A kind of green low-radiation energy-saving glass

A low-emissivity coating and white glass substrate technology, applied in the direction of glass/slag layered products, layered products, chemical instruments and methods, etc., can solve the problems of greenish transmission color and high cost of low-emissivity glass, and achieve stability Good performance, high commercial value, and the effect of reducing scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

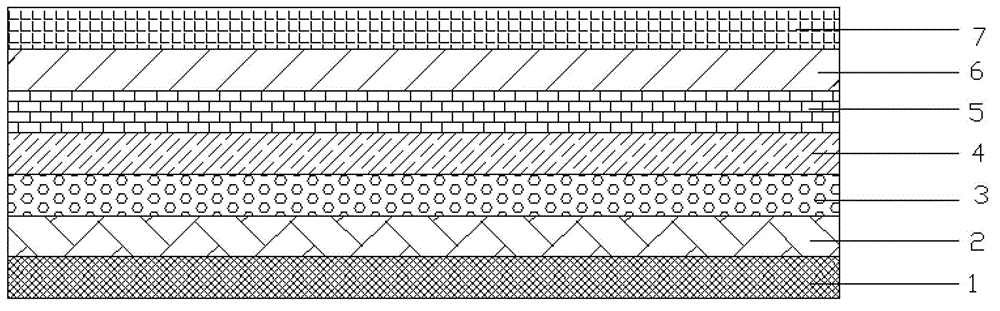

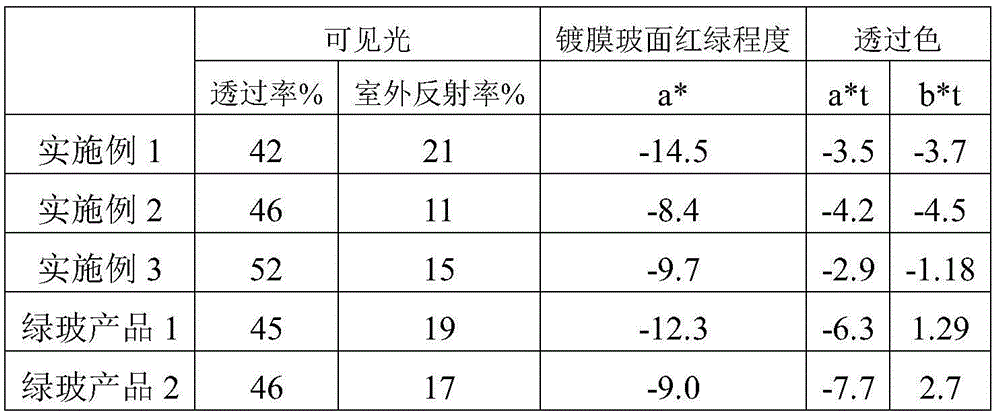

[0026] Select 6mm high-quality high-quality float white glass substrate (1), and use the vacuum magnetron cathode sputtering method to coat the film. From the inside to the outside, the film system is as follows: the first layer (2) uses silicon nitride with a thickness of 8nm, and the second layer (3 ) adopts nickel-chromium with a thickness of 10nm, the third layer (4) adopts zinc tin oxide with a thickness of 78nm, the fourth layer (5) adopts silver Ag with a thickness of 9nm, the fifth layer (6) adopts nickel-chromium with a thickness of 3.6nm, and the sixth layer (7 ) using silicon nitride with a thickness of 20nm.

Embodiment 2

[0028] Select 6mm high-quality high-quality float white glass substrate, and use vacuum magnetron cathode sputtering method to coat the film. From the inside to the outside, the film system is as follows: the first layer is made of silicon nitride with a thickness of 11nm, the second layer is made of nickel chromium with a thickness of 7nm, and the third layer is made of nickel chromium with a thickness of 7nm. The first layer is made of silicon nitride with a thickness of 67nm, the fourth layer is made of silver Ag with a thickness of 6.5nm, the fifth layer is made of nickel chromium with a thickness of 3.3nm, and the sixth layer is made of zinc aluminum oxide with a thickness of 20nm.

Embodiment 3

[0030] Select 6mm high-quality high-quality float white glass substrate, and use vacuum magnetron cathode sputtering method to coat the film. From the inside to the outside, the film system is as follows: the first layer is made of silicon nitride with a thickness of 7nm, the second layer is made of nickel chromium with a thickness of 7nm, and the third layer is made of nickel chromium with a thickness of 7nm. The first layer is made of zinc tin oxide with a thickness of 69nm, the fourth layer is made of silver Ag with a thickness of 6nm, the fifth layer is made of nickel chromium with a thickness of 2nm, and the sixth layer is made of silicon nitride with a thickness of 20nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com