Boiler optimization method and device based on least squares support vector machine combustion model

A technology of support vector machine and least squares, which is applied to computer components, character and pattern recognition, instruments, etc., can solve the problems of long calculation time, complicated process, and low real-time performance adjustment of power station boilers, etc., to achieve reduction and optimization Difficulty, the effect of improving real-time performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

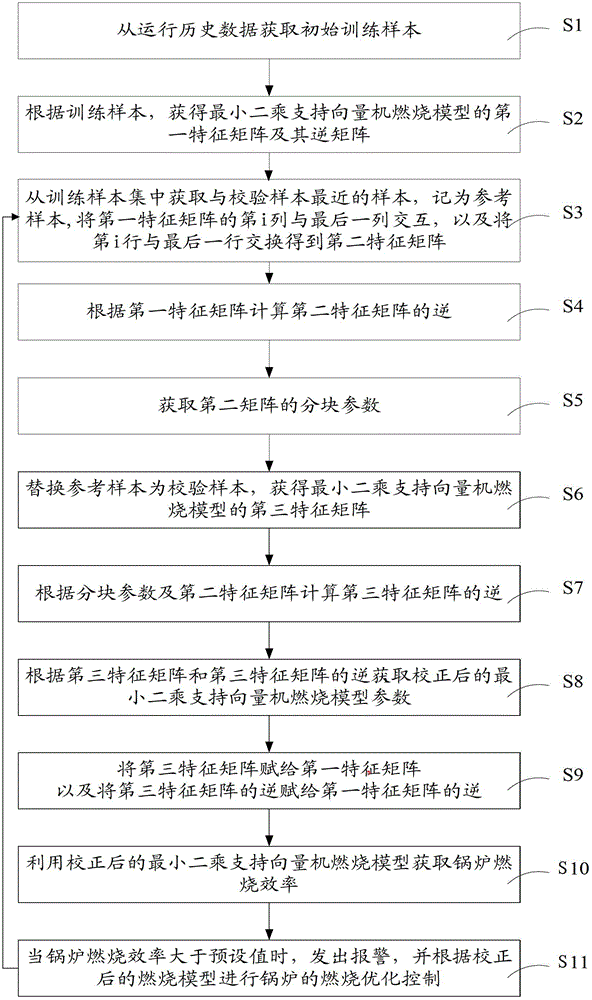

[0035] Please refer to figure 1 , the boiler optimization method based on the least squares support vector machine combustion model that the present invention proposes, comprises steps:

[0036] S1. Acquiring initial training samples from operation history data;

[0037] A training sample set is formed by extracting samples from unit operation history data or field test data, and the training sample set includes the input quantity and the measured output quantity of the least squares support vector machine combustion model.

[0038] S2. Obtain the first feature matrix and its inverse matrix of the least squares support vector machine combustion model according to the training samples;

[0039] Obtain the first feature matrix H and its inverse matrix H of the least squares support vector machine combustion model by learning the training sample set -1 ;

[0040] S3. Obtain the sample closest to the verification sample from the training sample set, and record it as a reference...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com