Composite HBF (Honess Hybrid Biological&Fixed film Technology) module reactor and sewage treatment process

A reactor and composite technology, applied in the field of composite HBF module reactor and sewage treatment process, can solve the problems of mismatch between incoming water and intermittent incoming water, large adjustment tank of SBR reactor, large loss of sewage lifting resistance, etc. Achieve the effects of easy on-site assembly, saving investment and operating costs, and high volume load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

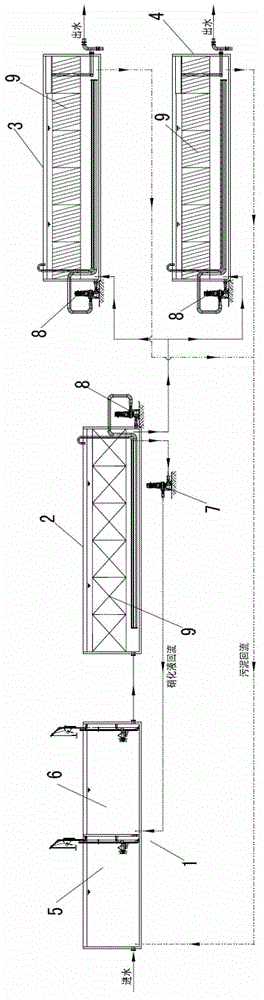

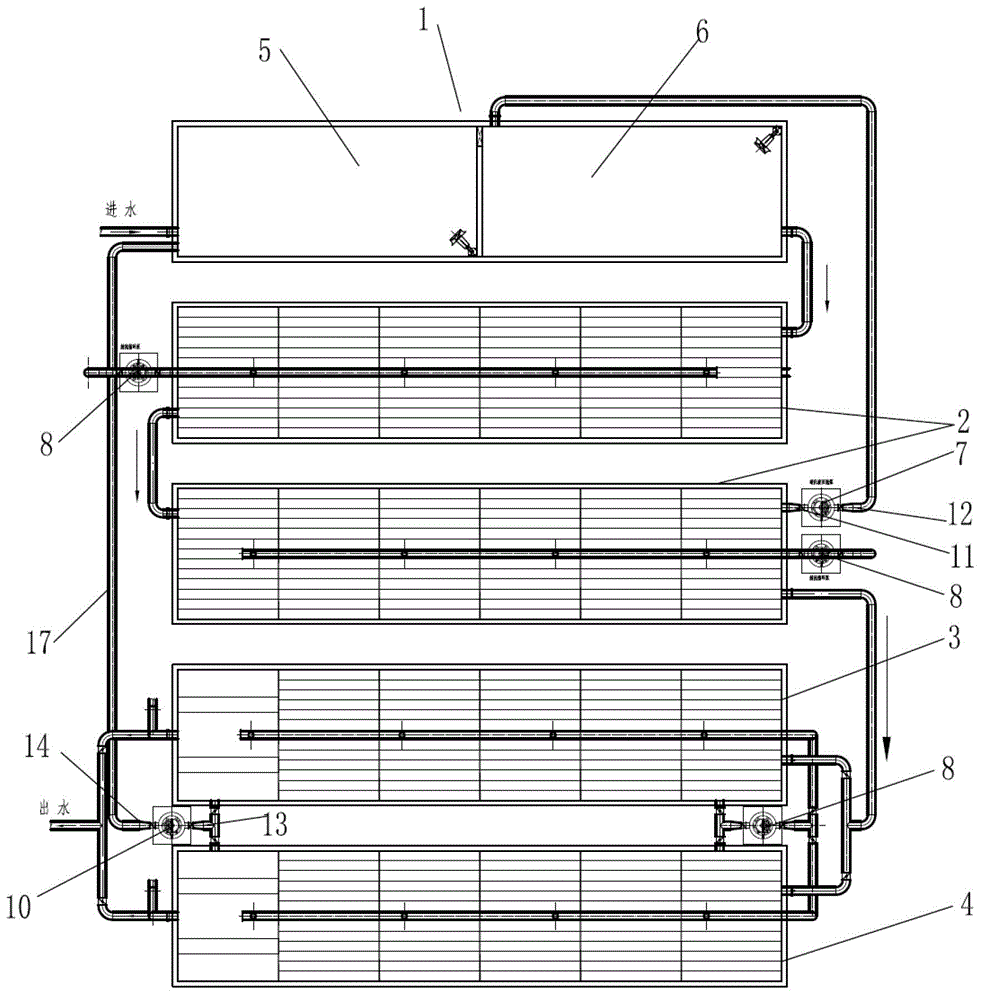

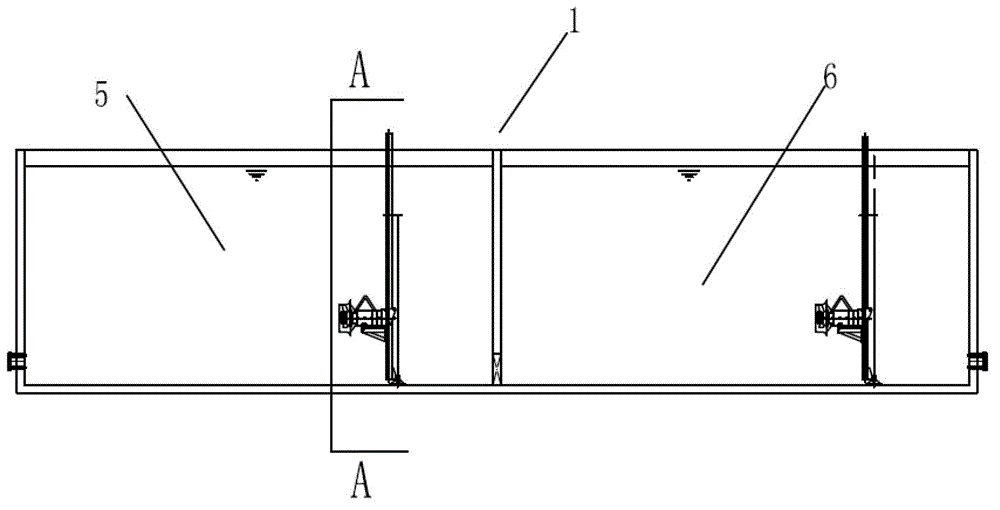

[0054] A composite HBF module reactor of this embodiment includes an anaerobic tank, an anoxic tank, an aerobic tank, and an SBR tank that are sequentially connected; wherein the SBR tank includes a first SBR tank and a second SBR tank, The first SBR tank and the second SBR tank are simultaneously connected with the aerobic tank, and the aerobic tank, the first SBR tank and the second SBR tank are respectively provided with enzyme floating fillers.

[0055] Specifically, the enzyme floating filler described in this embodiment can be manufactured by using the announcement number CN101633529B and the name is "Method for Manufacturing Ionic Enzymatic Suspended Filling Applied to Treatment of Highly Difficult Wastewater" (hereinafter referred to as the announcement document).

[0056] Exemplarily, the enzyme floating filler used in this embodiment is made according to the teaching in the announcement document with the announcement number CN101633529B, specifically using the method taugh...

Embodiment 2

[0068] Picture 12 Flow chart of sewage treatment process. This embodiment proposes a sewage treatment process using the composite HBF module reactor of the first embodiment, and the components are assembled and connected according to the description of the first embodiment to form a figure 1 with figure 2 The composite HBF modular reactor shown, combined with Picture 12 As shown, perform the following steps in sequence:

[0069] Step S1: The sewage is introduced into the anaerobic zone 5 of the anaerobic and anoxic module 1 through the sewage inlet pipe, and is stirred and mixed with the sludge conveyed by the sludge return device 10 in the anaerobic zone 5 to complete the anaerobic release phosphorus. Exemplarily, a submersible mixer is built in the anaerobic zone 5 for mixing.

[0070] Step S2: The sewage in the anaerobic zone 5 is introduced into the anoxic zone 6, and mixed with the liquid returned by the nitrification liquid reflux pump 7, while adding nitrate nitrogen for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com