Special bracket for integrally hoisting marine main engine cylinder body and air cooler and method for integrally hoisting marine main engine cylinder body and air cooler

A technology of integral hoisting and ship main engine, applied in the directions of transportation and packaging, load hoisting components, etc., can solve the problems of increasing personal safety hazards, affecting the sealing of contact surfaces, and occupying a long time for high hoisting, so as to shorten the hoisting time and ensure Effects of tightness requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

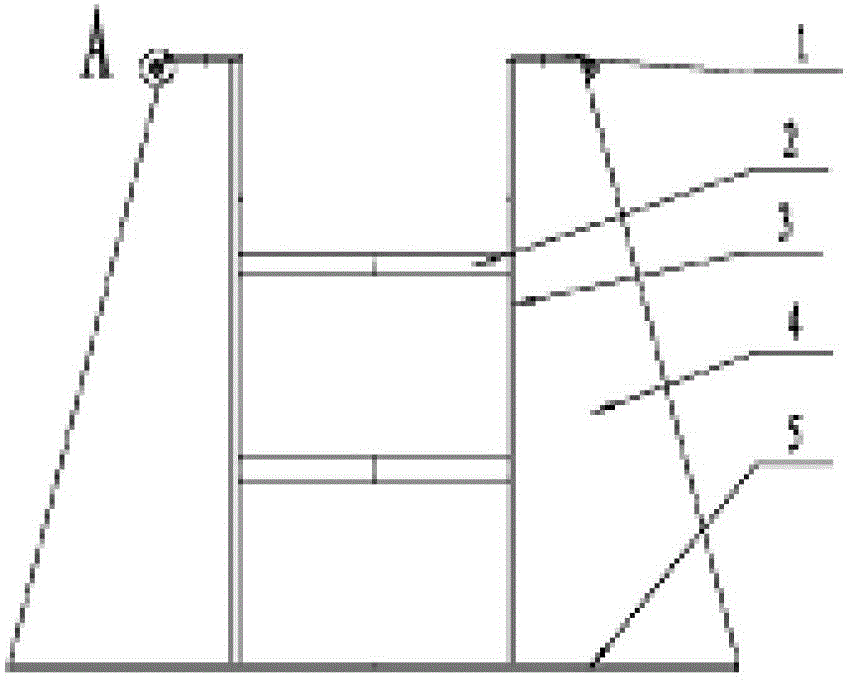

[0032] The implementation of the method of the present invention will be described in detail below by taking the overall shipping and hoisting process of the main engine cylinder block and air cooler of a 76,000-ton bulk carrier.

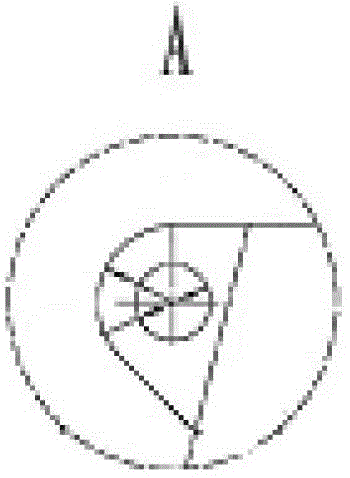

[0033] The main engine model in this embodiment is: 5S60MC-C, the gross weight of the cylinder block 01 and the air cooler 02 assembly: 131.8T (with special bracket 03); external dimensions: 8700×7500×7600 (length×width×height); center of gravity Position: 2185mm axially from the centerline of 1# cylinder (toward the thrust end), 291mm laterally from the centerline of the cylinder body (toward the exhaust side), and 4000mm from the bottom of the special bracket 03 (the height of the special bracket 03 is 2500mm); Lifting point layout: 1# cylinder and 5# cylinder (lifting point opening 4080mm).

[0034] In this embodiment, the main engine cylinder block 01 and the air cooler 02 are shipped and hoisted as a whole, as follows:

[0035] Step 1: Disas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com