Magnetostrictive Composite Cantilever Actuated by Terfenol-d Flakes

A technology of magnetostrictive and composite cantilever beams, applied in piezoelectric/electrostrictive/magnetostrictive devices, piezoelectric devices/electrostrictive devices, microstructure devices composed of deformable elements, etc., can Solve the problems of Galfenol alloy and giant magnetostrictive film with small deformation, low power density, and limited use, and achieve the effects of large output deformation, fast response speed, and high power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

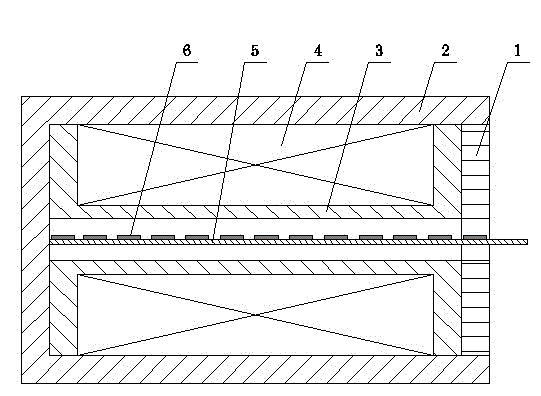

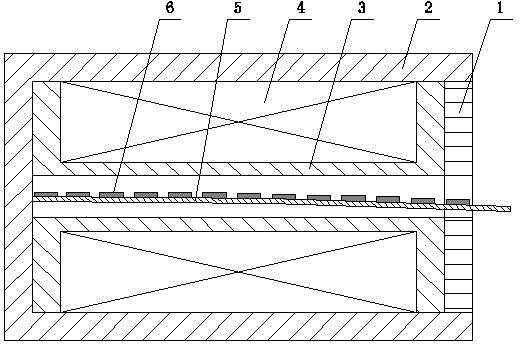

[0016] A magnetostrictive composite cantilever beam driven by a Terfenol-D sheet, comprising a magnetically conductive shell 2, a magnetically conductive end cover 1, a non-magnetically conductive coil skeleton 3, a magnetically conductive shell 2, a magnetically conductive end cover 1, a nonmagnetically conductive The magnetic coil bobbins 3 are all circular axisymmetric structures, one end of the magnetically conductive shell 2 is sealed, and the other end is open, and the magnetically conductive end cover 1 is installed on the open end, and the non-magnetically conductive coil bobbin 3 is arranged in the magnetically conductive shell 2. A coil 4 is wound on the magnetic coil bobbin 3, the magnetic end cover 1 and the non-magnetic coil bobbin 3 are provided with a central axis hole, and the straight non-magnetic conductive elastic substrate 5 is arranged on the central axis of the non-magnetic conductive coil bobbin 3 On the central axis in the hole, one end is fixed on the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com