Manufacture and installation methods for shaft furnace feeding skew bridge

An installation method and technology of inclined bridges, which are applied in transportation and packaging, elevators in buildings, etc., can solve problems such as hidden dangers, difficulties in the installation quality of inclined bridges, and normal production of blast furnaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is described in detail below with reference to accompanying drawing and embodiment:

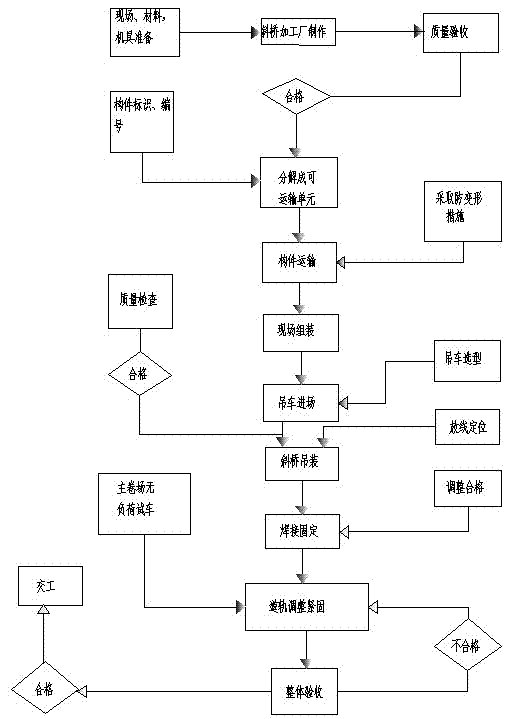

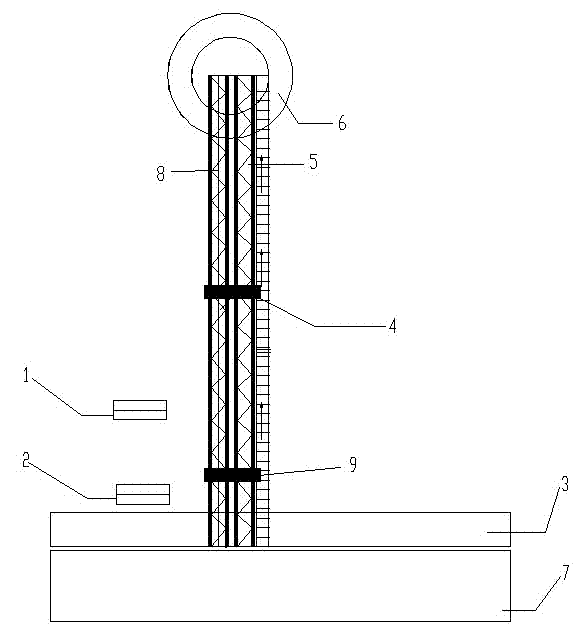

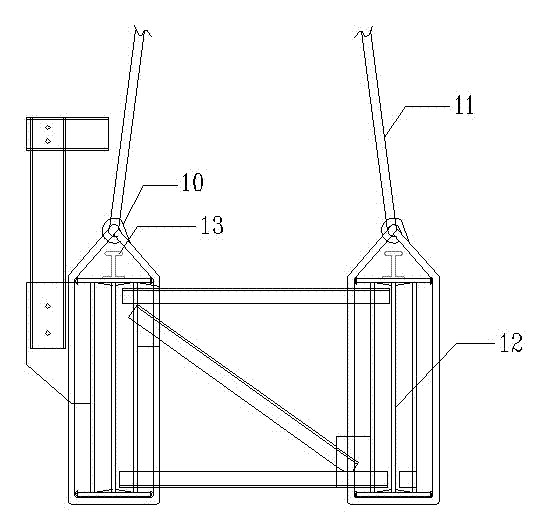

[0036] attached Figures 1 to 3 It can be seen that a manufacturing and installation method of a blast furnace loading inclined bridge includes: manufacturing the inclined bridge; transporting the inclined bridge; on-site assembly; calculation and selection of lifting equipment and spreaders and hoisting of the inclined bridge, the calculation and selection of the lifting equipment and spreaders The selection of the hoisting wire rope of the inclined bridge is determined by calculating the breaking force of the wire rope; the calculation formula is as follows:

[0037] Sling tension S = component weight ÷ the number of slings ÷ the sine of the angle between the sling and the horizontal plane;

[0038] The safety factor is K=8;

[0039] S≤the breaking force of the wire rope P÷safety factor K;

[0040] Check the manual to determine the size of the wire rope.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com