Piezoelectric single crystal driver and preparation method thereof

A piezoelectric single crystal and driver technology, applied in piezoelectric devices/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, circuits, etc., can solve high cost, low yield and unusable drivers and other problems, to achieve the effect of less layers, large output deformation, and large displacement output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0027] Such as Figure 1 to Figure 4 As shown, a piezoelectric single crystal driver provided by the present invention includes a piezoelectric single crystal stack 1, a wire 2 and an insulating end cap 3, wherein the upper and lower ends of the piezoelectric single crystal stack 1 are provided with wires; Insulating end caps 3 are respectively provided at both ends of the piezoelectric single crystal stack 1 along its length direction.

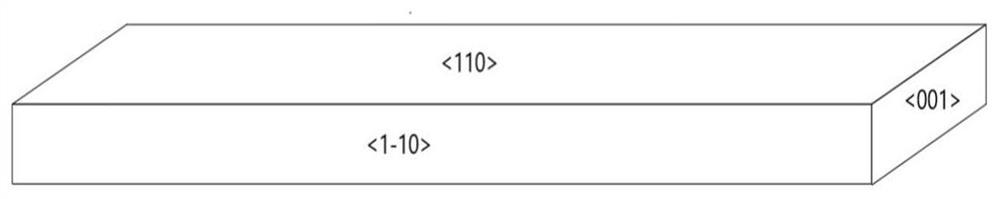

[0028] The piezoelectric single crystal stack 1 includes a plurality of single crystals 101, and the multiple single crystals 101 are attached and stacked in series in structure and parallel in circuit.

[0029] The single chip is arranged in a stacked manner, mainly to reduce the driving voltage; from the output displacement of the driver D=d32*(U / t)*L, it can be seen that when d32 and the length are determined, the thickn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com