Rotary displacement pump for pumping solids emulsions, especially liquid explosives

A liquid explosive and rotary technology, applied in liquid fuel engines, rotary piston machinery, pumps, etc., can solve the problems of complex design, large size, and high cost, and achieve the goals of reducing material accumulation, efficient and safe operation, and avoiding injuries Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] When, the terms "front" and "back / rear" should be understood as referring to the axis of the shaft 8 in the accompanying drawings, and the terms "left" and "right" should be understood as referring to the axis of the shaft 8 in the accompanying drawings. rear (basically in the figure 1 right-hand side) to the front (basically in the figure 1 The left-hand side of the) when viewed with respect to the axis of shaft 8, thus, in figure 1 The parts of the pump on the side closer to the observer with respect to the axis 8 are on the "left" side, while on the figure 1 The parts of the pump on the side of the axis 8 farther from the observer are located on the "right" side.

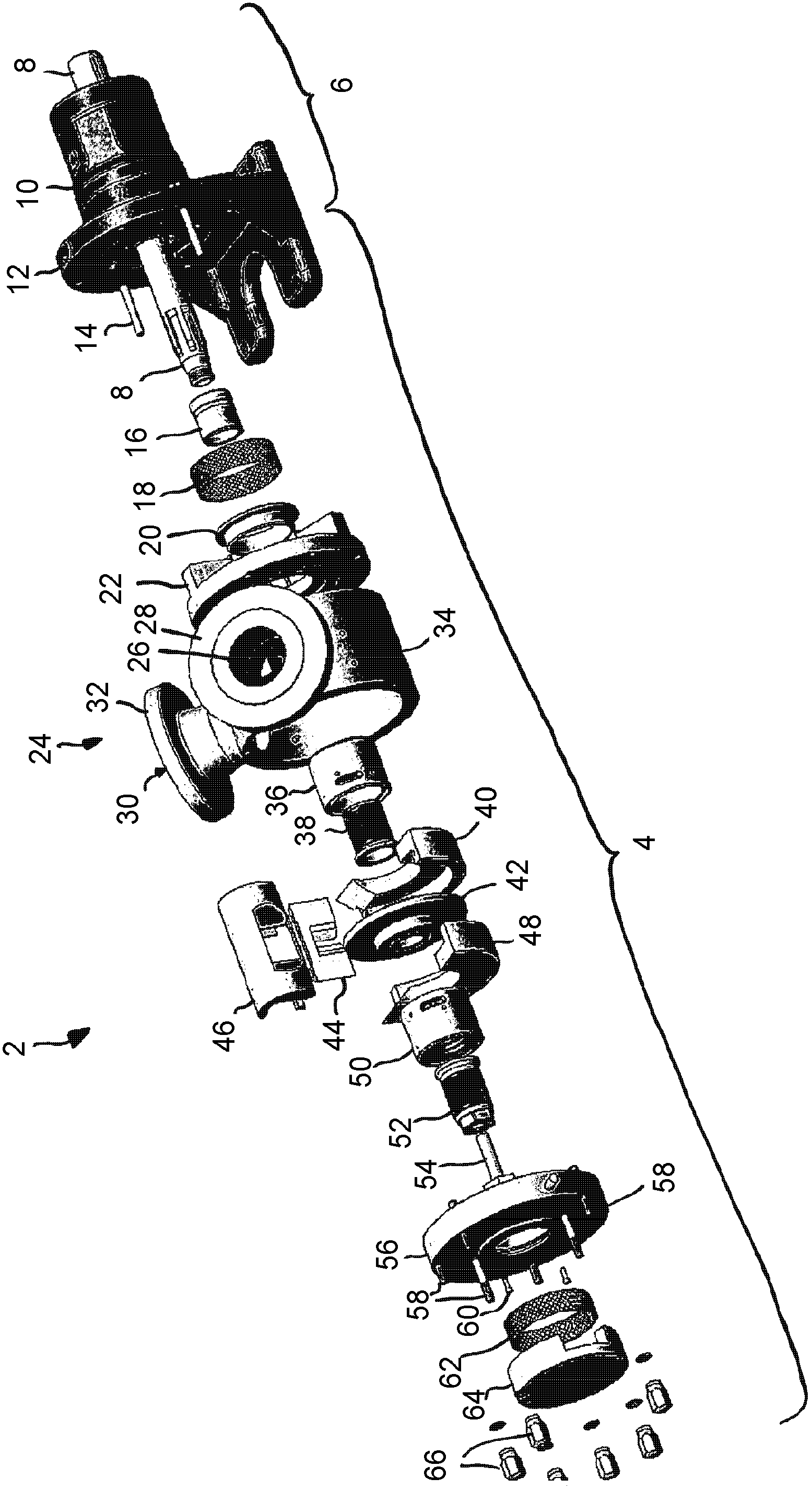

[0046] figure 1 The entire rotary displacement pump 2 is shown, comprising a pump part 4 or pump body 4 and a support part 6 .

[0047] exist figure 1 On the right-hand side of , the end of the shaft 8 protrudes from the support part 6 . A not shown drive motor, typically an electric motor, is used t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com