An automatic sorting device for missing rods in cigarette boxes in cigarette logistics

An automatic sorting and smoke box technology, applied in the direction of automatic packaging control, packaging, packaging protection, etc., can solve the problems of labor-intensive, complaining, and troublesome inspection, and achieve the effect of high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings.

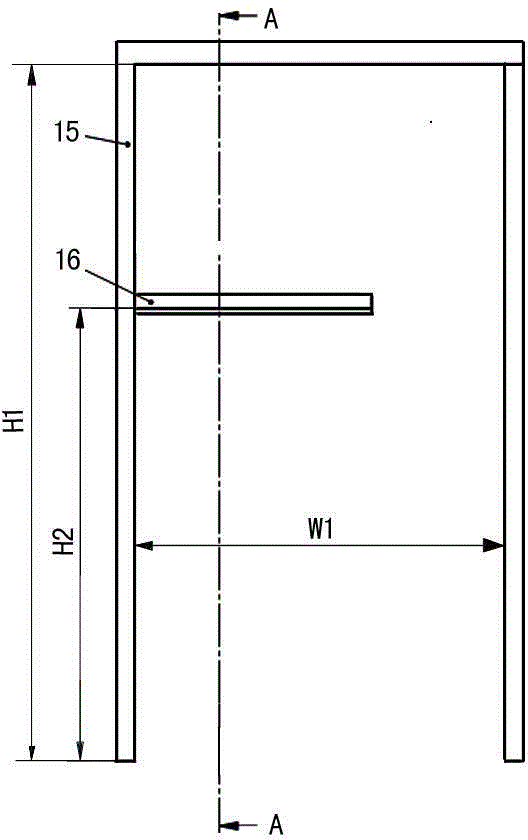

[0020] Referring to each figure, the strip detection instrument 11 is installed on the logistics line logistics conveyor belt 17 of the cigarette out of the warehouse. The door frame bracket 15 is installed downstream, the solenoid valve 22 is installed at the bottom of the door frame bracket 15, the bar code information shielding mechanism is installed on the support rib 16 of the door frame bracket 15, the bar code scanner 14 is installed on the top of the door frame bracket 15, and the lower part of the lens surface is aligned with the smoke box barcode12.

[0021] The barcode 12 of the embodiment “Yuxi” cigarette has a size of 105mm×75mm, and is pasted on the surface of the cigarette box 13, and the shortest distance from the two corners of the box is about 50mm.

[0022] The structure of the barcode information shielding mechanism is detailed in figure 2 As s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com