides a method and system for obtaining coke weight based on a CDQ lifting device through the lifting and falling stages of the CDQ lifting device. The weight difference is used to calculate the precise weight of a single pot of coke in the CDQ furnace. It is characterized in that it does not need to install additional force sensing units to realize the conversion of red coke weight and output electrical signal, and then measure the weigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com