Welding machine

A technology for welding machines and welding parts, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc. It can solve the problems of time-consuming cleaning, hot welding head, easy to be stained with dirt, etc., and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

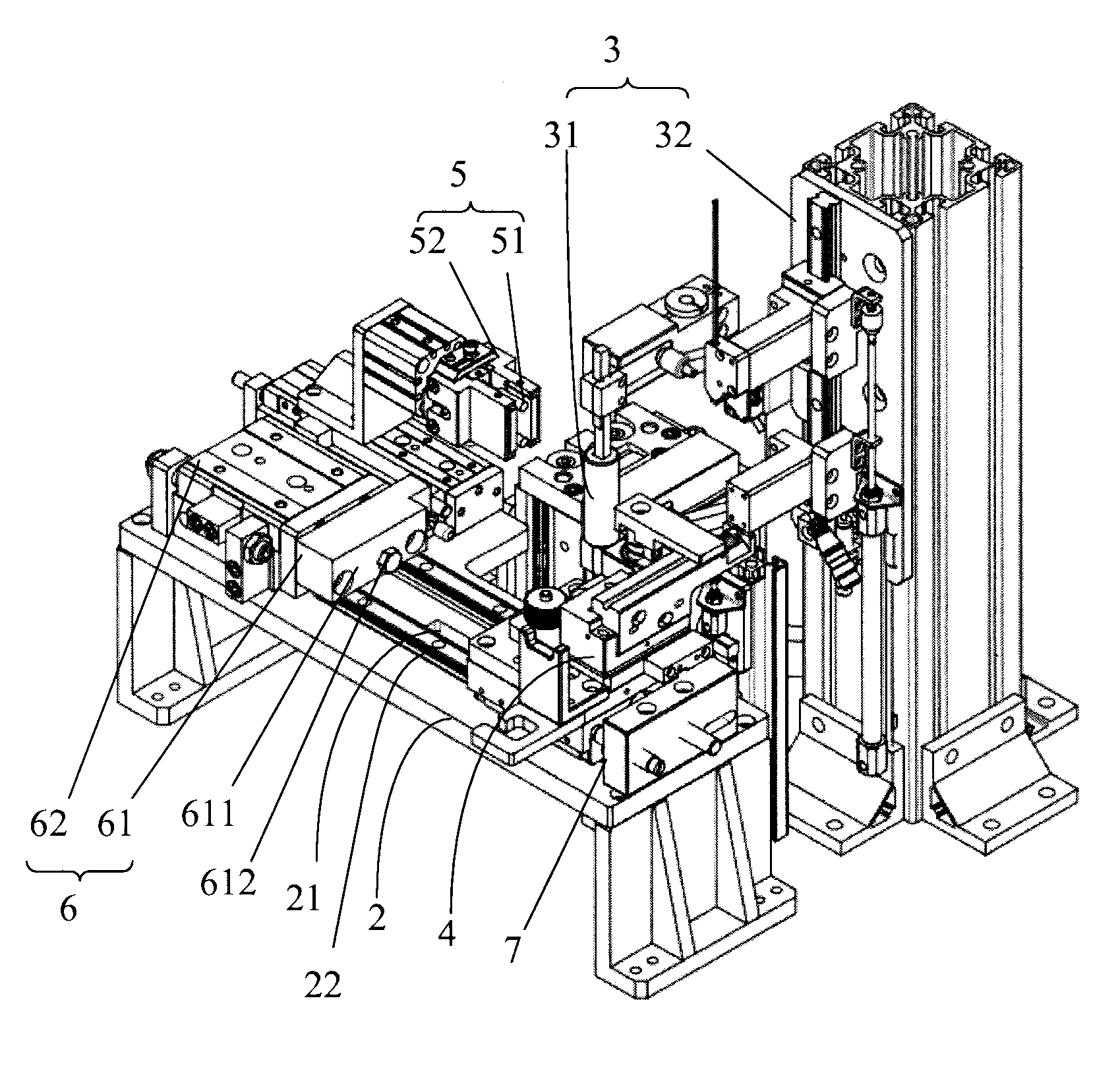

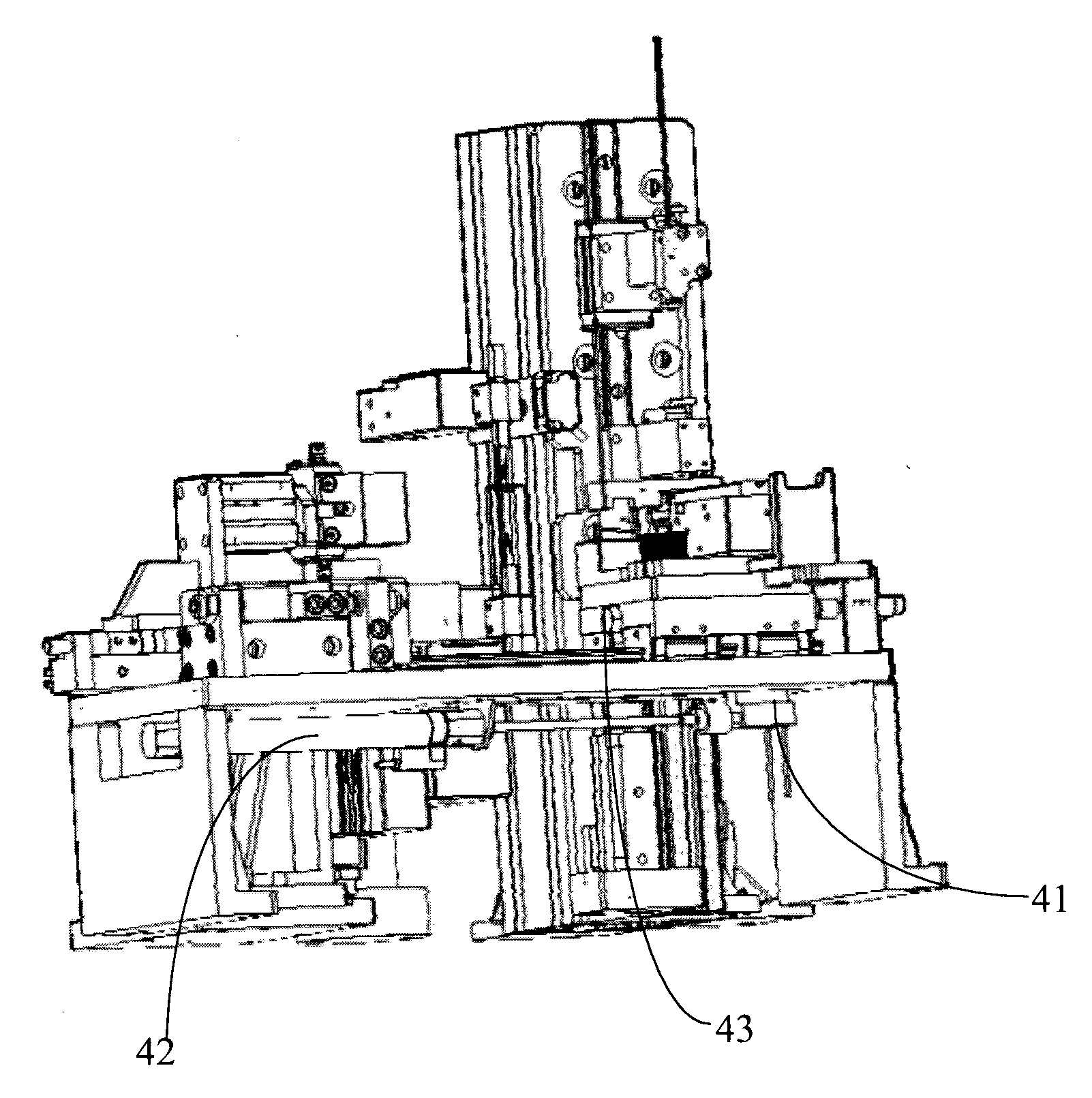

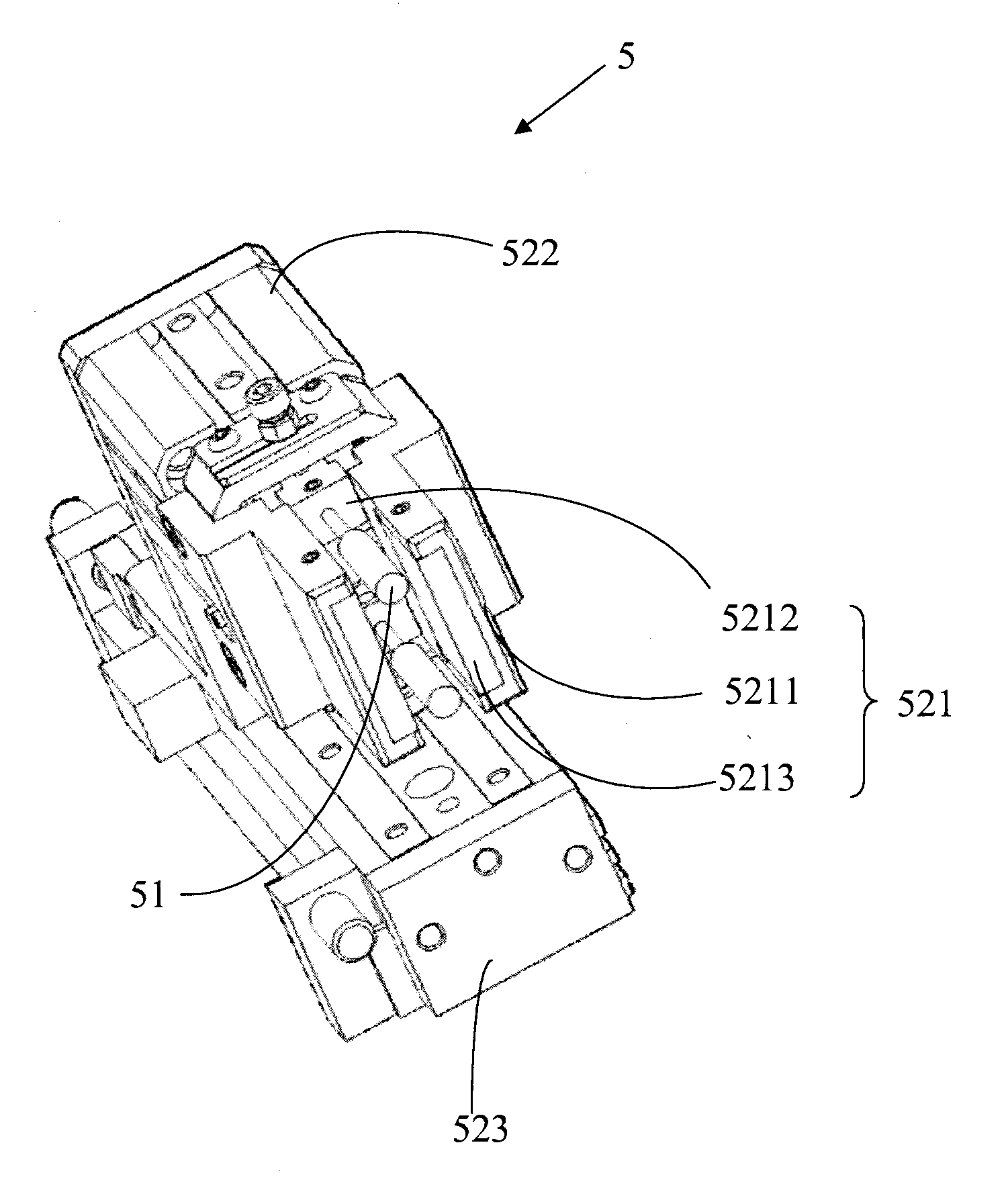

[0015] See figure 1 , a welding machine, including a base 2, a weldment clamping device 4 for clamping a weldment, a welding device 3 for welding a weldment, and a guide rail device 22 fixed on the base 2, a driving device 7, a limiter Positioning device 6 and cleaning electrode device 5, described welding device 3 comprises welding head 31 and the welding fixed support 32 that fixes this welding head 31, and welding fixed support 32 is positioned at base 2 side, and welding head 31 can move up and down to The weldment is welded, but it cannot be displaced left and right. The cleaning device 5 is used to clean the welding head 31. The cleaning device 5 has a cleaning component for cleaning the welding head 31. In this accompanying drawing, the The cleaning components include: a cleaning brush 51 and a cleaning sheet 5213 . When cleaning the welding head 31, the cleaning brush 51 and the cleaning sheet 5213 on the moving cleaning device 5 are used for cleaning, so as to preven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com