Automobile heat radiator wind tunnel experiment device for simulating actual operation working condition

An automotive radiator, the actual operation technology, applied in the direction of measurement device, aerodynamic test, machine/structural component test, etc., can solve the problem of unable to meet the test requirements, unable to simulate the ambient temperature, etc., to shorten the design cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. It should be noted that the following description is only for explaining the present invention and not limiting its content.

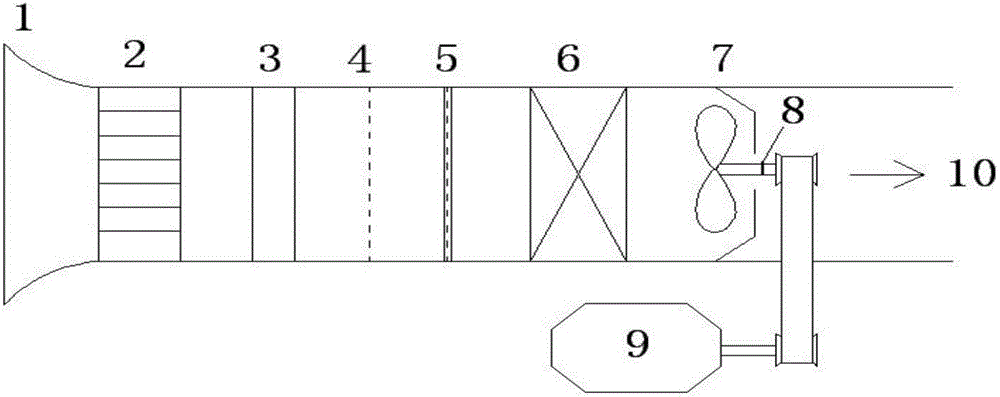

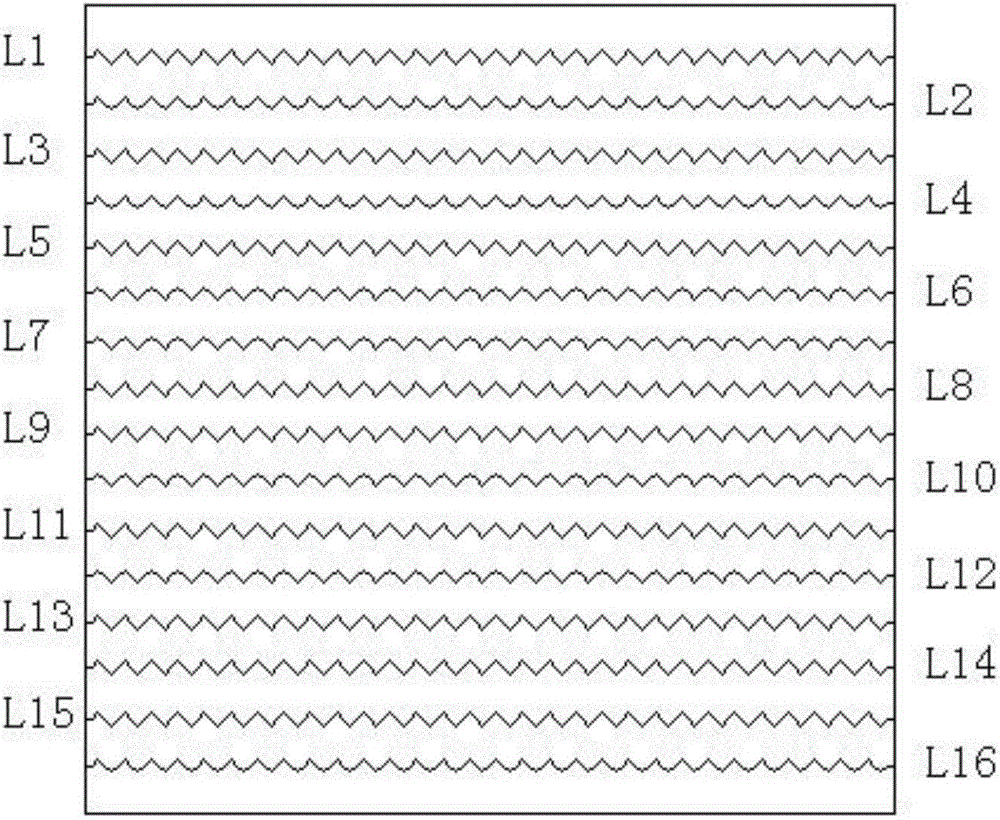

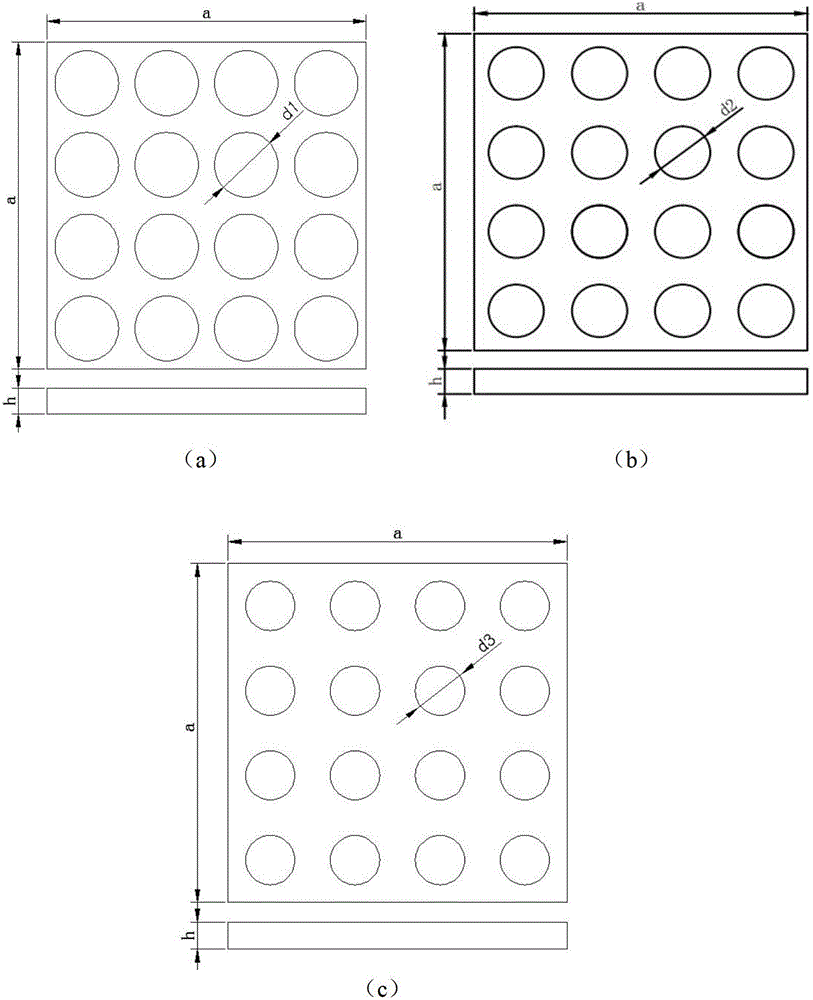

[0031]A car radiator wind tunnel test device for simulating actual operating conditions, including a cave body, in the direction of the air intake inside the cave body, an air intake heating and control device 2, a throttle orifice plate 3, a stabilizing section 4 and a measuring The temperature device 5, the radiator module 6, the fan 7 provided with the rotational speed measuring device 8, and the fan 7 communicates with the outside atmosphere. The radiator module 6 includes one or more of a water radiator, a supercharged intercooler or an oil radiator. The air intake heating and control device 2 includes 16 rows of resistance wires, and the number of energized resistance wires and the magnitude of the current can be adjusted, s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap