Numerical control system-based tool grinding method, device and system

A numerical control system and tool technology, applied in the field of tool processing, can solve the problems of unsatisfactory processing efficiency, large number of molds, and high production cost, and achieve the effect of ideal tool processing effect, reduction of production cost, and high processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

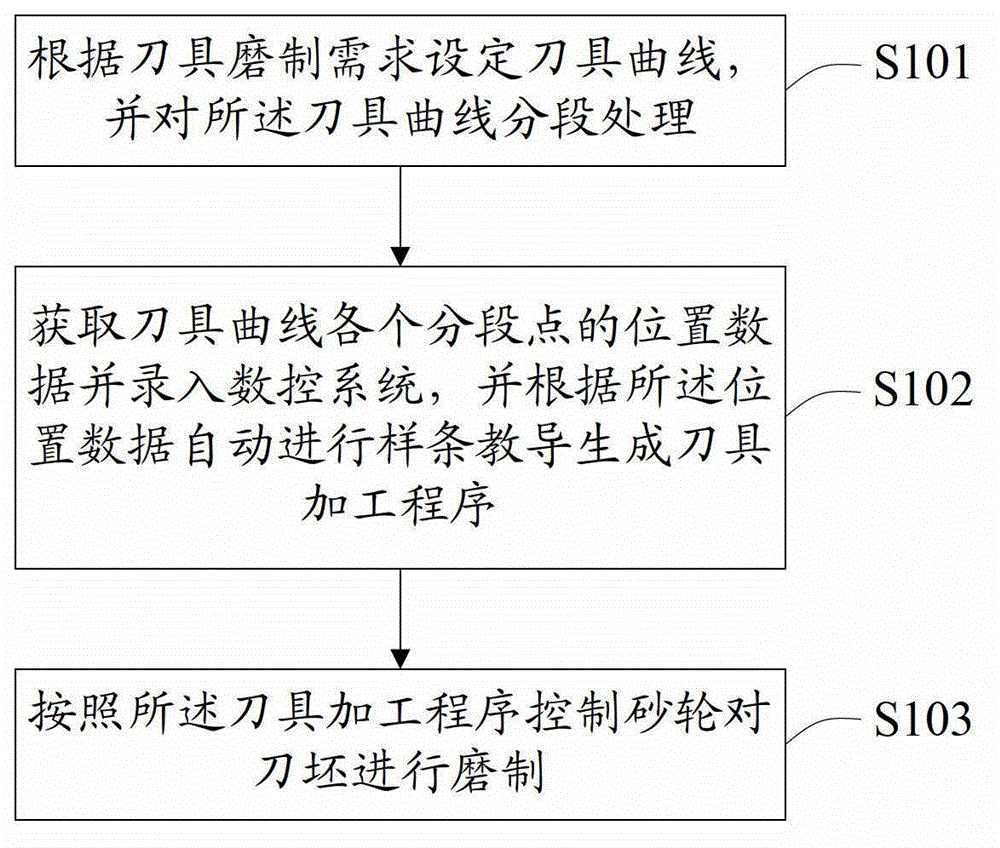

[0027] figure 1 The flowchart of the tool grinding method based on the numerical control system provided by the first embodiment of the present invention is shown, and only the parts related to the embodiment of the present invention are shown for convenience of description.

[0028] The tool grinding method based on the numerical control system provided in this embodiment includes:

[0029] Step S101 , setting a tool curve according to tool grinding requirements, and processing the tool curve in segments.

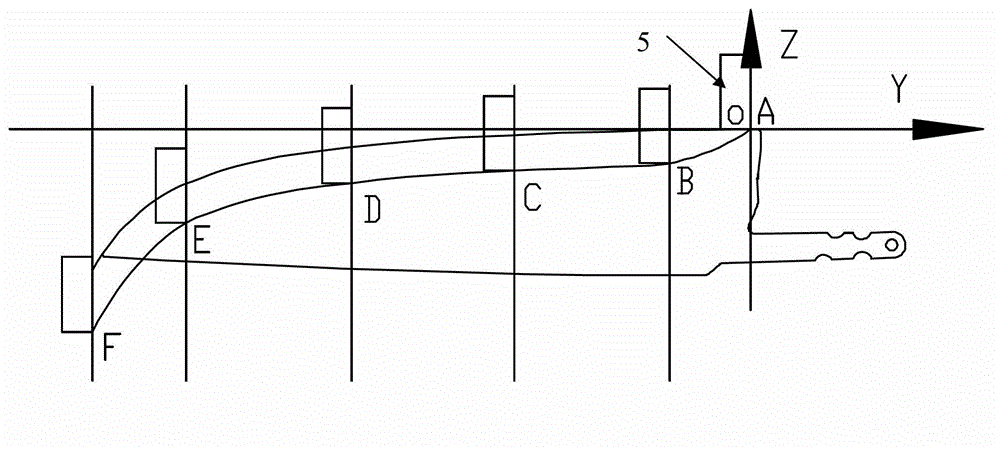

[0030] The tool curve is the path that the grinding wheel takes when grinding the tool. When grinding different tools, the tool curve is different, such as figure 2 As shown, assuming that a kitchen knife needs to be sharpened at present, the knife curve of the kitchen knife must be drawn first, and then the knife curve is divided into multiple segments. The specific segmentation is determined by the trend of the knife curve. Some, the subsections can be sparser in plac...

Embodiment 2

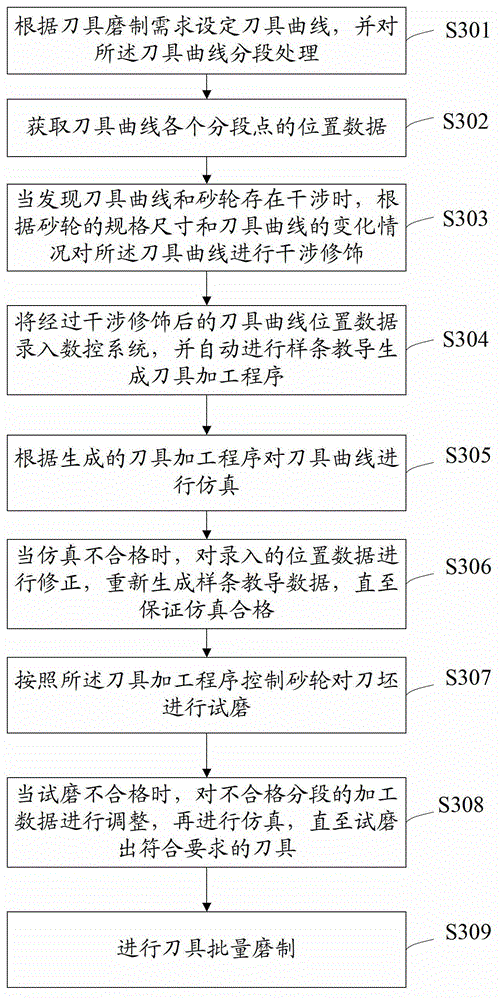

[0037] image 3 The flowchart of the tool grinding method based on the numerical control system provided by the second embodiment of the present invention is shown, and only the parts related to the embodiment of the present invention are shown for convenience of description.

[0038] The tool grinding method based on the numerical control system provided in this embodiment includes:

[0039] Step S301, setting a tool curve according to tool grinding requirements, and processing the tool curve in segments;

[0040] Step S302, obtaining the position data of each segment point of the tool curve;

[0041] Step S303, when it is found that there is interference between the tool curve and the grinding wheel, perform interference modification on the tool curve according to the size of the grinding wheel and the change of the tool curve;

[0042] Step S304, inputting the position data of the tool curve after the interference modification into the numerical control system, and automa...

Embodiment 3

[0053] Figure 8 The structure of the tool grinding device based on the numerical control system provided by the third embodiment of the present invention is shown, and only the parts related to the embodiment of the present invention are shown for convenience of description.

[0054] The tool grinding device based on the numerical control system provided in this embodiment includes:

[0055] A curve segmentation unit 801, configured to set the tool curve according to the tool grinding requirements, and segment the tool curve;

[0056] The program generation unit 802 is used to obtain the position data of each segment point of the tool curve and enter it into the numerical control system, and automatically perform spline teaching according to the position data to generate a tool processing program;

[0057] The tool grinding unit 803 is used to control the grinding wheel to grind the tool blank according to the tool processing program.

[0058] Each functional unit 801-803 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com